Testing method for durability of aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and detection methods, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of high energy consumption, high cost, low efficiency, etc., and achieves low equipment power consumption, low experimental equipment investment, and shortened experiments. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

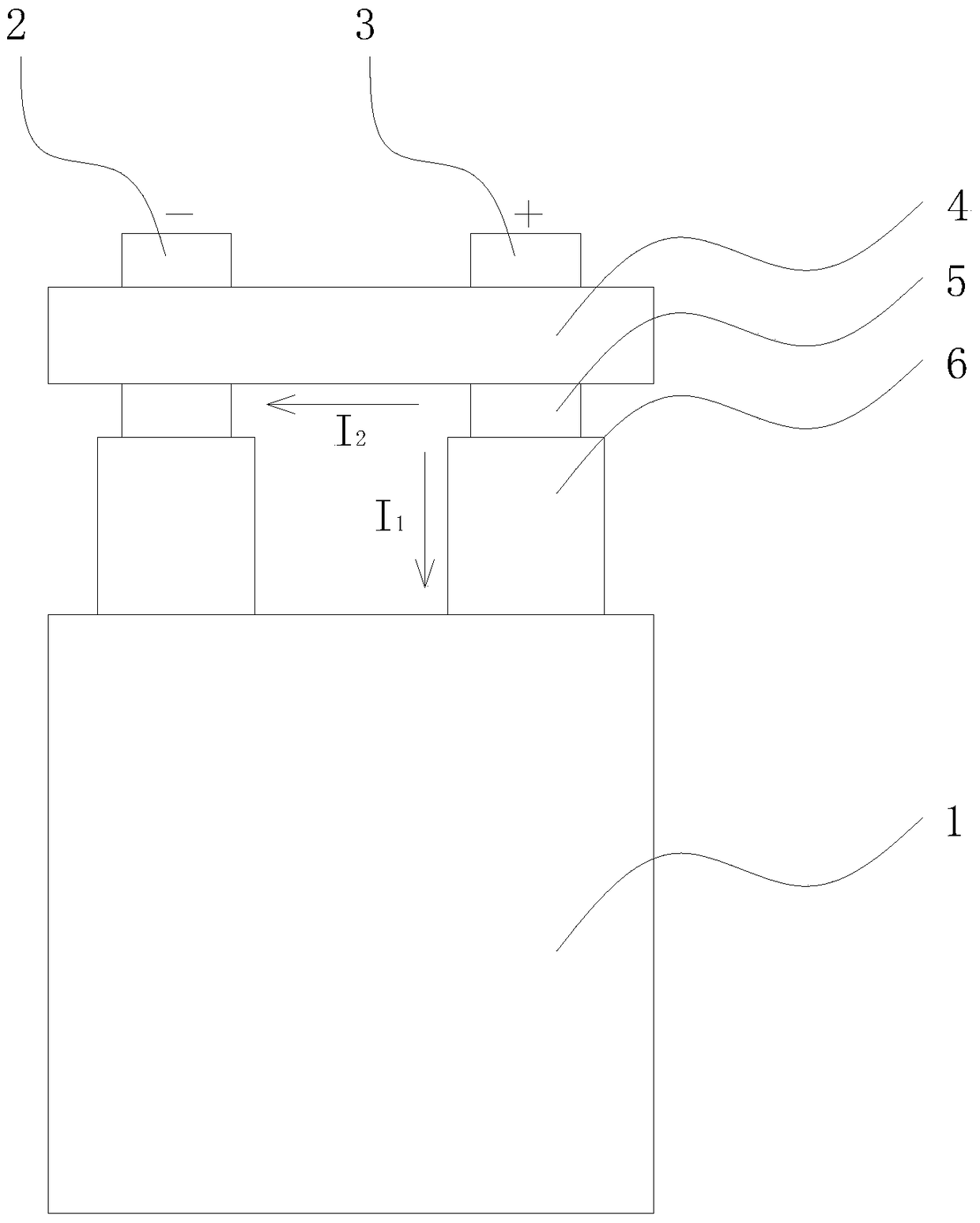

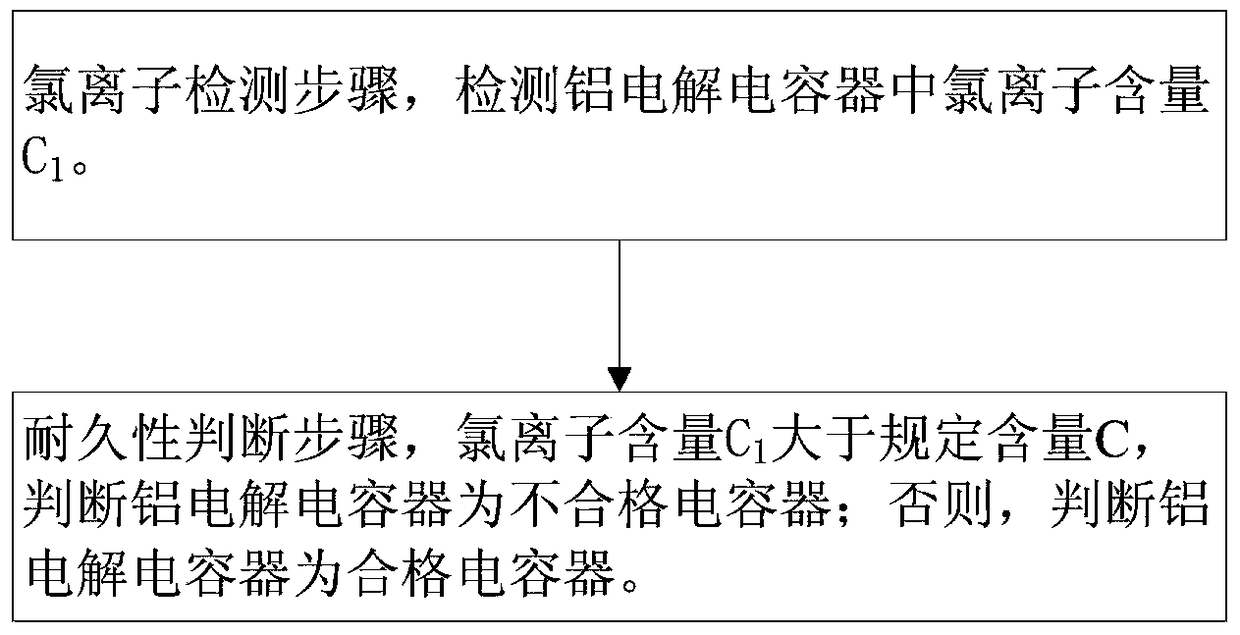

[0028] Embodiment one: if figure 2 As shown, the detection method of the durability of the aluminum electrolytic capacitor of the present invention, the detection method comprises: a chloride ion detection step and a durability judgment step, detecting the chloride ion content C in the aluminum electrolytic capacitor 1 ; Endurance judgment step, if the chloride ion content in the aluminum electrolytic capacitor C 1 If it is greater than the specified content C, it is judged that the aluminum electrolytic capacitor is an unqualified capacitor; otherwise, it is judged that the aluminum electrolytic capacitor is a qualified capacitor.

Embodiment 2

[0029] Embodiment two: if image 3 Shown, the detection method of aluminum electrolytic capacitor durability of the present invention, comprises the steps:

[0030] The step of weighing the aluminum electrolytic capacitor is a step of weighing the aluminum electrolytic capacitor before disassembly, and the mass of the aluminum electrolytic capacitor obtained by weighing is M.

[0031] In the chlorine ion extraction step, first soak the disassembled aluminum electrolytic capacitor in a certain amount of pure water, then vibrate and clean the aluminum electrolytic capacitor soaked in pure water, and then extract the chloride ions from the aluminum electrolytic capacitor , so that chloride ions dissolved in pure water.

[0032] Chloride ion detection step, detection of chloride ion content dissolved in pure water C 2 , according to the chloride ion content C 2 Calculate the chloride ion content C in the aluminum electrolytic capacitor 1 . Chloride ion content in aluminum ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com