A polylactic acid composite material for promoting bone growth and biocompatibility and its preparation method

A technology of biocompatibility and composite materials, applied in the field of polylactic acid composite materials and preparations that promote bone growth and biocompatibility, can solve the problem that the stability is not enough to alleviate the acidic environment of PLA, unfavorable cell growth and adhesion, Low cytocompatibility and other issues, to achieve considerable economic benefits, reduce the cost of bone repair, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

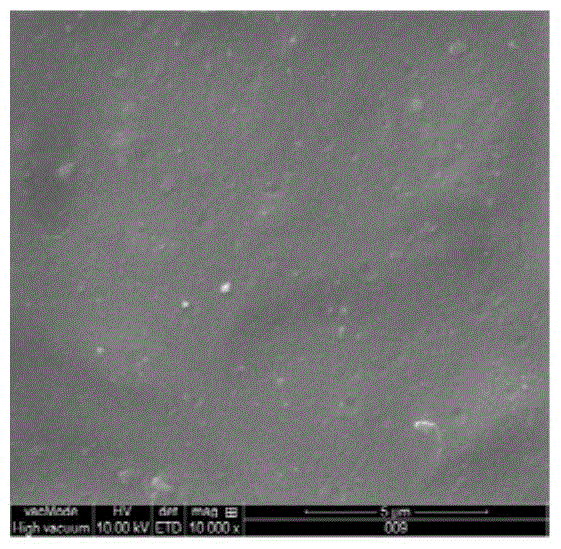

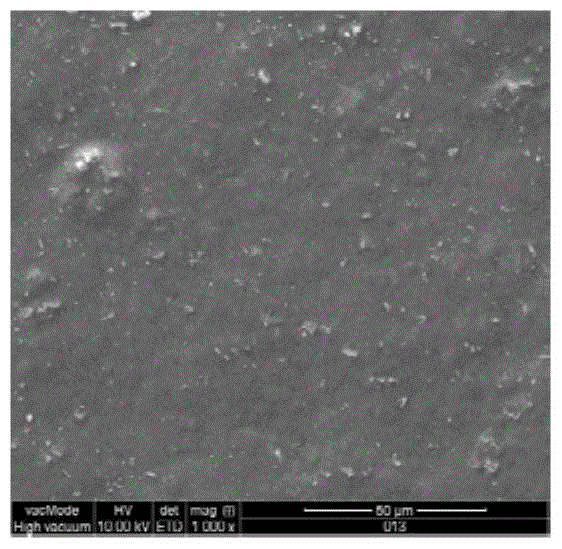

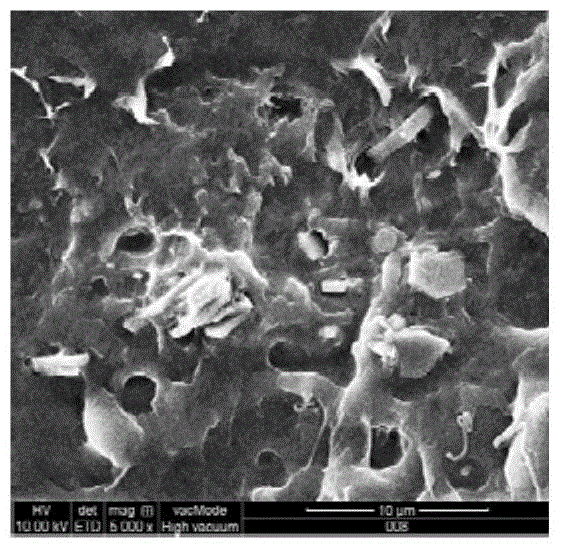

Image

Examples

Embodiment 1

[0035] A method for preparing a polylactic acid composite material that promotes bone growth and biocompatibility, comprising:

[0036] (1) Surface activation treatment of pearl powder

[0037] Pearl powder with a particle size of 100nm is added to deionized water, and polyethylene glycol powder with a degree of polymerization of 4000Da is added at the same time. The mass ratio of polyethylene glycol to pearl powder is 2:98. The mass of the two is equal to the mass of deionized water. The ratio is 1:10. After stirring and ultrasonication, freeze at -15°C for 12h, wherein the stirring rate is 1000rpm, the ultrasonic power is 50KHz, and the time is 0.5h each, and then freeze-dry at -55°C for 20h to obtain polyethylene oxide. Diol surface modified pearl powder;

[0038] (2) Preparation of polylactic acid composite material;

[0039] Polylactic acid with a weight-average molecular weight of 70,000 is dissolved in chloroform solvent to form a solution with a mass fraction of 5 wt...

Embodiment 2

[0042] A method for preparing a polylactic acid composite material that promotes bone growth and biocompatibility, comprising:

[0043] (1) Surface activation treatment of pearl powder

[0044] Pearl powder with a particle size of 400nm is added to deionized water, and polyethylene glycol powder with a degree of polymerization of 10000Da is added at the same time. The mass ratio of polyethylene glycol to pearl powder is 5:95. The mass of the two is equal to the mass of deionized water. The ratio is 1:20. After stirring and ultrasonication, freeze at -20°C for 15h, wherein the stirring rate is 500rpm, the ultrasonic power is 40KHz, and the time is 1h each, and then freeze-dry at -45°C for 24h to obtain polyethylene glycol. Alcohol surface modified pearl powder;

[0045] (2) Preparation of polylactic acid composite material;

[0046] Polylactic acid with a weight-average molecular weight of 200,000 is dissolved in 1,4-dioxane solvent to form a solution with a mass fraction of ...

Embodiment 3

[0049] A method for preparing a polylactic acid composite material that promotes bone growth and biocompatibility, comprising:

[0050] (1) Surface activation treatment of pearl powder

[0051] Pearl powder with a particle size of 300nm is added to deionized water, and polyethylene glycol powder with a degree of polymerization of 5000Da is added at the same time. The mass ratio of polyethylene glycol to pearl powder is 2:98. The mass of the two and the mass of deionized water The ratio is 1:18. After stirring and ultrasonication, freeze at -16°C for 12h, wherein, the stirring rate is 600rpm, the ultrasonic power is 45KHz, and the time is 0.6h each, and then freeze-dry at -50°C for 22h to obtain polyethylene oxide. Diol surface modified pearl powder;

[0052] (2) Preparation of polylactic acid composite material;

[0053] Polylactic acid with a weight-average molecular weight of 150,000 was dissolved in 1,4-dioxane solvent to form a solution with a mass fraction of 8 wt%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com