Waste processing method and waste incinerator

A treatment method and waste technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problem of expensive catalysts and achieve the effect of inhibiting the reaction of NOx formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

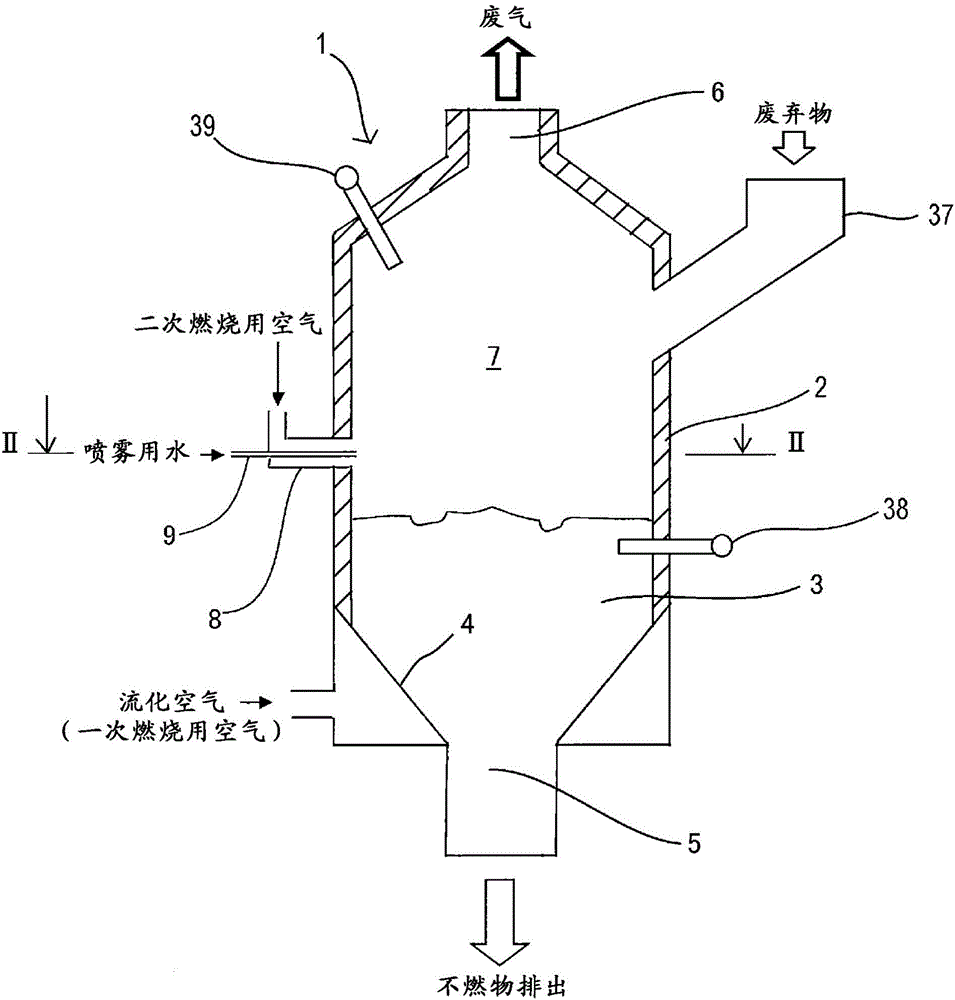

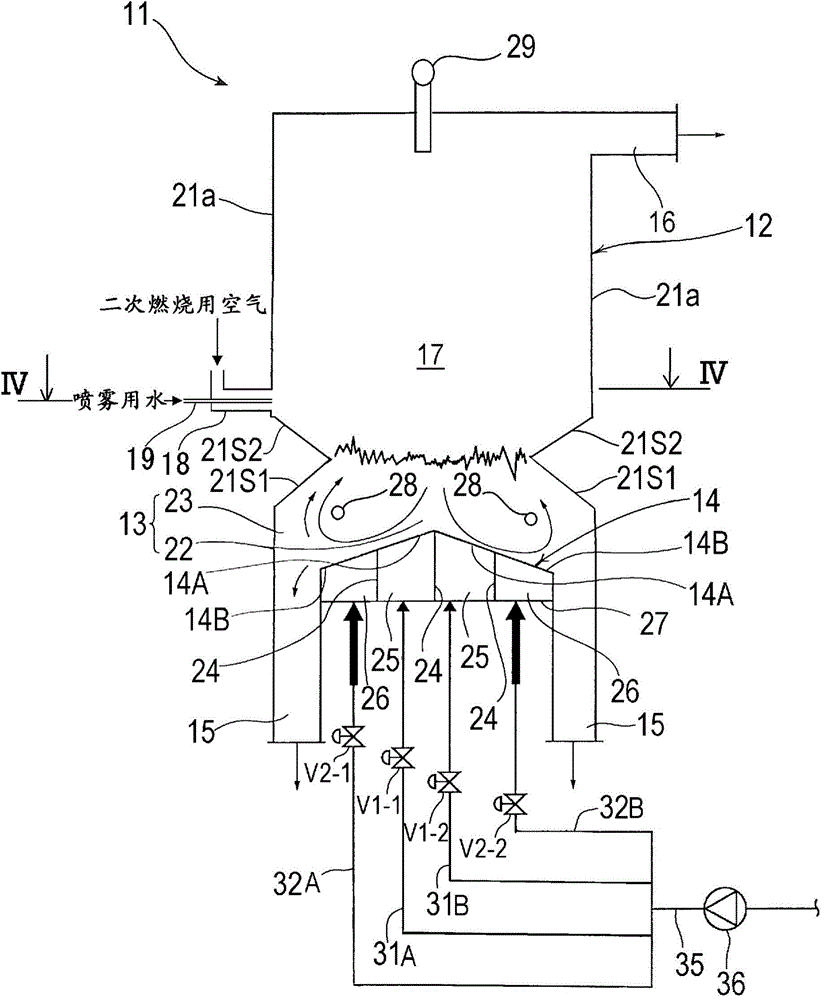

[0080] Below, refer to Figure 1 to Figure 15 Embodiments of the waste treatment method and the waste incinerator of the present invention will be described. exist Figure 1 to Figure 15 In , the same reference numerals are assigned to the same or equivalent constituent elements, and overlapping descriptions are omitted.

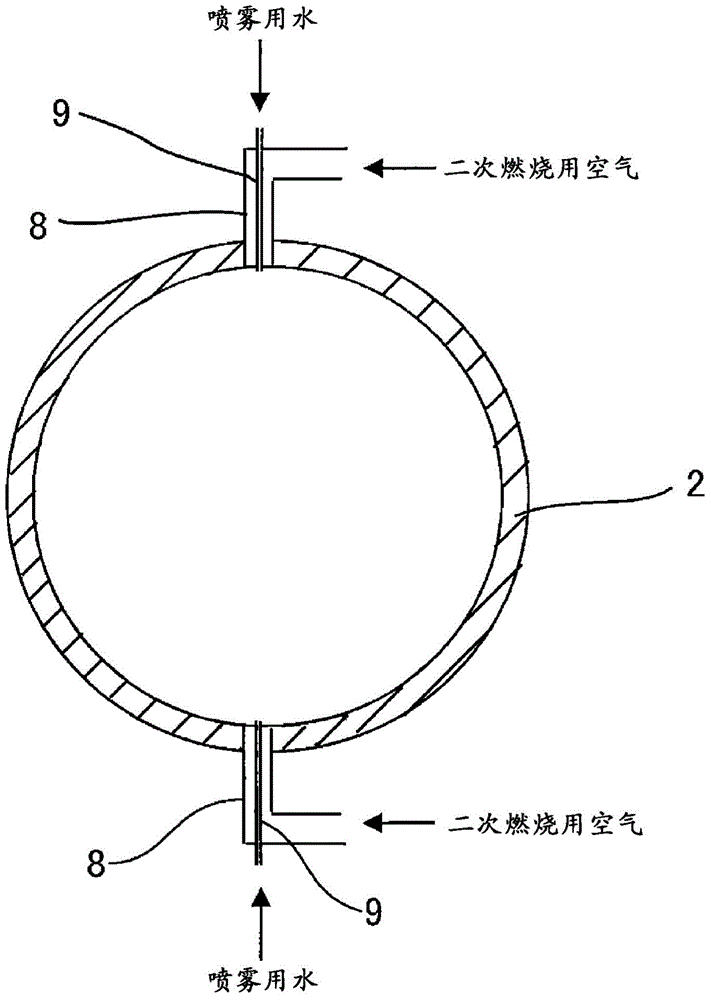

[0081] figure 1 It is a longitudinal sectional view showing a fluidized bed incinerator which is an embodiment of the waste incinerator of the present invention. figure 2 yes figure 1 Ⅱ-Ⅱ line sectional view. Such as figure 1 and figure 2 As shown, a fluidized bed incinerator 1 has a furnace body 2 for processing waste, a fluidized bed 3 for pyrolyzing and partially burning introduced waste, and a bed plate 4 for supporting the fluidized bed 3 . The fluidized bed 3 is typically a sand layer formed by accumulating sand such as silica sand, that is, a fluidizing medium. The space above the fluidized bed 3 inside the furnace body 2 becomes a free s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com