Improvement method of backside metallization of igbt

A technology of backside metallization and backside metallization, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of Ag falling off, Ni and Ag adhesion decrease, etc., so as to avoid falling off, improve performance and yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

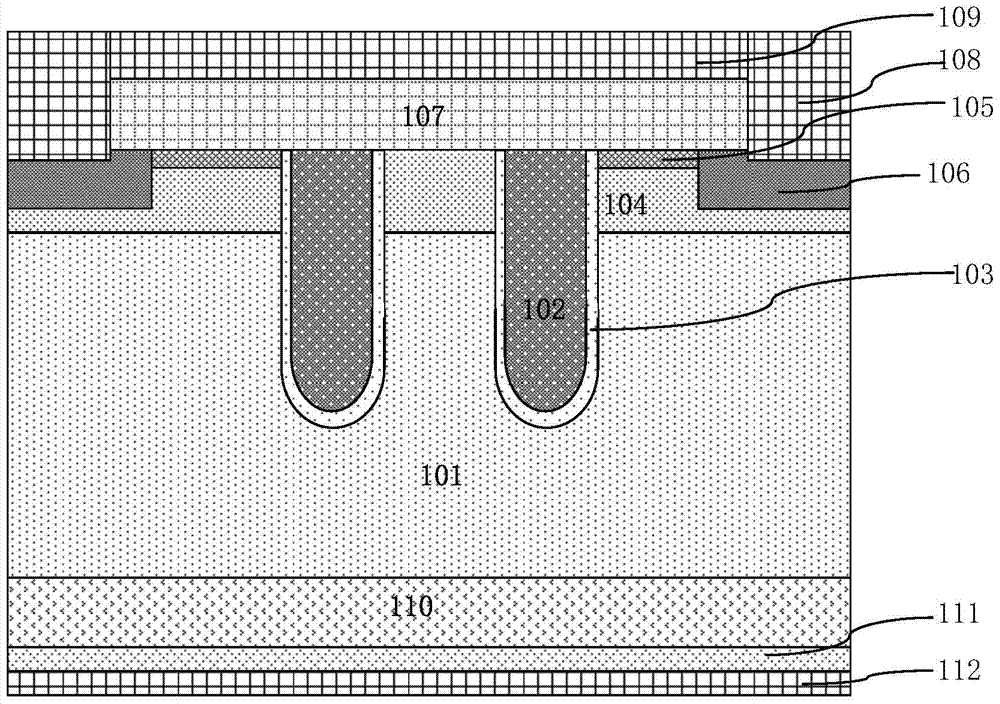

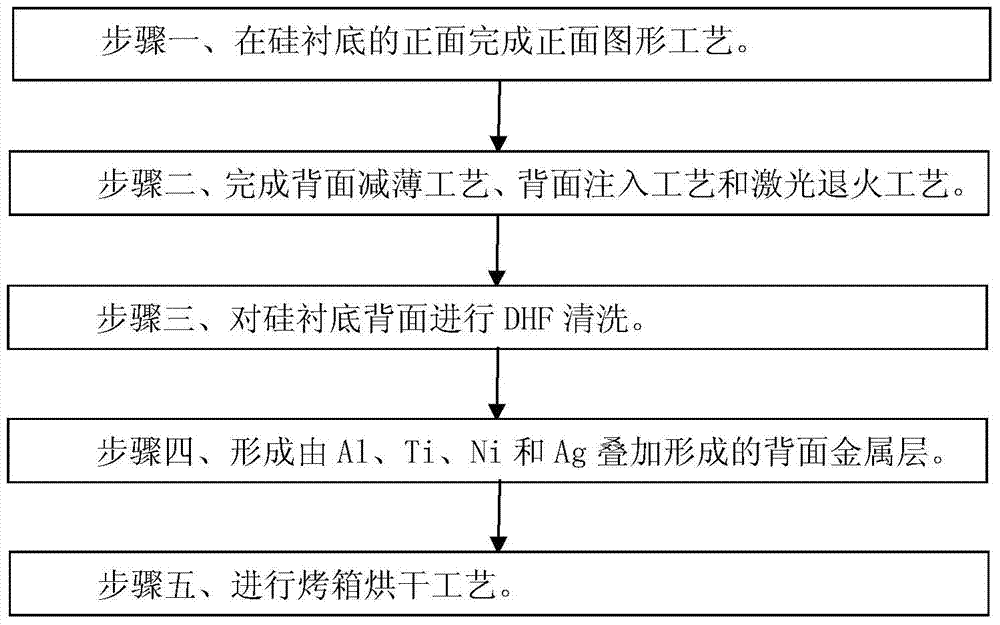

[0042] Such as figure 2 Shown is the flowchart of the method of the embodiment of the present invention; for the device structure of the IGBT formed by the method of the embodiment of the present invention, please refer to figure 1 As shown, the method for improving the backside metallization of the IGBT in the embodiment of the present invention includes the following steps:

[0043] Step 1: Complete the front pattern process on the front surface of the silicon substrate 101 .

[0044] Such as figure 1As shown, the front pattern process of the IGBT includes a cell area and a withstand voltage protection area, and the withstand voltage protection area surrounds the periphery of the cell area. The unit cell structure of the IGBT is formed in the cell region, and the unit structure of the IGBT includes:

[0045] The P well 104 is formed on the front side of the silicon substrate 101 .

[0046] A polysilicon gate 102 , a gate oxide layer 103 is isolated between the polysilic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com