Method for preparing graphene

A graphene and calcination technology, applied in the field of carbon materials, can solve the problems of uncontrollable three-dimensional structure and limit the application of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a kind of preparation method of graphene, comprises the following steps:

[0033] A) carrying out a hydrothermal reaction in water with a surfactant, a carbon source and a metal catalyst to obtain an intermediate with a three-dimensional nanostructure;

[0034] B) calcining the intermediate with a three-dimensional nanostructure obtained in step A) under a protective gas atmosphere to obtain graphene.

[0035] The preparation method provided by the invention can control the three-dimensional structure of graphene, thereby realizing the controllable preparation of graphene.

[0036] In the present invention, a surfactant, a carbon source and a metal catalyst are subjected to a hydrothermal reaction in water to obtain an intermediate having a three-dimensional nanostructure. In the present invention, the surfactant, a carbon source and a metal catalyst are preferably mixed with water to obtain a mixed solution, and then The mixed solution is subjec...

Embodiment 1

[0048] Mix 20g of nickel acetate, 10g of glucose, 1g of sodium lauryl sulfate with 150ml of water, adjust the pH of the solution to 10.5 with ammonia water with a mass concentration of 25%, and conduct a hydrothermal reaction at 180°C for 24 hours to form a petal-shaped intermediate;

[0049] Then the intermediate was calcined at 850°C for 5 hours under a nitrogen atmosphere, and the heating rate was 5°C / min. The calcined product was washed with hydrochloric acid with a concentration of 1mol / L, filtered, and dried at 120°C to obtain graphene.

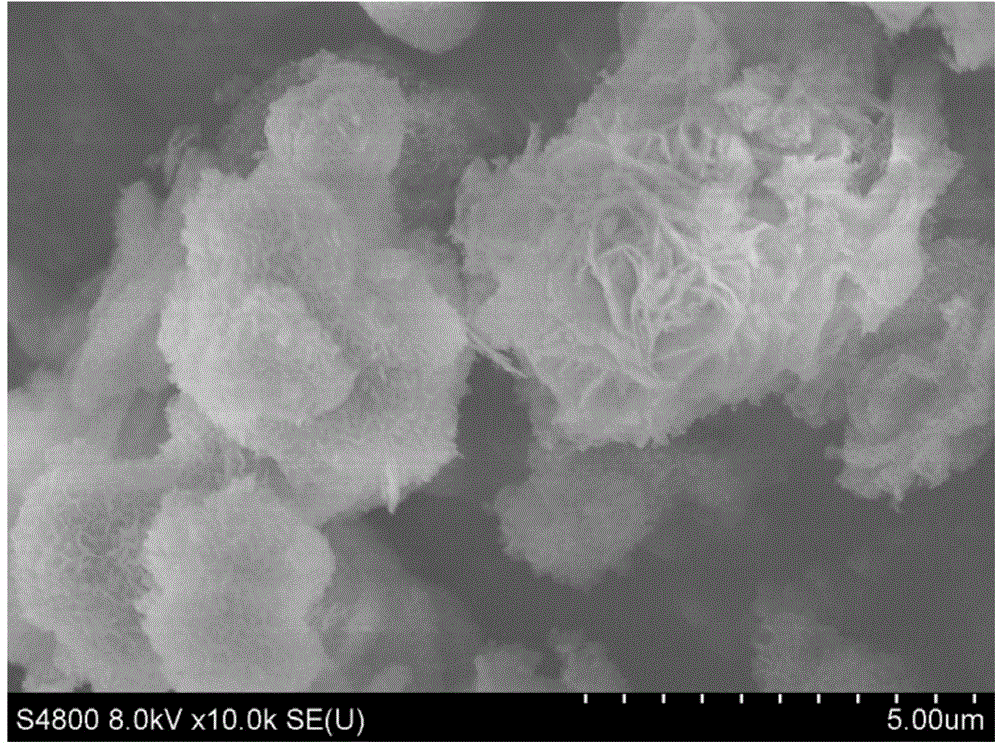

[0050] The present invention has carried out scanning electron microscope detection (SEM) to the three-dimensional nanostructure compound obtained in the present embodiment, the result is as follows figure 1 as shown, figure 1 It is the SEM picture of the petal-shaped intermediate obtained in Example 1 of the present invention;

