Method for preparing copper-containing solution by dissolving waste copper

A copper solution and a technology for the solution are applied in the field of realizing the efficient dissolution of the above-mentioned copper-rich raw materials at normal temperature to prepare a copper-containing solution, which can solve the problems of high energy consumption and low copper dissolution rate, and achieve low energy consumption and copper dissolution. The effect of fast speed and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

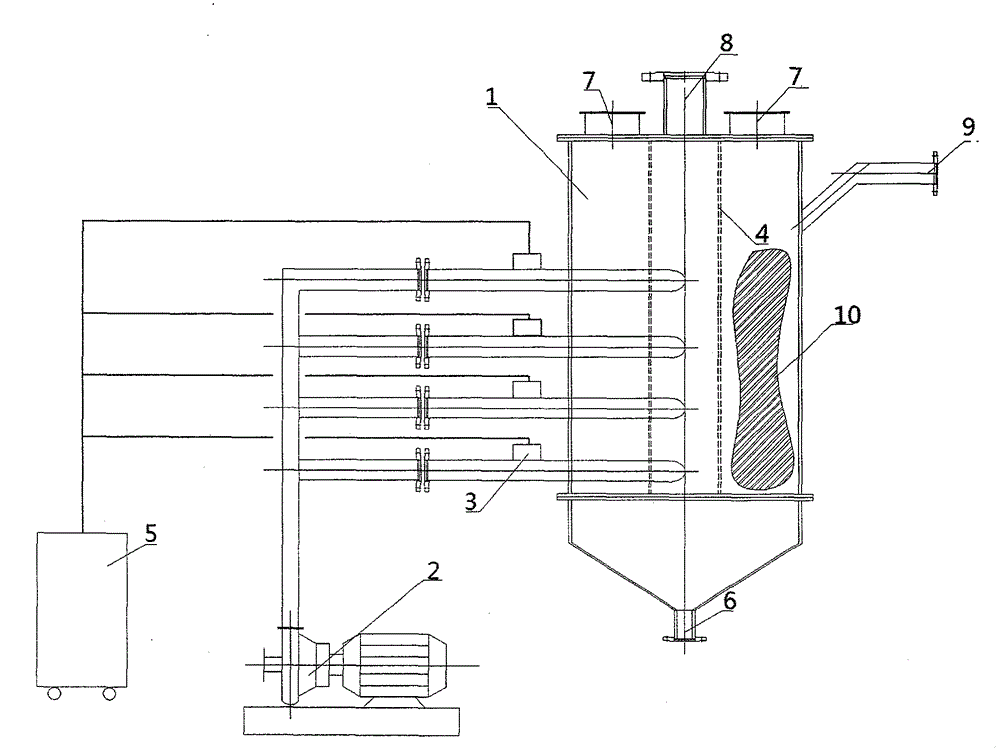

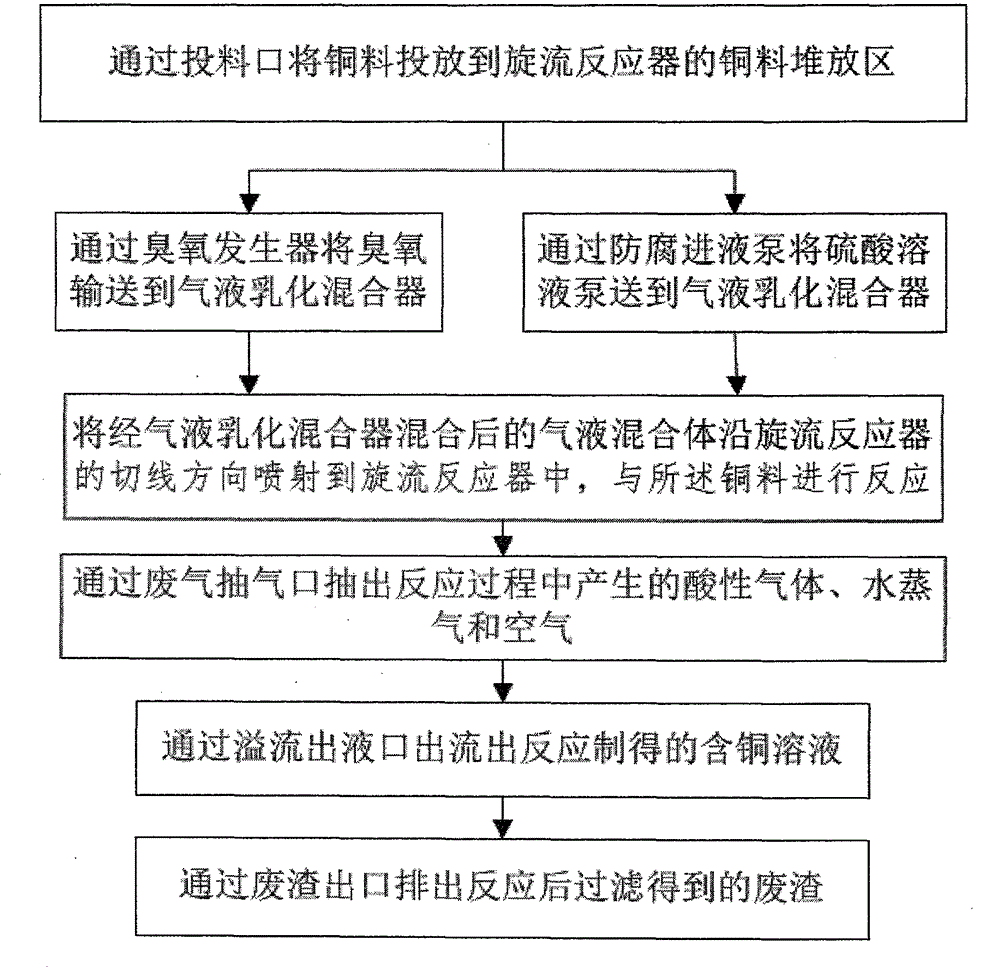

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the contents of the specific embodiments are not intended to limit the protection content of the present invention.

[0022] The invention relates to a method for preparing a copper-containing solution by dissolving waste copper, which is mainly used for making copper electrolyte solution, which is energy-saving, high-efficiency, corrosion-resistant, simple to operate, fast in oxidation speed, short in reaction time and less in exhaust gas emission. The method of dissolving copper has important meanings such as increasing the dissolution rate, reducing energy consumption and reducing production costs by dissolving at room temperature. It is a new method of dissolving copper with environmental protection, high efficiency, low consumption, low cost, and convenient operation and management.

[0023] Compared with the prior art, the method fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com