New process for treating synthesized chlorpyrifos

A chlorpyrifos and process technology, which is applied in the field of synthetic chlorpyrifos treatment process, can solve the problems of large capital investment, economic waste, cumbersome process and other problems in wastewater, and achieve the effect of reducing production cost, reducing production volume, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

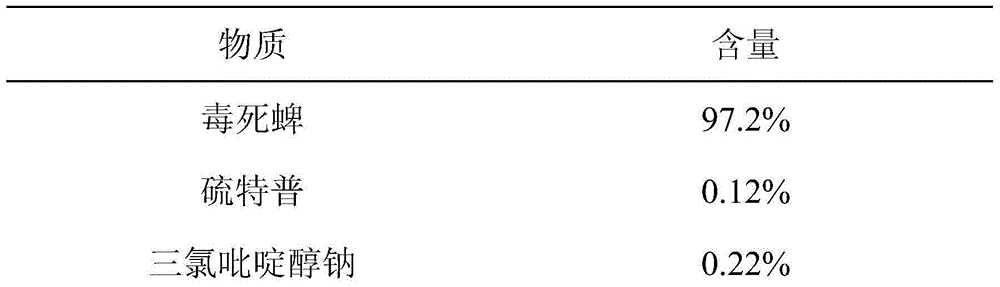

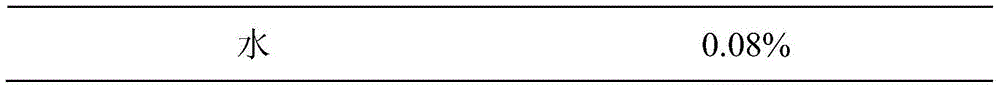

[0015] The sodium clopyridinate and ethyl chloride are reacted with the catalyst, and after the reaction is finished, the mixture is allowed to stand for stratification, and the lower oil phase is removed. Wash the oil phase with hot water at 30-40°C. After washing, let it stand for stratification, separate the water layer to leave the oil phase, then wash the oil phase with alcohol, filter it with suction, and dry it to obtain the white chlorpyrifos technical product.

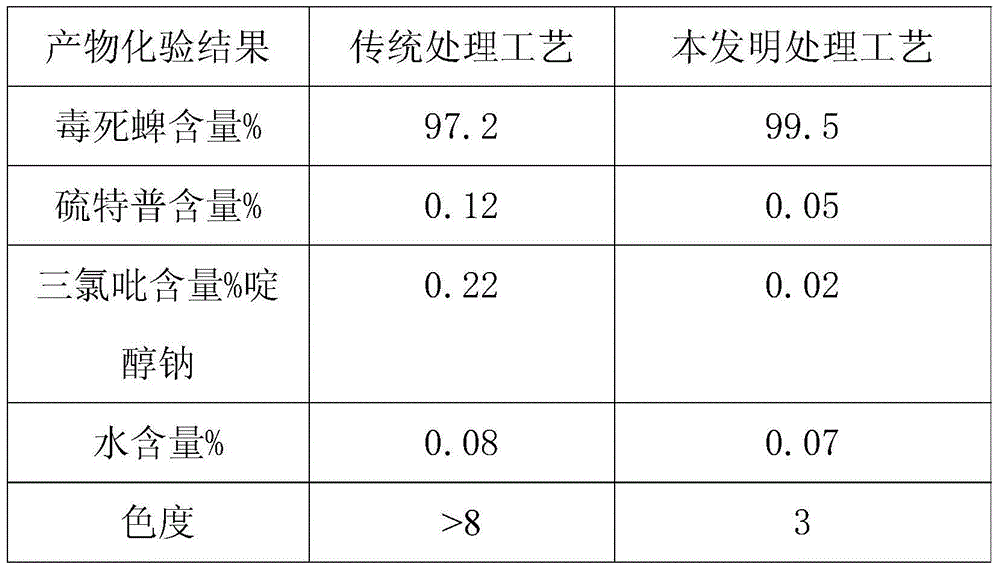

[0016] Technology of the present invention and traditional processing technology are as follows table to the assay result of product:

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com