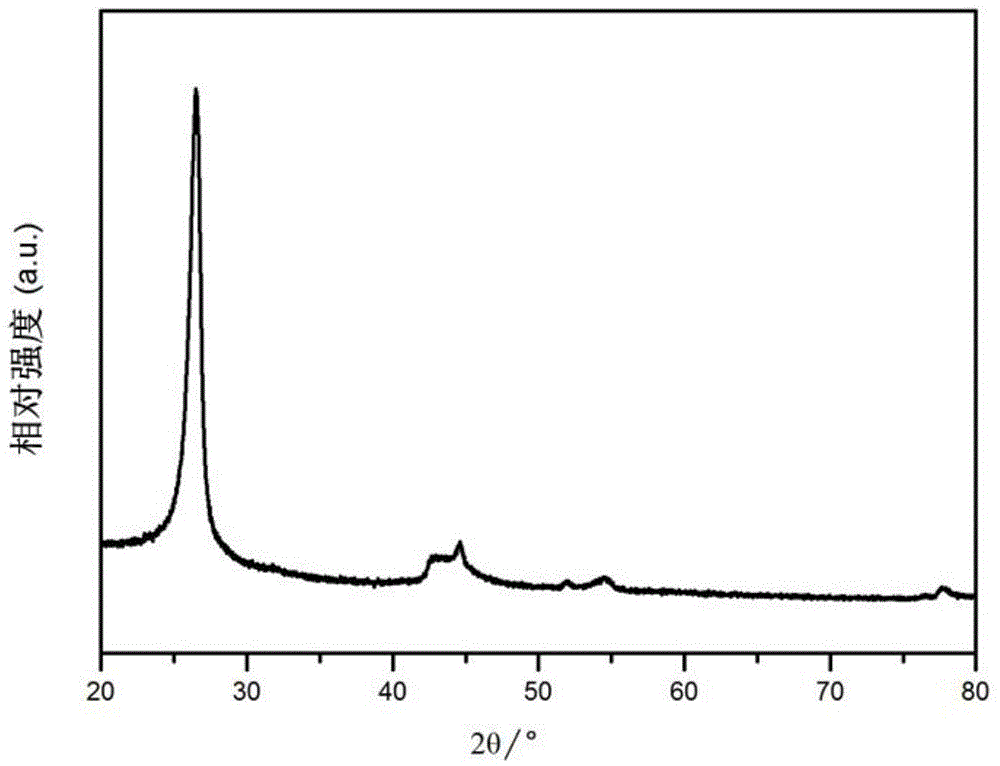

[0051] The present invention has carried out scanning electron microscope detection (SEM) to the graphene t...

Embodiment 2

[0055] Mix 10g of nickel chloride, 10g of P123, 5g of sodium lauryl sulfate with 200ml of water, and stir evenly in a water bath at 28°C; use ammonia water with a mass concentration of 25% to adjust the pH of the solution to 11, and conduct a hydrothermal reaction at 180°C for 6 hours to form Intermediates in the shape of petals.

[0056] Take 1g of the above-mentioned intermediate and mix it with 0.2g KOH and dry it. Then, the dried product is calcined at 1000°C for 2h under a nitrogen atmosphere, and the heating rate is 5°C / min. The calcined product is successively washed with hydrochloric acid with a concentration of 1mol / L. Filter and dry at 120°C to obtain porous graphene.

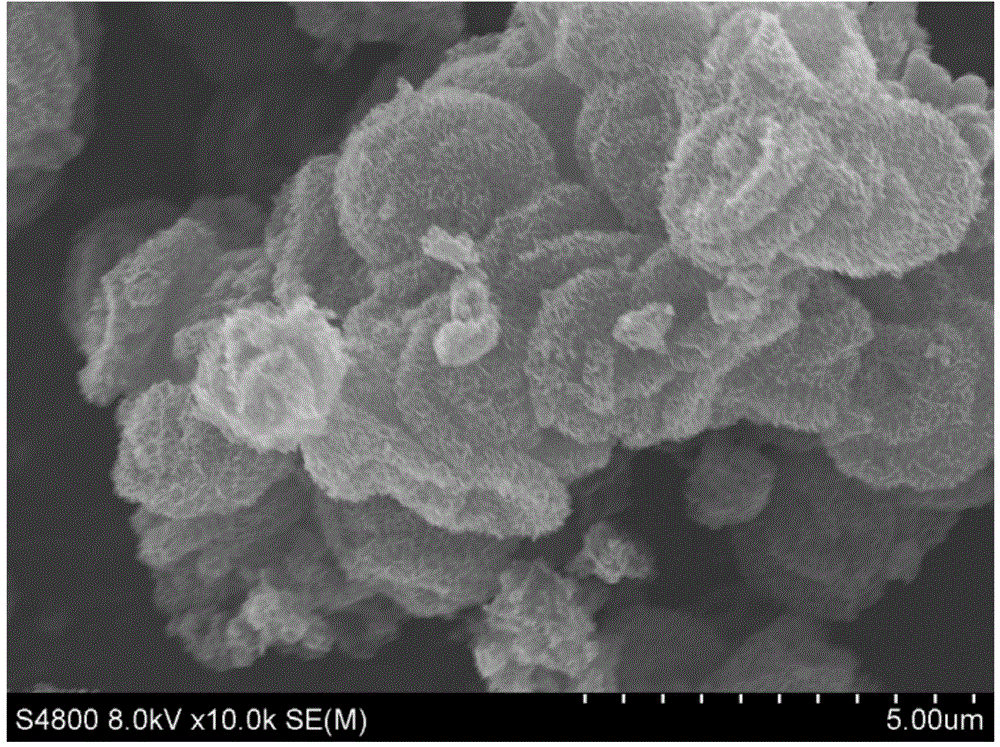

[0057] The present invention has carried out scanning electron microscope detection (SEM) to the intermediate of the petal shape that present embodiment obtains, and the result is as follows Figure 5 as shown, Figure 5 It is the SEM picture of the petal-shaped intermediate obtained in Example 2 of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com