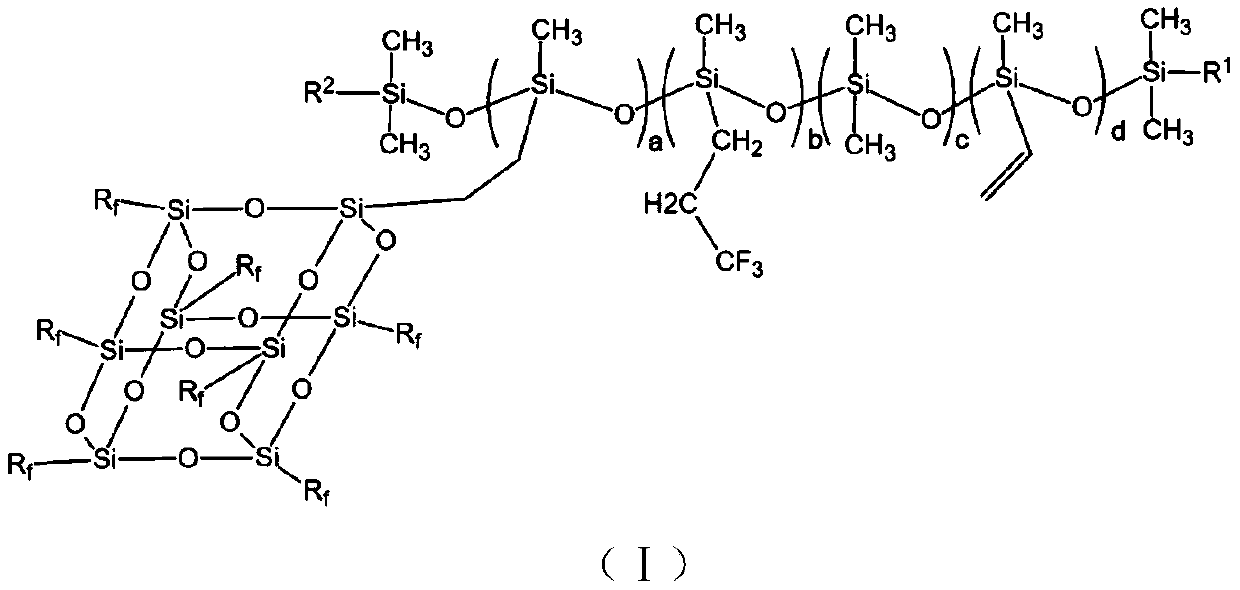

High-strength copolymerized fluorinated silicone rubber composition and preparation method thereof

A fluorosilicone rubber, high-strength technology, applied in the field of preparation of high-strength copolymerized fluorosilicone rubber compositions, can solve the problems of low mechanical strength and insufficient heat resistance of copolymerized fluorosilicone rubber, and achieve improved mechanical strength, increased quantity, tightly wound effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

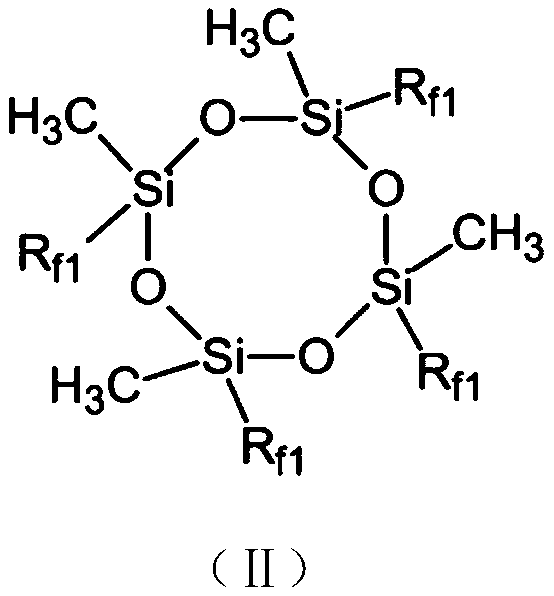

Embodiment approach

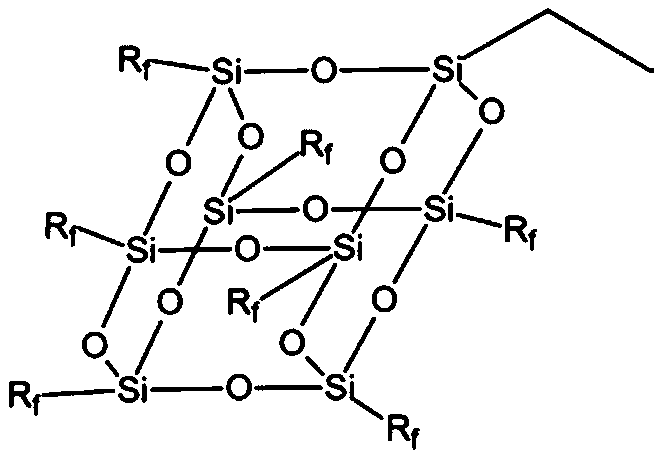

[0042] Preparation of monofunctional hepta(trifluoropropyl) POSS

[0043] Refer to the method of the journal document "Nanostructures and Surface Dewettability of EpoxyThermosets Containing Hepta (3,3,3-trifluoropropyl) Polyhedral Oligomeric Silsesquioxane-Capped Poly (ethylene oxide)".

[0044] (1) Hepta(trifluoropropyl)hydrogen POSS

[0045] Add 10g of hepta(trifluoropropyl)silsesquioxane trisilanol sodium salt and 1.3ml of triethylamine into a 500ml container, add 200ml of anhydrous tetrahydrofuran, stir, place in an ice-water bath, add dropwise 1.43g of trichloro The mixed solution of silane and 20ml of anhydrous tetrahydrofuran was stirred for 4 hours, heated to room temperature, continued to react for 20 hours, filtered, and the filtrate was rotary evaporated to remove the solvent to obtain a white solid powder, which was dried in an oven at 40°C to obtain the product.

[0046] FT-IR test shows that the product is at 2160cm -1 There is a moderate intensity sharp absorp...

Embodiment 1~6

[0059] High-strength copolymerized fluorosilicone rubber composition, including the following components:

[0060] A) Copolyfluorosilicone raw rubber

[0061] A-1) copolyfluorosilicone raw rubber 1;

[0062] A-2) copolyfluorosilicone raw rubber 2;

[0063] A-3) copolyfluorosilicone raw rubber 3;

[0064] A-4) copolyfluorosilicone raw rubber 4;

[0065] B) Fumed silica

[0066] B-1)cabot M-5;

[0067] B-2) evonik degussa A200;

[0068] C) Viscosity (25°C) 110mPa·s hydroxyfluorosilicone oil

[0069] D) High vinyl fluorosilicone oil

[0070] D-1) Viscosity (25°C) 430mPa·s, vinyl mass percentage 7.2%;

[0071]D-2) Viscosity (25°C) 690mPa·s, vinyl mass percentage 6.6%;

[0072] E) Double pentasulfurizing agent

[0073] F) Pigment

[0074] F-1) iron red;

[0075] F-2) ultramarine blue;

[0076] F-3) rutile titanium dioxide;

[0077] The formulations of the high-strength copolymerized fluorosilicone rubber compositions of Examples 1-6 are shown in Table 1.

[0078] Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com