The controlled releasing method by using active pearl material instead of bone growth factors in the bone restoration

A technology of bone growth factors and active substances, which is applied in the field of controlled release of bone growth factors replaced by pearl active substances in bone repair, can solve the problems of reduced activity of pearls, and achieve scale, simple production process, and wide sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the natural degradation of pearl powder

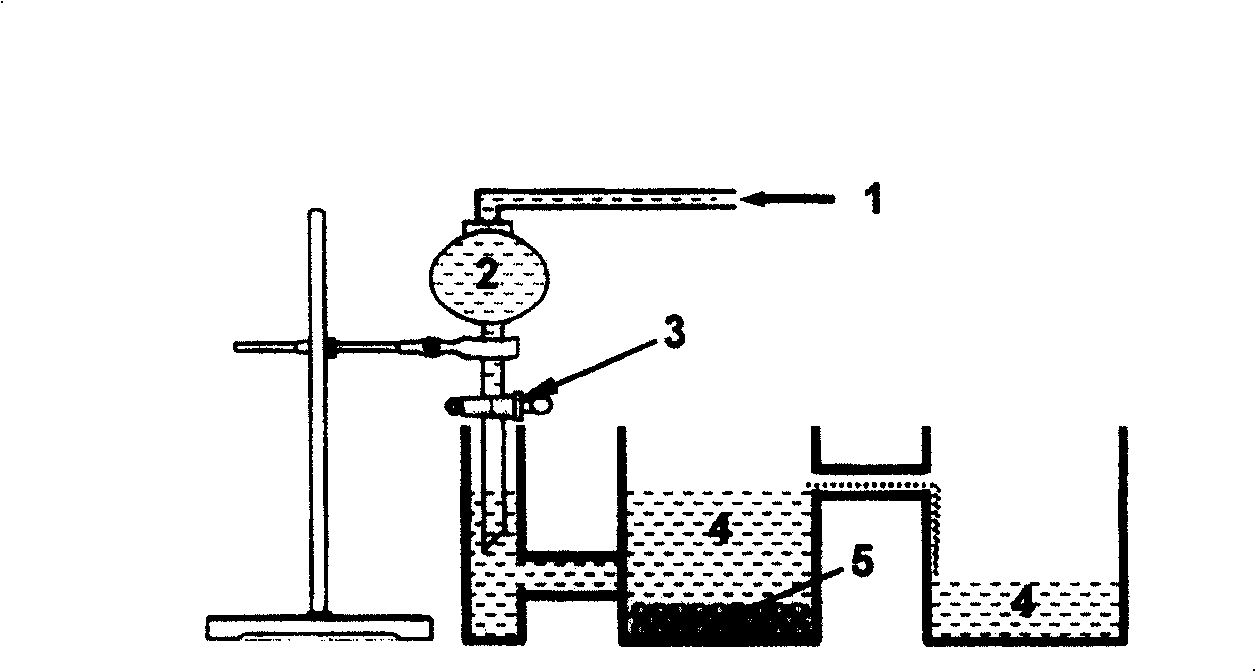

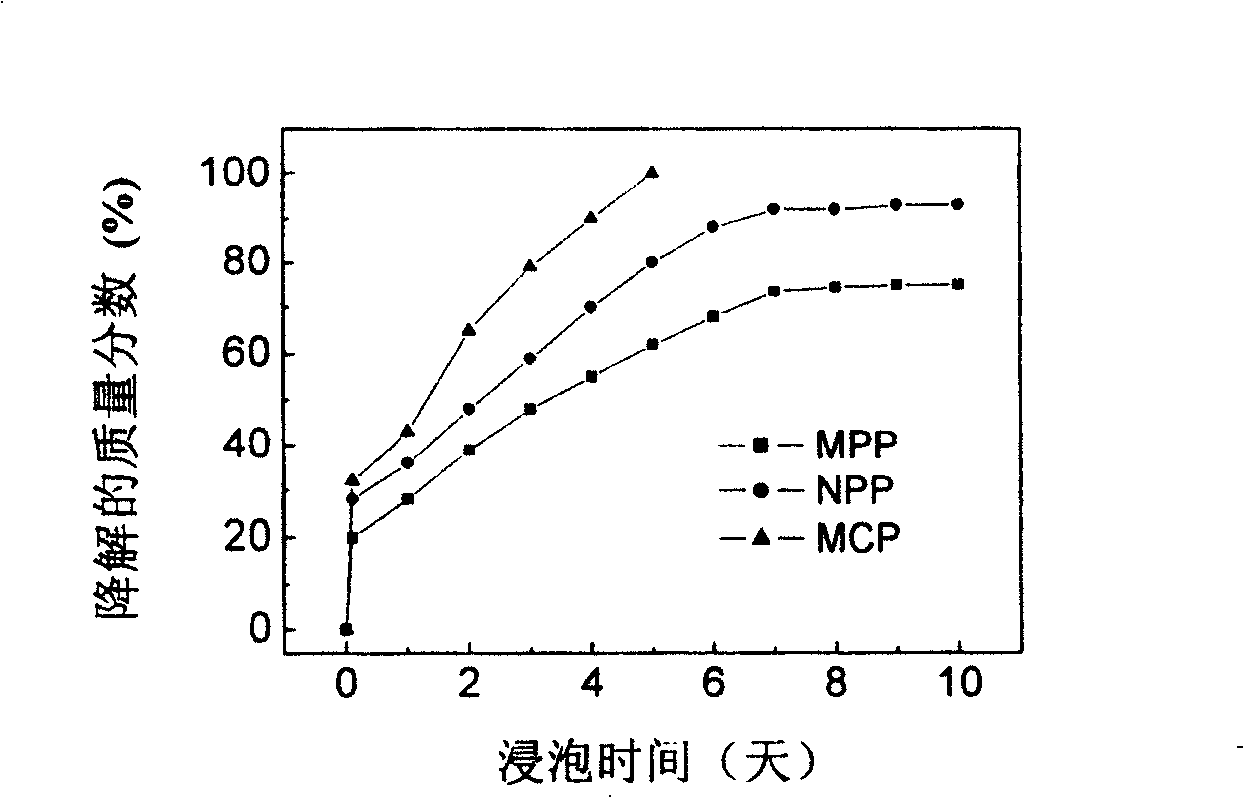

[0029] Once the pearl powder is nano-sized, its degradation speed and degradation degree will be greatly improved. Obviously, the degradation of pearl powder must be closely related to its unique nano-organic-inorganic hierarchical structure, which is similar to that of pure CaCO 3 In contrast, the degradation of pearl powder must have its particularity, and the degradation of pearl powder will also have size dependence. The present invention is to nanopearl powder (NPP, main particle diameter is about 50-150nm, micron pearl powder (MPP, main particle diameter is about 1-5 μm) and pure CaCO 3 Reagent powder (MCP, about 1 μm in size) was subjected to degradation experiments in flowing deionized water, and the experimental equipment was as follows: figure 1 shown. The original forms of the three powders are as figure 2 shown. The pearl powder used is the product of Zhejiang Changshengniao Pharmaceutical Co., Lt...

Embodiment 2

