A kind of preparation method of phenolated lignin amine cationic emulsifier

A cationic emulsifier and phenolized lignin technology, which is applied in building components, building insulation materials, construction, etc., can solve the problem of limited emulsification performance, limited number of active sites of alkali lignin, and inability to introduce lipophilic and hydrophilic functional groups And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

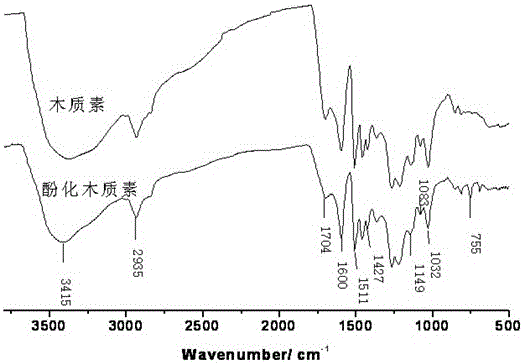

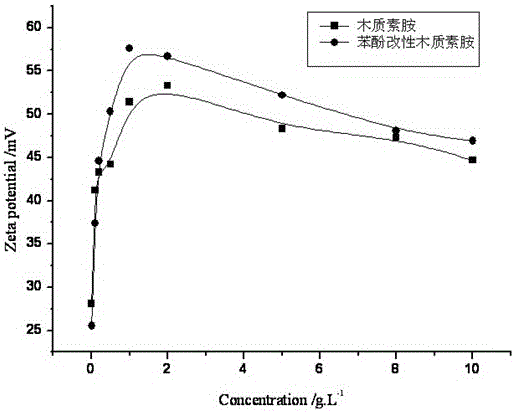

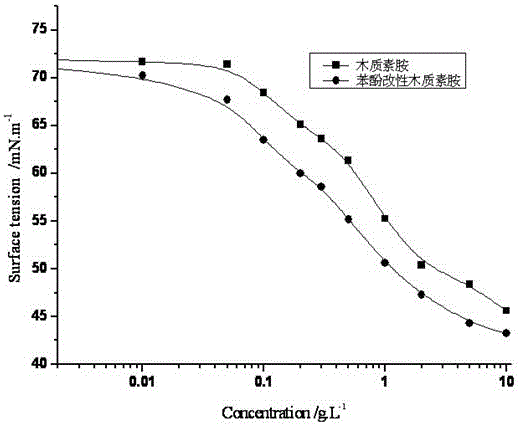

[0049] Weigh 100 parts of wood pulp alkali lignin, 20 parts of phenol, 3 parts of sodium hydroxide and 100 parts of water in parts by weight, add them to a three-necked flask with a condenser tube and a thermometer, stir and dissolve, and keep the reaction mixture at a constant temperature of 70 °C After stirring and reacting for 3 hours, it was acidified with 1 mol / L hydrochloric acid to pH=2.5, filtered with suction, and the filter cake was washed with hot water at 80°C until no free phenol existed to obtain phenolated lignin. Dissolve phenolized lignin with 10% NaOH solution and adjust the pH to 10.5, raise the temperature to 90°C, slowly drop in a mixture of 55 parts of diethylenetriamine and 35 parts of 37% formaldehyde, and stir for 4 hours at a constant temperature. After the reaction is finished, it is cooled to obtain a phenolated lignin amine cationic emulsifier solution, which is acidified and mixed with asphalt to make emulsified asphalt which can be used for road c...

Embodiment 2

[0051] Weigh 100 parts of wood pulp alkali lignin, 25 parts of phenol, 4 parts of sodium hydroxide and 200 parts of water in parts by weight, add them to a three-necked flask with a condenser tube and a thermometer, stir and dissolve, and keep the reaction mixture at a constant temperature of 75 °C After stirring and reacting for 2.5 hours, acidify with 1 mol / L hydrochloric acid to pH=2.5, filter with suction, wash the filter cake with 85°C hot water until no free phenol exists, and obtain phenolated lignin. Dissolve the phenolized lignin with 10% NaOH solution and adjust the pH to 11, raise the temperature to 90°C, slowly drop in a mixture of 80 parts of diethylenetriamine and 38 parts of 37% formaldehyde, and stir for 4 hours at a constant temperature. After the reaction is finished, it is cooled to obtain a phenolated lignin amine cationic emulsifier solution, which can be used for waterproof construction of building toilets.

Embodiment 3

[0053] Weigh 100 parts by weight of bamboo pulp alkali lignin, 30 parts of phenol, 5 parts of sodium hydroxide and 300 parts of water into a three-necked flask with a condenser tube and a thermometer, stir and dissolve, and keep the reaction mixture at a constant temperature of 80 °C After stirring and reacting for 2 hours, it was acidified with 1 mol / L hydrochloric acid to pH=2.5, filtered with suction, and the filter cake was washed with hot water at 90°C until no free phenol existed to obtain phenolated lignin. Dissolve the phenolized lignin with 10% NaOH solution and adjust the pH to 11, raise the temperature to 95°C, slowly drop in a mixture of 110 parts of triethylenetetramine and 40 parts of 37% formaldehyde, and stir for 3 hours at a constant temperature. After the reaction is finished, it is cooled to obtain a phenolated lignin amine cationic emulsifier solution, which can be used for road construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com