Silicon-containing polycarboxylate superplasticizer as well as preparation method and use thereof

A technology of silicon polycarboxylate and water reducer, applied in the field of silicon-containing polycarboxylate water reducer, can solve the problems of reducing the molecular utilization rate and dispersibility of polycarboxylate water reducer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] Illustrate that the preparation method of the silicone anti-mud type polycarboxylate water reducer provided by the present invention comprises the following steps:

[0048] 1) Synthesis of large molecular size organosilicon monomer:

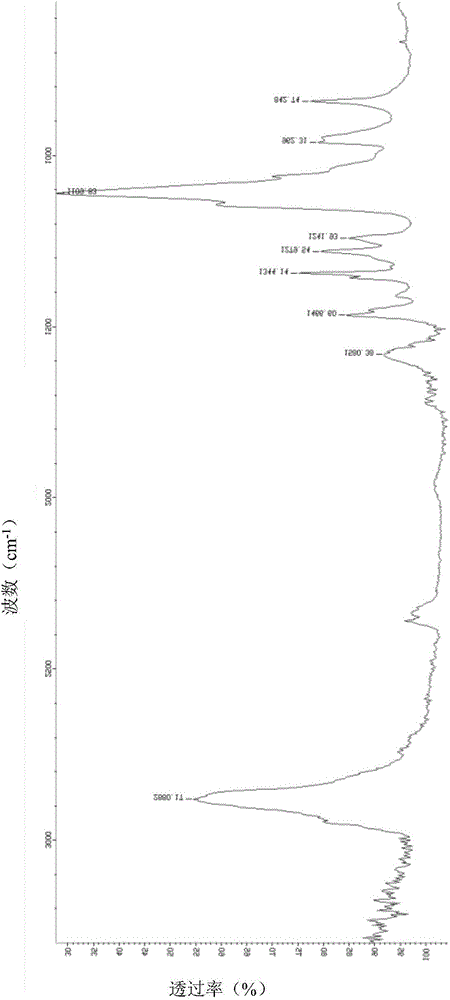

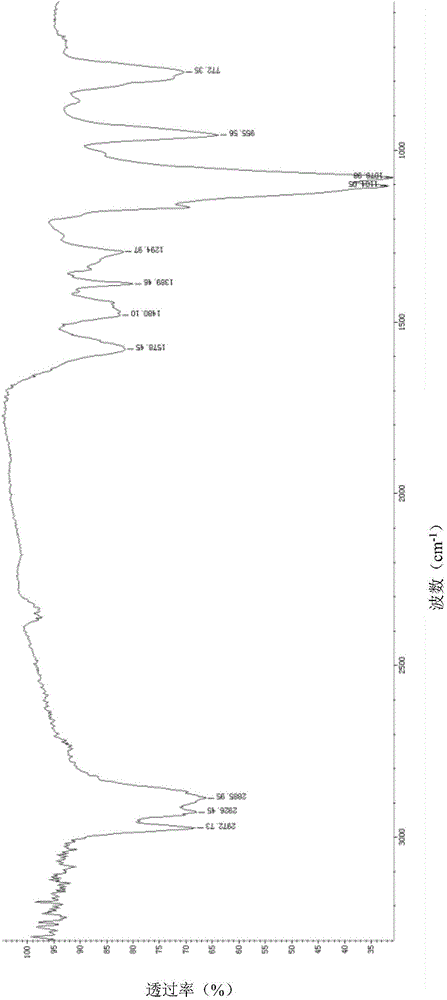

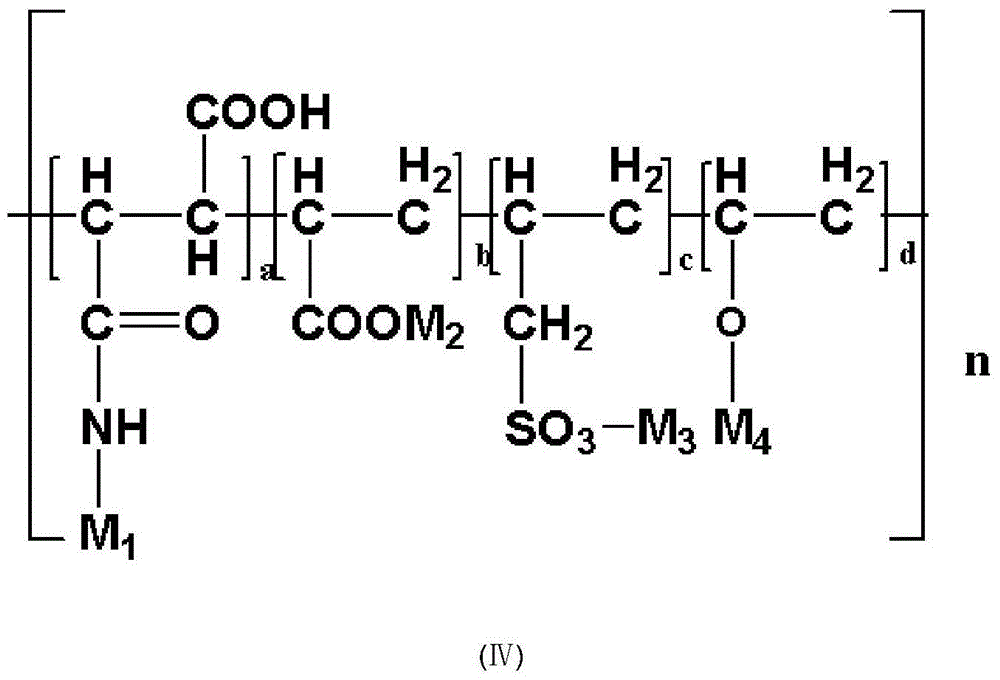

[0049] Organic silicon groups are introduced into the polymer structure. The molecular structure of organic silicon raw materials used is shown in Figure (I), and the molecular structure of organic silicon with active double bonds is shown in Figure (II). The unsaturated monomer structure is shown in Figure (Ⅲ);

[0050]

[0051] The prepared silicon-containing polycarboxylate water reducer is shown in structural formula (IV):

[0052]

[0053]This step is a chemical reaction between the silane coupling agent aminopropyltriethoxysilane (KH-550) and dry maleic anhydride under cooling conditions, and introduces a C=C double bond structure into the KH-550 molecule through an amide bond ; Then under the catalysis of the ethanol solutio...

Embodiment 1

[0064] Add 200g of dry maleic anhydride into the three-necked flask, slowly and uniformly add 250g of silane coupling agent KH-550 under ice-salt bath cooling condition, and stir rapidly, stirring for 1h. Under rapid stirring conditions, add 25ml of ethanol solution