Degradable polymer composite material and preparation method thereof

A technology for degrading polymers and composite materials, applied in the field of degradable polymer composite materials and their preparation, can solve the problems of environmental pollution, polymer composite materials cannot be degraded, etc., achieve good thermal stability, reduce emissions, and mechanical properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

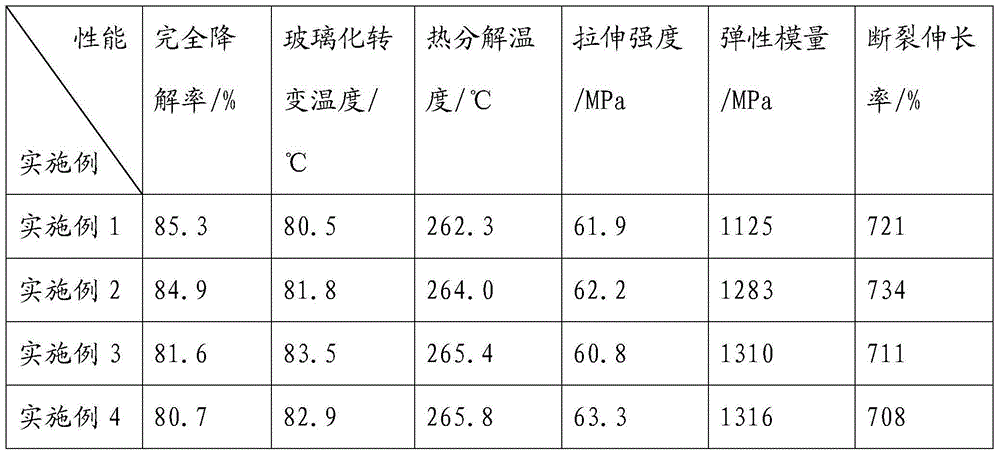

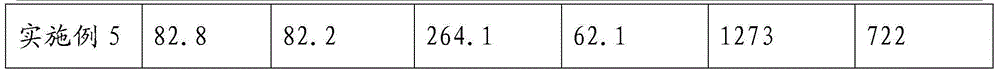

Examples

Embodiment 1

[0026] Composite material preparation method: first, get 50kg polypropylene carbonate and be mixed with the chloroform solution of mass fraction 5%, 10kg terminal hydroxyl branched polystyrene, be mixed with the chloroform solution of mass fraction 10%; Then two The solution is mixed, and the ultrasonic wave is used to promote its uniform mixing, and the time is 10 to 20 minutes. Then, after volatilizing and recovering most of the solvent at normal temperature and low pressure, put it in a vacuum oven, and dry it at 40-50°C to constant weight; then add the obtained mixture and 15kg of propylene-propylene glycol copolymer to the mixing equipment, at 180-200 Melting and blending at ℃, the co-melt formed was dissolved in chloroform again to obtain a solution with a mass fraction of 10%, and finally, 25kg of polyhydroxybutyrate-co-hydroxycaproate was formulated into a mass fraction of 5 % chloroform solution, and ultrasonically mix with the above solution for 20-30 minutes; repeat...

Embodiment 2

[0028] Composite material preparation method: first, get 50kg polypropylene carbonate and be mixed with the chloroform solution of mass fraction 5%, 15kg terminal hydroxyl branched polystyrene, be mixed with the chloroform solution of mass fraction 10%; Then two The solution is mixed, and the ultrasonic wave is used to promote its uniform mixing, and the time is 10 to 20 minutes. Then, after volatilizing and recovering most of the solvent at normal temperature and low pressure, put it into a vacuum oven, and dry it at 40-50°C to constant weight; then add the obtained mixture and 20kg of propylene-propylene glycol copolymer to the mixing equipment, at 180-200 Melting and blending at ℃, the co-melt formed was dissolved in chloroform again to obtain a solution with a mass fraction of 10%, and finally, 15kg of polyhydroxybutyrate-co-hydroxycaproate was formulated into a mass fraction of 5 % chloroform solution, and ultrasonically mix with the above solution for 20-30 minutes; repe...

Embodiment 3

[0030] Composite material preparation method: first, get 40kg polypropylene carbonate and be mixed with the chloroform solution of 5% mass fraction, 20kg terminal hydroxyl branched polystyrene, be mixed with the chloroform solution of 10% mass fraction; The solution is mixed according to the press, and the ultrasonic wave is used to promote the uniform mixing, and the time is 10 to 20 minutes. Then, after volatilizing and recovering most of the solvent at normal temperature and low pressure, put it into a vacuum oven, and dry it at 40-50°C to constant weight; then add the obtained mixture and 20kg of propylene-propylene glycol copolymer to the mixing equipment, at 180-200 Melting and blending at ℃, the co-melt formed was dissolved in chloroform again to obtain a solution with a mass fraction of 10%, and finally, 20kg of polyhydroxybutyrate-co-hydroxycaproate was formulated into a mass fraction of 5 % chloroform solution, and ultrasonically mix with the above solution for 20-30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com