Preparation method of prop-1-ene-1, 3-sultone

A technology of sultone and propylene, which is applied in the field of preparation of organic materials, can solve the problems of low yield of cyclosynthesis products and slow reaction speed, and achieve the effects of high yield, fast reaction speed and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

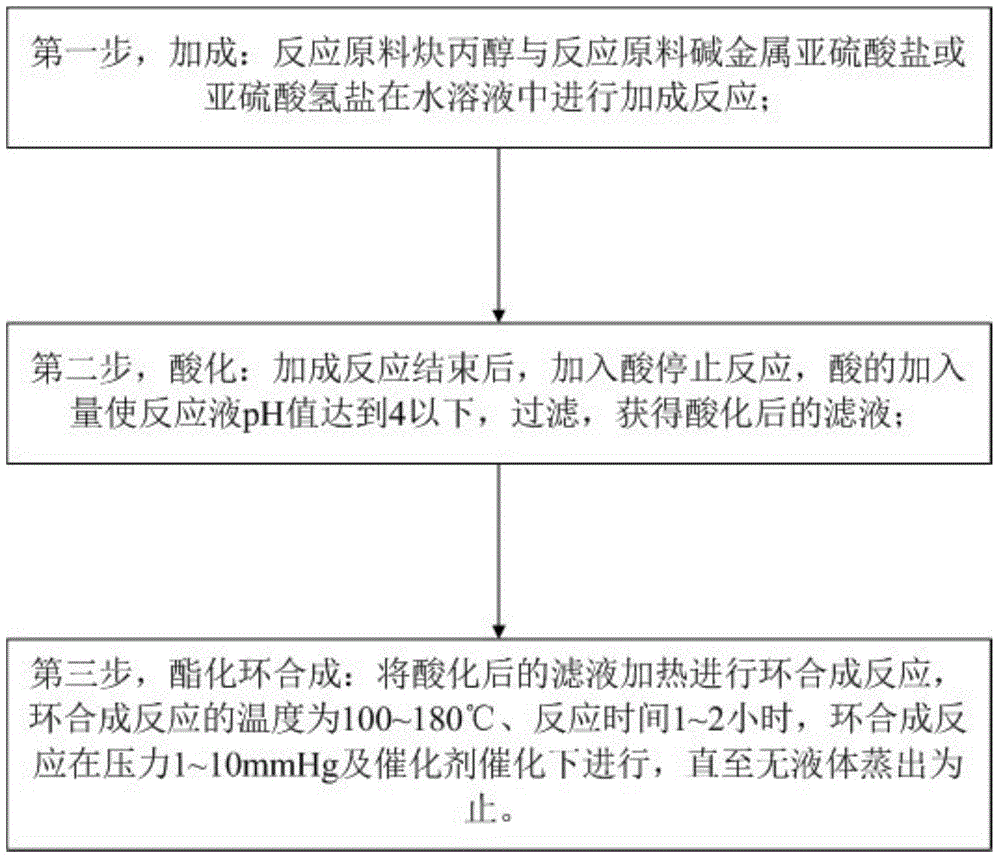

[0030] Such as figure 1 Shown: a kind of preparation method of 1-propene-1,3-sultone, comprising the following steps:

[0031] The first step, add:

[0032] The reaction raw material propargyl alcohol and the reaction raw material alkali metal sulfite or bisulfite carry out addition reaction in aqueous solution;

[0033] The second step, acidification:

[0034] After the addition reaction is finished, add acid to stop the reaction, the amount of acid added makes the pH value of the reaction solution reach below 4, filter to obtain the acidified filtrate;

[0035] The third step, esterification ring synthesis:

[0036] Heating the acidified filtrate to carry out the cyclosynthesis reaction, the temperature of the cyclosynthesis reaction is 100-180°C, the reaction time is 1-2 hours, the cyclosynthesis reaction is carried out under the pressure of 1-10mmHg and catalyst catalysis, until no liquid is evaporated.

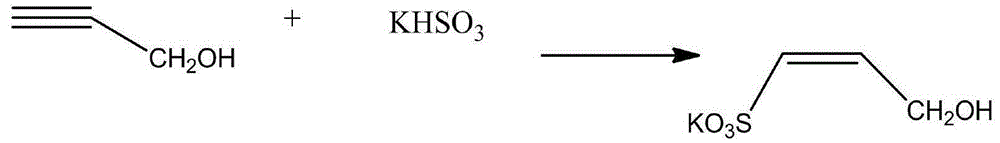

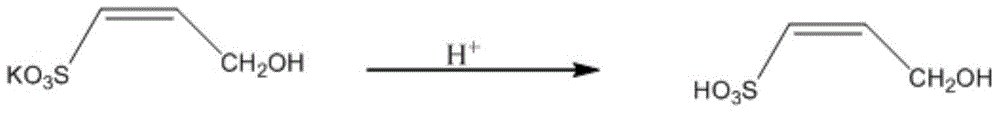

[0037] The reaction equation for the addition reaction is:

[0...

Embodiment 1

[0060] Example 1: Select 200 g of the filtrate after salt extrusion (i.e. after acidification) prepared as above, the catalyst is 5 g of hydrochloric acid gas, and cyclize under a vacuum of 10 mmHg for 1 to 2 hours, and separate according to the separation technology in the comparative example, and finally obtain PST crude product 133g, yield is 77.7%.

[0061] The above catalyst hydrochloric acid can be replaced by an equivalent amount of sulfuric acid, phosphoric acid, nitric acid or gaseous mineral acid.

Embodiment 2

[0062] Example 2: Select 200 g of the filtrate after salt extrusion (i.e. after acidification) prepared as above, the catalyst is 5 g of hydrochloric acid gas, and ring-close for 1 to 2 hours under a vacuum of 1 mmHg, and separate according to the separation technology in the comparative example, and finally obtain PST crude product 139g, yield is 81.2%.

[0063] The above catalyst hydrochloric acid can be replaced by an equivalent amount of sulfuric acid, phosphoric acid, nitric acid or gaseous mineral acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com