with a concentration of 0.2mol / L KOH, stir well, then add 70g of water, and add 1000g of KH-550 at a uniform speed for 5 hours. After reacting for 12 hours under low-speed stirring condition, the residual water and alcohol compounds were distilled off under reduced pressure to obtain silicon-containing monomers with relatively large molecular weights.

[0065] Add 100g of the silicon-containing monomer prepared above and 150g of modified polyether (TPEG) with a molecular weight of 2400 into the reaction vessel, add 200g of distilled water, stir and heat up to 65-80°C, add 3.0g of initiator sodium persulfate, and start the process after stirring evenly 55.0 g of acrylic acid and 40 g of a 5 wt % solution of chain tr...

Embodiment 2

[0067] Add 200g of dry maleic anhydride into the three-necked flask, slowly and uniformly add 250g of silane coupling agent KH-550 under ice-salt bath cooling condition, and stir rapidly, stirring for 1h. Under the condition of rapid stirring, add 20ml of ethanol solution with a concentration of 0.2mol / L KOH, stir well, then add 70g of water, and add 500g of KH-550 at a uniform speed for 3 hours. The reaction was carried out for 6 hours under low-speed stirring, and the residual water and alcohol compounds were removed by distillation under reduced pressure to obtain a silicon-containing monomer with a relatively small molecular weight.

[0068] Add 100g of the silicon-containing monomer prepared above and 200g of modified polyether (TPEG) with a molecular weight of 2400 into the reaction vessel, add 200g of distilled water, stir and heat up to 65-80°C, add 3.0g of initiator sodium persulfate, and start the process after stirring evenly 50.0 g of acrylic acid and 35 g of a 5 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com