Lactobacillus paracasei and application thereof, fermentation product and preparation method thereof

A technology for fermented products and Lactobacillus, which is applied to Lactobacillus paracasei and its application fields, can solve the problems of slow fermentation acid production, reduced production efficiency, prolonged fermentation time, etc., and achieves the effects of strong acid production capacity and improved vitality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In a fourth aspect, the present invention provides a method for preparing a fermented product, wherein the method includes: inoculating the above-mentioned Lactobacillus paracasei cells into the raw material to be fermented, and performing fermentation.

[0026] According to the present invention, the cells of Lactobacillus paracasei inoculated into the raw material to be fermented are live cells. However, those skilled in the art know that, in the process of bacterial cell culture, it is usually accompanied by the death of the bacterial cells, and the living cells do not mean that all the cells are live cells in the strict sense.

[0027] The present invention has no special limitation on the number of bacteria cells of Lactobacillus paracasei to be inoculated, and can be specifically adjusted according to different uses. Preferably, with the raw material to be fermented of 100mL or 100g as a benchmark, the inoculum of the thalline of described Lactobacillus paracasei ...

Embodiment 1

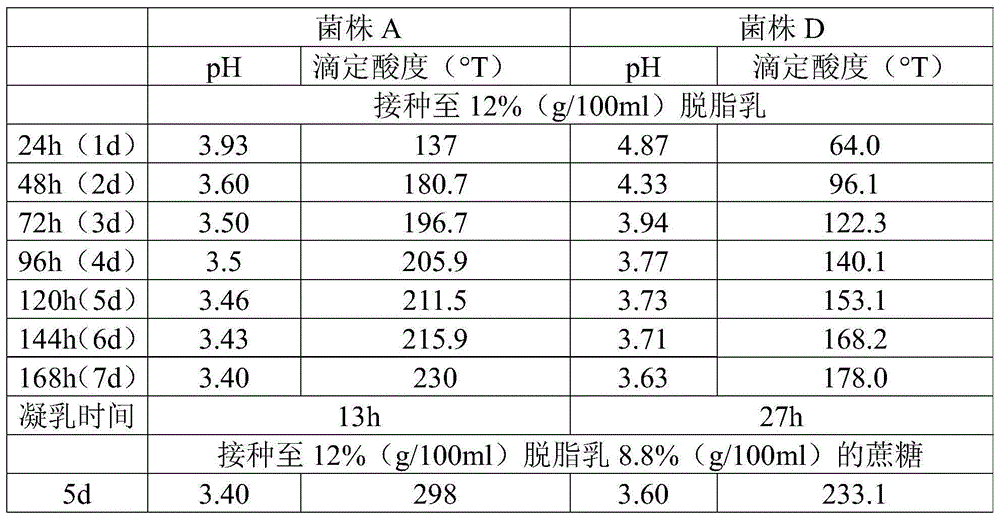

[0041] This embodiment is used to illustrate the fermentation performance of Lactobacillus paracasei provided by the present invention

[0042]The bacterial strain A activated overnight at 37°C was inoculated into 12% (g / 100ml) skim milk according to the inoculation amount of 1% by volume, and fermented continuously at 37°C for 7 days, and the pH and titrated acidity were measured every 24h; the milk curdling time of the bacterial strain A was recorded, every Each sample was repeated 3 times and the average value was taken. Results Table 1.

[0043] The strain A activated overnight at 37°C was inoculated into 12% (g / 100ml) skim milk plus 8.8% (g / 100ml) sucrose according to the inoculum size of 1% by volume, and fermented continuously at 37°C for 5 days, and the pH and titrated acidity were measured; Each sample was repeated 3 times and the average value was taken. Results Table 1.

Embodiment 2

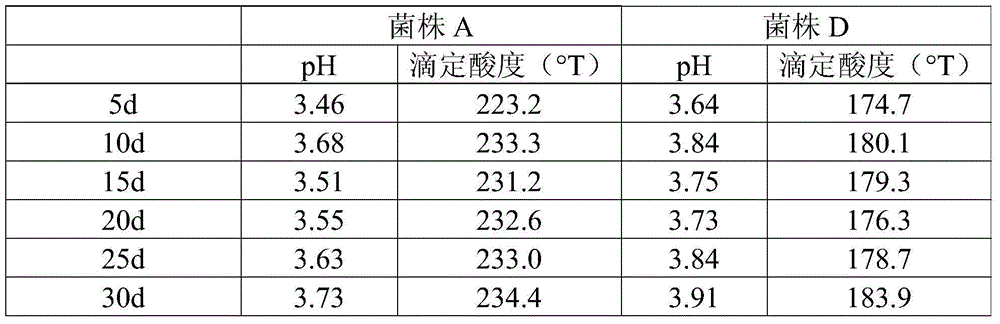

[0045] This embodiment is used to illustrate the storage performance of Lactobacillus paracasei provided by the present invention

[0046] The strain activated overnight at 37°C was inoculated into 12% (g / 100ml) skim milk at an inoculum volume of 1% by volume. After continuous fermentation at 37°C for 7 days, it was stored at 4°C for 30 days. pH and titrated acidity were measured every 5 days. 3 repetitions, averaged. Results Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com