Regeneration method for dehydrogenation catalyst

A dehydrogenation catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of difficult recovery of active centers and increased sintering of active centers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

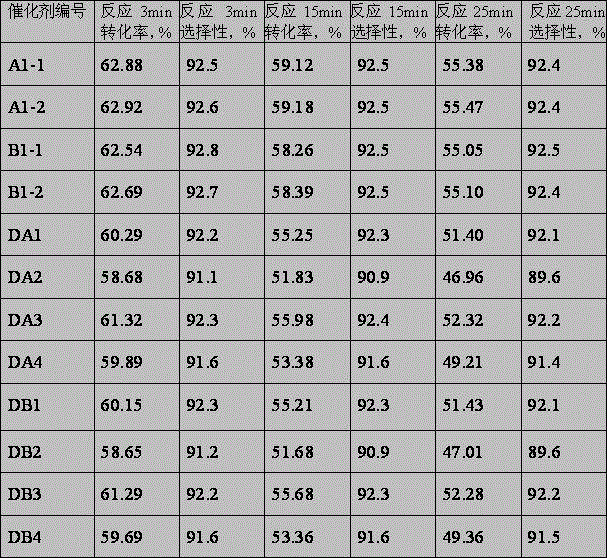

Examples

Embodiment 1

[0022] (1) Carrier preparation

[0023] Weigh 66.0g of pseudo-boehmite and 2.64g of bentonite to make a small spherical carrier through thorough mixing and kneading. The wet catalyst was dried in the air overnight, and dried at 120°C for 4 hours, and the dried sample was placed in a high-temperature furnace, raised to 600°C, and roasted at a constant temperature for 4 hours. prepared as a carrier;

[0024] (2) Formulated to 18.0% (weight concentration) Cr(NO 3 ) 3 aqueous solution;

[0025] (3) Prepare 3.86% (weight concentration) of KNO 3 aqueous solution;

[0026] (4) Take 86.80g of Cr(NO 3 ) 3 Aqueous solution, step (1) Immerse with the prepared carrier for 40 minutes, then dry at 120°C for 3 hours, and roast at a constant temperature of 580°C for 6 hours;

[0027] (5) Take 21.84g of KNO prepared in step (3) 3 Catalyst A was prepared by immersing in aqueous solution for 40 minutes, drying at 120°C for 3 hours, and roasting at 650°C for 4 hours.

Embodiment 2

[0029] (1) Prepare 3.86% (weight concentration) of KNO 3 aqueous solution.

[0030] (2) Formulated to 18.0% (weight concentration) Cr(NO 3 ) 3 aqueous solution.

[0031] (3) Combine 66.00g of pseudoboehmite, 2.64g of bentonite and 21.84g of KNO prepared in step (1) 3 The aqueous solution is fully mixed, kneaded, made into a plastic body and extruded into small balls. Then, it was dried at 120°C for 3 hours, and the dried sample was placed in a high-temperature furnace, and fired at a constant temperature of 580°C for 4 hours. Made of alumina carrier containing additives.

[0032] (4) Take 86.80g of Cr(NO 3 ) 3 The aqueous solution was used to impregnate the carrier prepared in step (4) for 40 minutes, then dried at 120°C for 3 hours, and then calcined at 650°C for 6 hours to prepare catalyst B.

Embodiment 3

[0034] The catalyst prepared in Example 1 is used in isobutane dehydrogenation to produce isobutene, dehydrogenation reaction conditions: reaction temperature 600°C, reaction space velocity 1000h -1 , the reaction pressure is normal pressure, the reaction time is 25min, and the deactivated catalyst A1 is obtained.

[0035] The catalyst prepared in Example 2 is used in isobutane dehydrogenation to produce isobutene, dehydrogenation reaction conditions: reaction temperature 600°C, reaction space velocity 1000h -1 , the reaction pressure is normal pressure, the reaction time is 25min, and the deactivated catalyst B1 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com