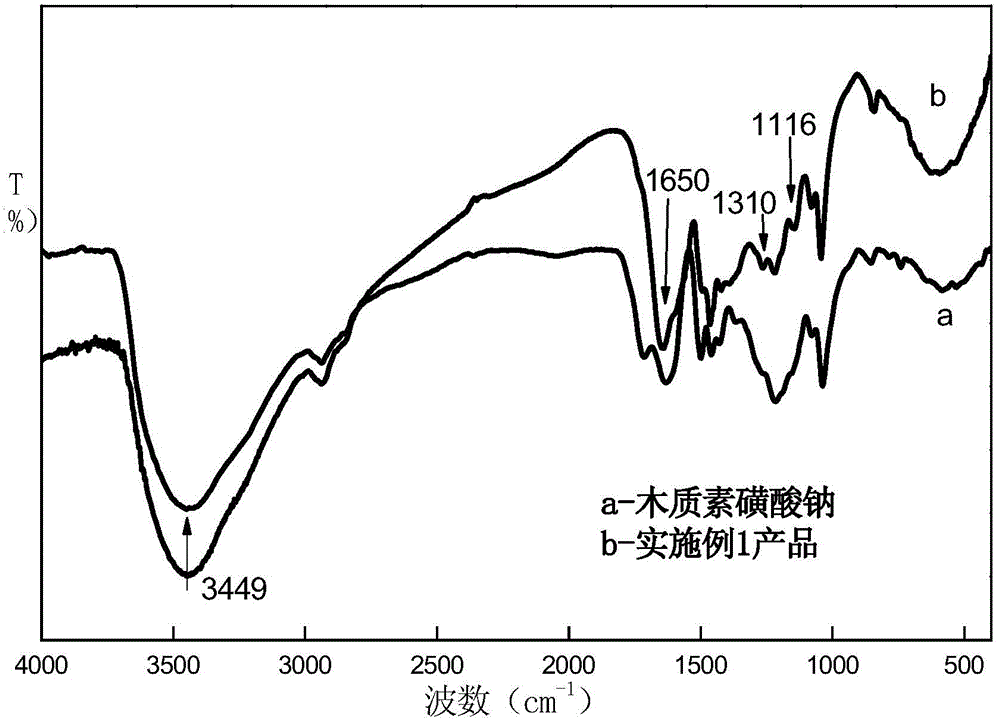

Modified sodium lignin sulfonate chelating agent containing phosphonic acid group and preparation method thereof

A technology of sodium lignosulfonate and chelating agent, applied in the field of chelating agent, can solve problems such as less variety of chelating ability, and achieve the effects of excellent performance-price ratio, improved reactivity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

