Packaging convex point structure

A bump structure and layer structure technology, applied in electrical components, electric solid devices, circuits, etc., can solve problems such as bumps prone to microcracks, affect welding quality, and large internal stress, and improve long-term stability and reliability. performance, low cost, and the effect of reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

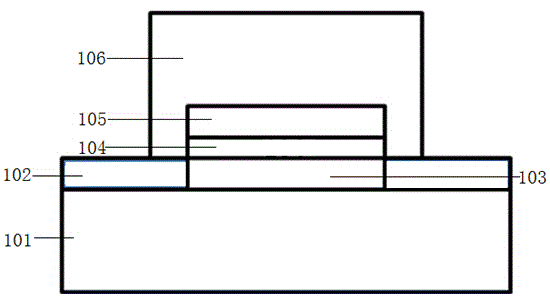

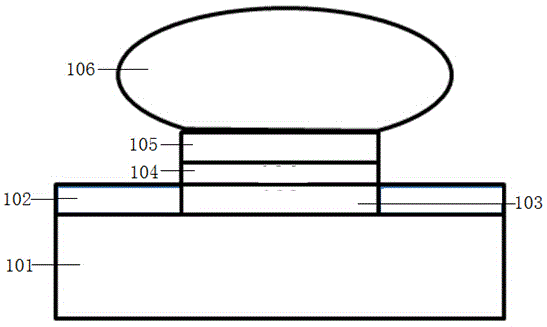

[0034] Such as figure 1 A bump structure for packaging shown includes a substrate layer 101 , a passivation layer 102 , a pad layer 103 , an adhesive layer 104 , a composite solder resist wetting layer 105 and a pre-solder layer 106 .

[0035] Both the passivation layer 102 and the pad layer 103 are located above the substrate layer 101 , and an opening is provided above the passivation layer 102 , and the pad layer 103 is embedded in the opening of the passivation layer 102 . The adhesive layer 104 , the composite solder resist wetting layer 105 , and the pre-solder layer 106 are sequentially arranged above the pad layer 103 from bottom to top.

[0036] The substrate layer 101 as the support of the entire bump structure should have good mechanical strength and good long-term stability. The material of the substrate layer is alumina ceramics, aluminum nitride ceramics, lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com