[0039] The superfine pearl powder product (component I) and nano pearl powder product (component II) of Changshengniao Pharmaceutical Co., Ltd. were vacuum-dried at 60°C for 3 hours, wherein the main particle size of the superfine pearl powder was about 1- 5 μ m, the main particle diameter of nano pearl powder is about 50-150nm, component I and component II get 4 grams (40%wt.%) and 6 grams (60%wt.%) respectively, and then they are placed together in agate Mix in a mortar for 1 hour to obtain a composition of the two, and vacuum-dry the composition at 60° C. for 2 hours, and finally pack and sterilize the composition for use.

Embodiment 3

[0041] Common micron pearl powder purchased in the market was vacuum-dried at 60°C for 3 hours, then sieved with a vibrating sieve at -100 mesh and +120 mesh to obtain pearl powder (component I) with a diameter of 132 μm to 154 μm, and then Sieve -120 mesh pearl powder -325 mesh and +350 mesh to obtain pearl powder (component II) with a diameter of 48 μm ~ 50 μm. The superfine pearl powder product (component III) and nano pearl powder product (component IV) of Changshengniao Pharmaceutical Co., Ltd. were vacuum-dried at 60°C for 3 hours, wherein the main particle size of the superfine pearl powder was about 1- 5 μ m, the main particle diameter of nano pearl powder is about 50-150nm; 10%wt.%), 2g (20%wt.%), 3g (30%wt.%), 3g (30%wt.%), and then they were mixed together in an agate mortar for 1 hour to The five compositions were obtained, and the compositions were vacuum-dried at 60° C. for 2 hours, and finally the compositions were packaged and sterilized for use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com