Energy-saving environment-friendly asphalt and preparation method thereof

An energy saving, environmental protection and preparation technology, which is applied in building thermal insulation materials, building components, climate change adaptation, etc., can solve problems such as aggravating environmental damage, non-renewable resource consumption, white garbage cannot be recycled, and damage to the road performance of mixed materials. , to reduce friction, increase viscosity and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

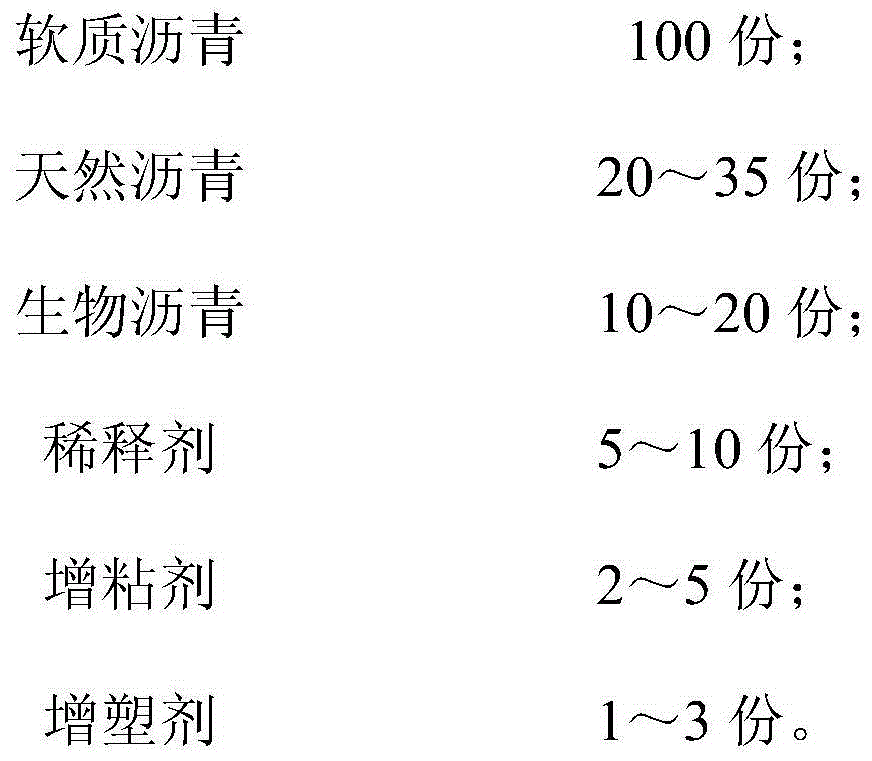

[0045] An energy-saving and environment-friendly asphalt, comprising the following raw materials in parts by weight: 100 parts of 130# matrix asphalt, 20 parts of rock asphalt, 15 parts of biological asphalt, 5 parts of diluent, and the diluent is vegetable oil, 3 parts of polyamide resin As a tackifier, 2 parts powdered cellulose as a plasticizer.

[0046] The environment-friendly asphalt of the present embodiment is prepared according to the following steps:

[0047] 1) In parts by weight, 15 parts of bio-asphalt, 3 parts of tackifier and 2 parts of plasticizer were mixed in sequence and stirred evenly to obtain mixture A;

[0048] 2) Take 100 parts of 130# base asphalt and heat it up to 140°C, heat it to a molten state, then pour the molten 130# base asphalt into the stirring equipment with a rotation speed of 300-500r / min;

[0049] 3) Add 5 parts of diluent to the 130# base asphalt in the mixing equipment, and fully stir to obtain the mixture B;

[0050] 4) Add 20 parts ...

Embodiment 2

[0055] A kind of energy-saving and environment-friendly asphalt, in parts by weight, comprises the following composition raw materials: 100 parts of 110# matrix asphalt, 25 parts of Trinidad (TLA) lake asphalt, 10 parts of biological asphalt, 6 parts of waste lubricating oil As diluent, 3 parts tackifier, 3 parts plasticizer.

[0056] Among them, the tackifier adopts a mixture of 1 part of epoxy resin and 2 parts of polyurethane, and the plasticizer adopts 0.5 part of waste rubber powder, 1 part of waste plastic, 0.5 part of powdered cellulose, 0.5 part of powdered styrene-butadiene rubber SBR and 0.5 part of powder A blend of thermoplastic styrene-butadiene rubber SBS.

[0057] The environment-friendly asphalt of the present embodiment is prepared according to the following steps:

[0058] 1) In parts by weight, 10 parts of bio-asphalt, 3 parts of tackifier and 3 parts of plasticizer were mixed in sequence and stirred evenly to obtain mixture A;

[0059] 2) Take 100 parts o...

Embodiment 3

[0066] A kind of energy-saving and environment-friendly asphalt, in parts by weight, comprises the following composition raw materials: 100 parts of 160# matrix asphalt, 30 parts of Trinidad (TLA) lake asphalt, 20 parts of biological asphalt, 9 parts of diluent, 5 parts 1 part tackifier, 3 parts waste plastic as plasticizer.

[0067] Wherein the diluent adopts the mixture of 8 parts of waste oil and 1 part of turpentine, and the tackifier adopts the mixture of 2 parts of polyurethane and 3 parts of petroleum resin.

[0068] The environment-friendly asphalt of the present embodiment is prepared according to the following steps:

[0069] 1) In parts by weight, 20 parts of bio-asphalt, 5 parts of tackifier and 3 parts of plasticizer were mixed in sequence and stirred evenly to obtain mixture A;

[0070] 2) Take 100 parts of 160# base asphalt and heat it up to 150°C, heat it to a molten state, then pour the molten 160# base asphalt into the stirring equipment with a rotation spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com