Preparation method of nutritious cumquat and fish scale jelly

A production method and technology of fish scale jelly, applied in the field of production of nutritional kumquat fish scale jelly, can solve the problems of cumbersome operation, destruction of nutrient components of fish scales, low product yield, etc., and achieve low raw material cost, crystal clear color and rich nutrition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

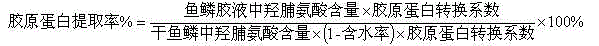

Method used

Image

Examples

Embodiment 1

[0022] (1) Thaw and clean fish scales

[0023] Thaw the fish scales naturally at room temperature, and wash them with water after rehydration;

[0024] (2), fish scale pretreatment

[0025] Take 200g of washed fish scales and rub them with 2g of salt and 20g of white vinegar for 10 minutes;

[0026] (3), enzymatic treatment

[0027] Add 200g of pretreated fish scales in step (2) into 400g of distilled water, then add 1g of neutral protease, carry out enzymatic hydrolysis in a water bath at 45°C for 5 hours, then inactivate the enzyme in a water bath at 90°C for 8 minutes, wash with distilled water twice, After draining the water, add 400g of distilled water, then add 1g of papain, carry out enzymatic hydrolysis in a water bath at 65°C for 3 hours, then inactivate the enzyme in a water bath at 90°C for 8 minutes, wash twice with distilled water, and drain;

[0028] (4), boiled gelatin

[0029] Put all the fish scales obtained after enzymatic hydrolysis in step (3) into 800g...

Embodiment 2

[0034] (1) Thaw and clean fish scales

[0035] Thaw the fish scales naturally at room temperature, and wash them with water after rehydration;

[0036] (2), fish scale pretreatment

[0037] Rub 200g of cleaned fish scales with 10g of salt and 4g of white vinegar for 20 minutes;

[0038] (3), enzymatic treatment

[0039] Add 200g of pretreated fish scales in step (2) into 600g of distilled water, then add 3g of neutral protease, carry out enzymatic hydrolysis in a water bath at 50°C for 3 hours, then inactivate the enzyme in a water bath at 90°C for 10 minutes, wash with distilled water 3 times, After draining the water, add 600g of distilled water, then add 3g of papain, carry out enzymatic hydrolysis in a water bath at 65°C for 3 hours, then inactivate the enzyme in a water bath at 90°C for 10 minutes, wash with distilled water for 3 times, and drain;

[0040] (4), boiled gelatin

[0041] Put all the fish scales obtained after enzymatic hydrolysis in step (3) into 1200 g ...

Embodiment 3

[0046] (1) Thaw and clean fish scales

[0047] Thaw the fish scales naturally at room temperature, and wash them with water after rehydration;

[0048] (2), fish scale pretreatment

[0049] Rub 200g of washed fish scales with 4g of salt and 10g of white vinegar for 15 minutes;

[0050] (3), enzymatic treatment

[0051] Add 200g of pretreated fish scales in step (2) into 500g of distilled water, the mass ratio of the fish scales to distilled water is 1:2.5, then add 2g of neutral protease, carry out enzymatic hydrolysis in a water bath at 47°C for 4 hours, and then in 90 Inactivate the enzyme in a water bath at ℃ for 9 minutes, wash with distilled water for 3 times, drain the water, add 500 g of distilled water, then add 2 g of papain, perform enzymatic hydrolysis at 60 °C for 4 h, then inactivate the enzyme in a water bath at 90 °C for 9 min, use Rinse with distilled water 3 times and drain;

[0052] (4), boiled gelatin

[0053] Put all the fish scales obtained after enzyma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com