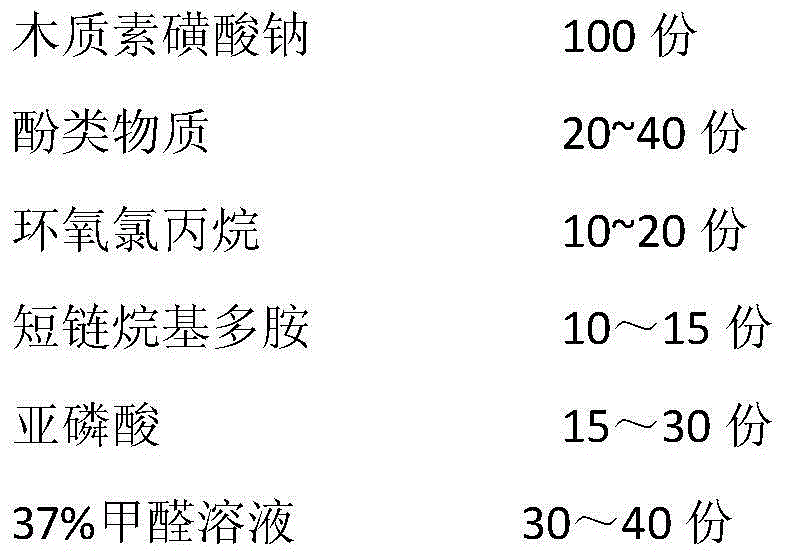

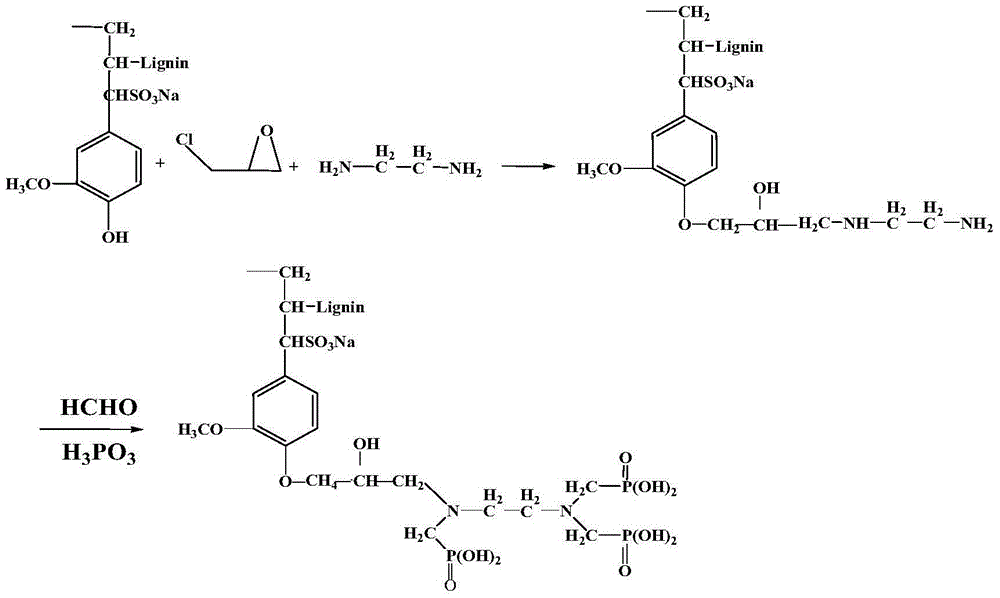

Embodiment 1

[0028] Get 100g of sodium lignosulfonate powder from acid pulping waste liquor and add it into water, stir and dissolve to make an aqueous solution with a mass concentration of 30%, add 40g of phenol, adjust the pH value of the system to 9 with 10mol / L NaOH, and place In the frequency conversion microwave reactor, adjust the power to 300W, raise the temperature to 95°C and react for 0.5h; take the above reaction solution out of the microwave reactor, add 15g of epichlorohydrin and 10g of ethylenediamine, and heat it in a normal pressure water bath to adjust the temperature To 80 ° C, stirring the reaction for 1h. Then the system is cooled to 30° C. and then 30 g of phosphorous acid crystals are added, stirred and mixed evenly; after the temperature of the system is lowered to 30° C., 40 g of formaldehyde solution with a mass concentration of 37% is added dropwise (controlling the dripping within 30 minutes), and then the temperature is raised to 80 °C for 2 hours, and the modi...

Embodiment 2

[0031] Take 100 g of sodium lignosulfonate powder from acid pulping waste liquid and add it to water, stir and dissolve to make an aqueous solution with a mass concentration of 35%, add 30 g of resorcinol, and adjust the pH value of the system to 10 with 10 mol / L NaOH Finally, put it in a frequency conversion microwave reactor, adjust the power to 1200W, and heat up to 90°C for 0.5h; take the above reaction solution out of the microwave reactor, add 10g of epichlorohydrin and 12g of diethylenetriamine, and use a normal pressure water bath Heating, adjusting the temperature to 75 ° C, stirring the reaction for 2h. Then the system is cooled to 35°C and then 18g of phosphorous acid crystals are added, stirred and mixed evenly; after the temperature of the system is lowered to 35°C, 35g of formaldehyde solution with a mass concentration of 37% is added dropwise (controlling the dripping within 30min), and then the temperature is raised to 90 °C for 3 hours, and the modified sodium...

Embodiment 3

[0033]Take 100 g of sulfonated alkali lignin sodium salt powder from alkaline pulping waste liquid, add it to water, stir and dissolve to make an aqueous solution with a mass concentration of 30%, add 30 g of hydroquinone, and adjust the pH value of the system with 10 mol / L NaOH After the temperature is 8, it is placed in a frequency conversion microwave reactor, the power is adjusted to 600W, and the temperature is raised to 100 ° C for 1 hour; the above reaction solution is taken out from the microwave reactor, and 20 g of epichlorohydrin and 15 g of 1,3-propylenediamine are added. Heating in a normal pressure water bath, adjusting the temperature to 70°C, and stirring for 1.5h. Then the system is cooled to 40°C and then 15g of phosphorous acid crystals are added, stirred and mixed evenly; after the temperature of the system is lowered to 40°C, 30g of formaldehyde solution with a mass concentration of 37% is added dropwise (controlling the dripping within 30min), and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com