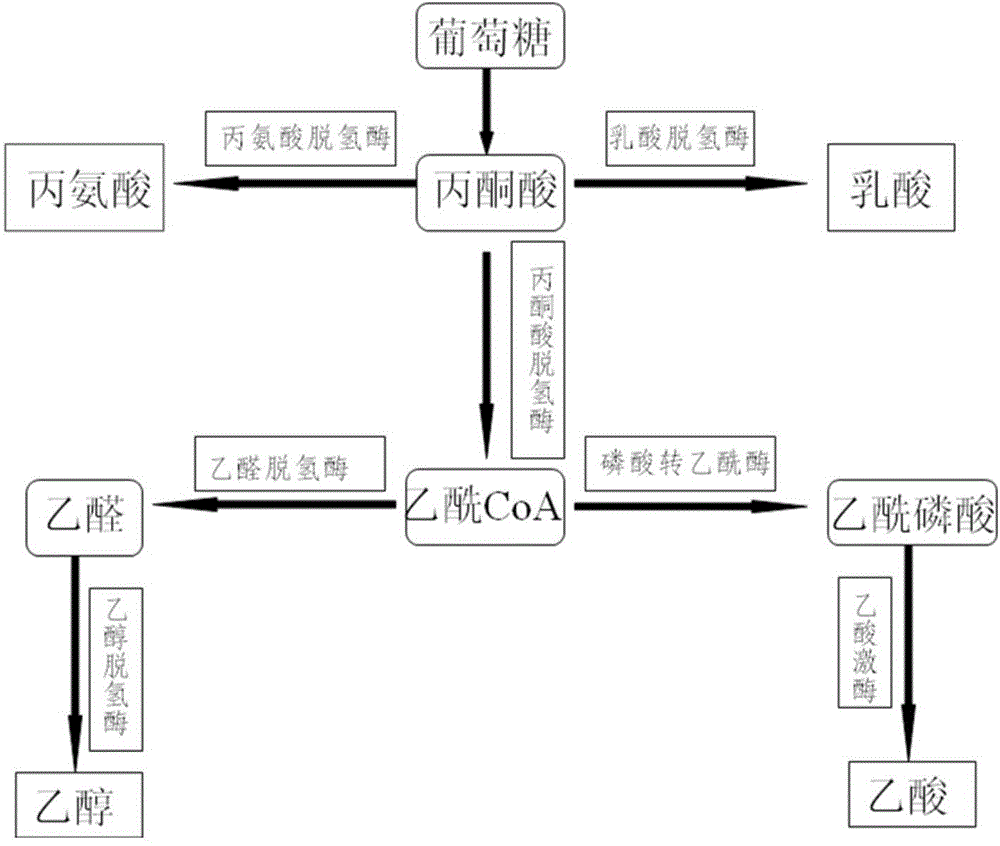

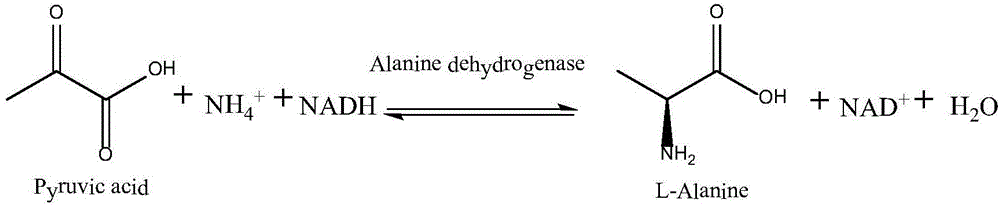

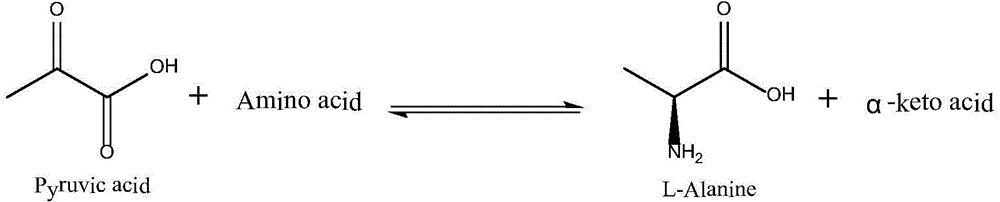

Construction method of bacillus subtilis engineering bacteria for high yielding of alanine

A technology of Bacillus subtilis and construction method, applied in the field of microbiology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] (1) The methods used in the following examples are conventional methods unless otherwise specified, and the B. subtilis IBL23 used is the serial number of the model strain B. subtilis 168 in our laboratory.

[0038] 1. Construction of lactate dehydrogenase single gene knockout mutant B. subtilis IBL23-ldh

[0039] The build method includes the following steps:

[0040] 1.1B.subtilis IBL23 genome extraction

[0041] Genomic DNA of B. subtilis IBL23 was extracted using Shanghai Sangon SK8255 kit

[0042] 1). Take 1ml of B. subtilis IBL23 cultured overnight, add it to a 1.5ml EP tube, centrifuge at room temperature for 1 minute at 8000 rpm, discard the supernatant thoroughly, and collect the bacteria.

[0043] 2). Add 180 μl of 20 mg / ml lysozyme solution to resuspend the bacteria, bathe in 37°C water for 0.5-1 hour, and invert the EP tube every 5-10 minutes while in the water bath.

[0044] 3). Add 20 μl of proteinase K solution and oscillate with a fast mixer to mix. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com