Bran finisher double-turned mass dampers, combined vibration reduction and isolation device and implementation method

A technology of tuning mass damping and tuning mass blocks, which is applied in the direction of instruments, mechanical equipment, springs/shock absorbers, etc., and can solve problems such as poor single vibration isolation efficiency, unstable vibration, and unfavorable long-term normal operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

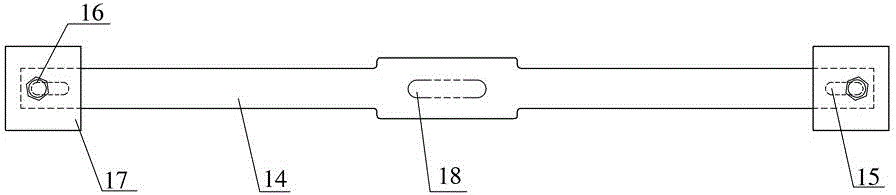

[0042] Embodiment 1: see figure 1 and figure 2 , a tuned mass damper for a bran threshing machine, comprising double cantilever beams 14 and tuning mass blocks 17, and the tuning mass blocks 17 are arranged at both ends of the double cantilever beams 14.

[0043] The two ends of the double cantilever beam 14 are respectively provided with waist-shaped holes 15 arranged along the length direction of the double cantilever beam; the tuning mass 17 is installed on the two free ends of the double cantilever beam 14 through bolts and nuts d, and the bolts pass through the tuning mass 17 and the waist shaped hole 15, and locked by a nut.

[0044] The double cantilever beam structure is fixed in the middle and cantilevered at both ends; the center line of the waist-shaped hole in the longitudinal direction coincides with the central axis of the double cantilever beam in the longitudinal direction.

Embodiment 2

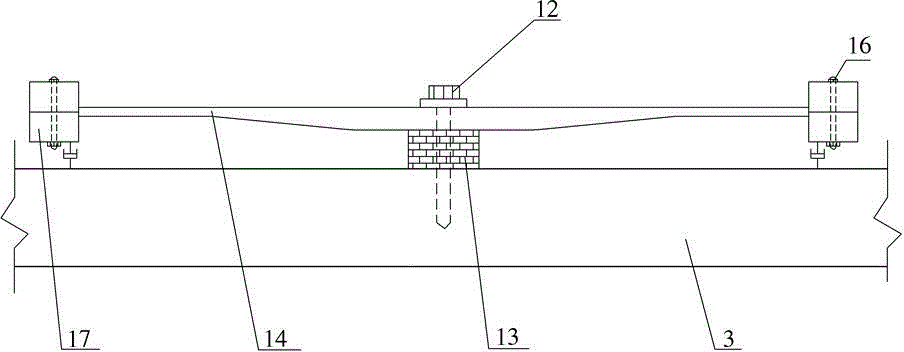

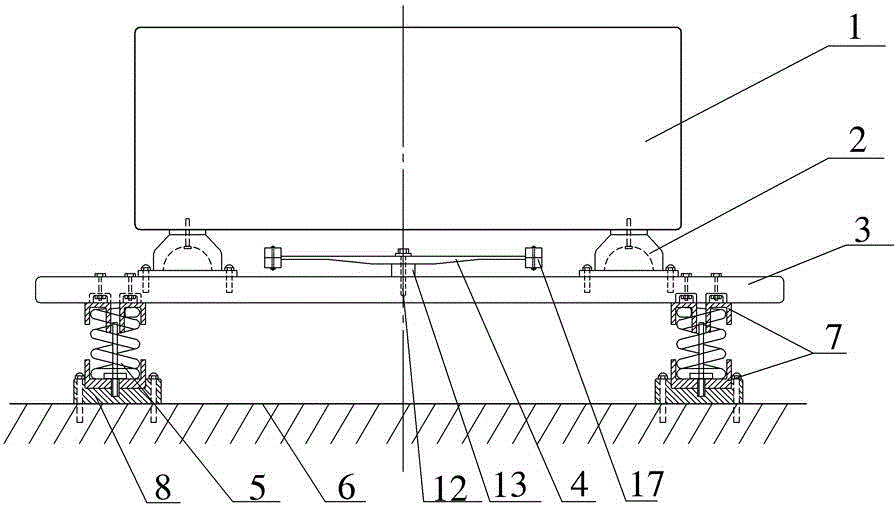

[0045] Example 2: see Figure 3 to Figure 6 , a compound vibration-reducing and isolating device for a bran-threshing machine containing the double-tuned mass damper of the above-mentioned bran-threshing machine also includes a vibration-isolation system, and the vibration-isolation system consists of a rubber vibration isolator, a vibration-isolation steel plate and a steel spring vibration isolator It consists of a rubber vibration isolator installed on the upper surface of the vibration isolation steel plate, a steel spring vibration isolator on the lower bottom surface, and the rubber vibration isolator is arranged at the four corners of the bottom plate of the bran beater; the double tuned mass damper is set It is arranged symmetrically along the center line of the vibration-isolation steel plate at both ends of the vibration-isolation steel plate. As an optimal solution, in order to facilitate the fine-tuning of the tuned mass damper and weaken the vertical torsional vib...

Embodiment 3

[0050] Embodiment 3: a method for realizing the composite vibration-reducing and isolating device of the bran beating machine in embodiment 2, comprising the following steps:

[0051] (1) Determine the vibration frequency f of the bran beating machine: first collect the basic operating parameters of the bran beating machine, and determine the mass of the bran beating machine m 1 and the rated speed r, and then convert the rated speed r to obtain the vibration frequency f, or use the vibration test method to analyze the frequency spectrum to obtain the vibration frequency f.

[0052] (2) Design the rubber vibration isolator of the vibration isolation system of the composite vibration reduction and isolation device of the bran threshing machine: first, determine the vibration isolation frequency ω of the rubber vibration isolator 橡胶 , and then, according to the mass of the bran beater m 1 and vibration isolation frequency ω 橡胶 Determine the number and stiffness k of rubber iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com