A kind of preparation method of fluorine-containing iodohydrocarbon composition

A technology of composition and iodocarbon, which is applied in the field of preparation of fluorine-containing iodocarbon composition, can solve the problems affecting the heat transfer performance of refrigerant products, increasing equipment investment and energy consumption, and the influence of two-phase mixing degree, etc., to achieve Good lubricant compatibility and heat transfer properties, improved heat transfer, enhanced solubility and diffusivity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

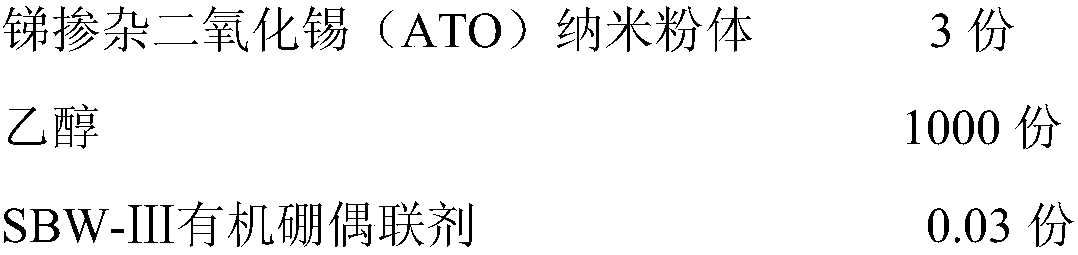

[0031] The preparation of step (1) nano-compatibilizer, by every part of 1Kg, the feeding ratio is as follows:

[0032]

[0033]

[0034] The preparation method is:

[0035] According to the ratio, in the stirred reactor, 3 parts Antimony-doped tin dioxide (ATO) nanopowderDisperse in 1000 parts of ethanol, then add 0.03 parts of SBW-Ⅲ organic boron coupling agent, react at room temperature (25°C) for 5 hours, then add 50 parts of polyalkylene glycol (PAG) lubricant, 2 parts of 2,6 -Nadienol, reacted for 2 hours at normal temperature (25° C.) to obtain a nano-compatibilizer for future use.

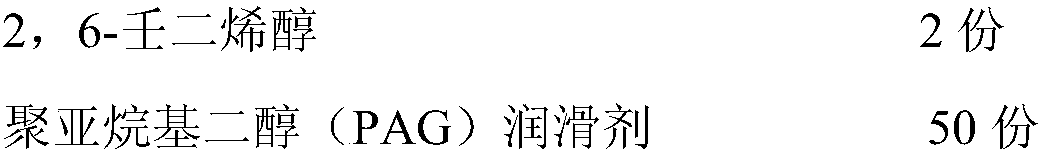

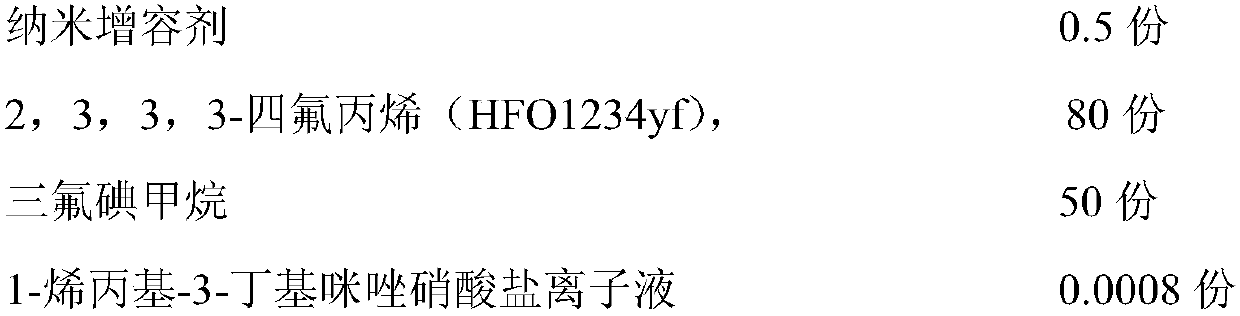

[0036] Step (2) mixing, according to every 1Kg, the feeding ratio is as follows:

[0037]

[0038] The preparation method is: according to the proportion, mix 0.5 parts of the nano-compatibilizer prepared in step (1) with 80 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 50 parts of trifluoroiodomethane, 0.0008 parts of 1- Allyl-3-butylimidazole nitrate ionic liquid was pre-mi...

Embodiment 2

[0040] The preparation of step (1) nano-compatibilizer, by every part of 1Kg, the feeding ratio is as follows:

[0041]

[0042] The preparation method is: according to the proportion, in a stirred reactor, 1 part Antimony-doped tin dioxide (ATO) nanopowder Scatter to 1000 Parts of ethanol, then add SBW-Ⅲ organoboron coupling agent 0.01 Parts, reacted at room temperature (25°C) for 4h, then added many Polyol ester (POE) lubricant 10 1 part, 1 part of 2,6-nonadienol, reacted at room temperature (25° C.) for 4 hours to obtain a nano-compatibilizer.

[0043] Step (2) mixing, according to every 1Kg, the feeding ratio is as follows:

[0044]

[0045] The preparation method is: mix 1 part of the nano-compatibilizer prepared in step (1) with 700 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 300 parts of trifluoroiodomethane, 0.005 parts of 1- Allyl-3-butylimidazole nitrate ionic liquid was pre-mixed in the liquid phase for 20h in a stirred reactor, and then added to ...

Embodiment 3

[0047] The preparation of step (1) nano-compatibilizer, by every part of 1Kg, the feeding ratio is as follows:

[0048]

[0049] The preparation method is: according to the proportion, in a stirred reactor, 5 parts Antimony-doped tin dioxide (ATO) nanopowder Disperse in 1000 parts of ethanol, then add 0.05 parts of SBW-Ⅲ organoboron coupling agent, react at room temperature (25°C) for 3 hours, then add 100 parts of polyalkylene glycol (PAG) lubricant, 2,6-nonyl 5 parts of dienol were reacted at room temperature (25° C.) for 6 hours to obtain a nano-compatibilizer.

[0050] Step (2) mixing, according to every 1Kg, the feeding ratio is as follows:

[0051]

[0052] The preparation method is: mix 10 parts of the nano-compatibilizer prepared in step (1) with 900 parts of 2,3,3,3-tetrafluoropropene (HFO1234yf), 100 parts of trifluoroiodomethane, 0.01 parts of 1- Allyl-3-butylimidazole nitrate ionic liquid is premixed 30h under the liquid phase in the stirred reactor, then j...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com