Antistatic blended yarn and preparation method thereof

A blended yarn and antistatic technology, which is applied in the field of clothing fabrics, can solve the problems of poor antistatic performance of antistatic yarn fabrics, weakening antistatic ability of antistatic yarns, and yarns without antistatic functions. The effect of avoiding charge accumulation, dimensional stability, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

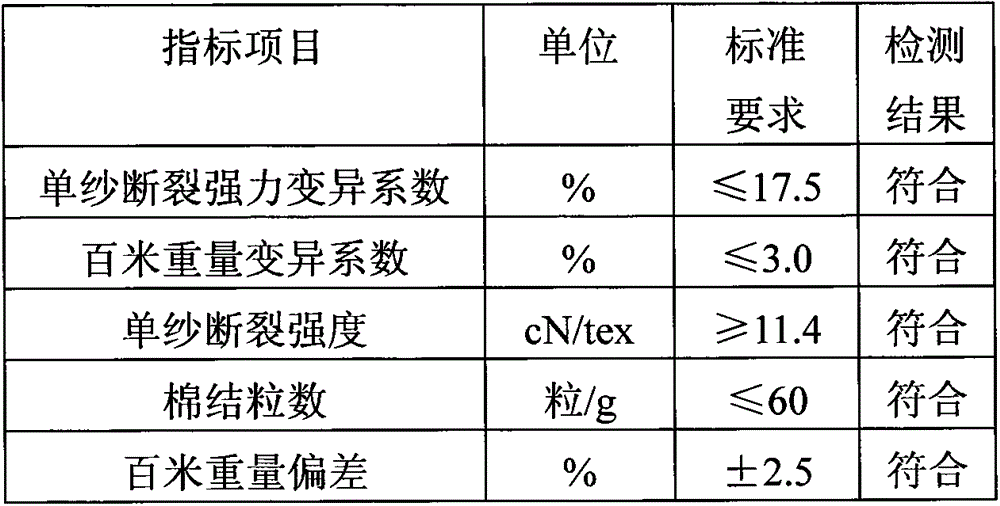

Image

Examples

Embodiment 1

[0052] An antistatic blended yarn made of 20% cotton fiber (combed cotton, fine count yarn 45s) by mass percentage, 60% viscose fiber (rich and strong fiber, specification 75D / 30f) and 20% The polyamide fiber is blended, wherein: the polyamide fiber is antistatic pretreated polyamide fiber, and the antistatic pretreated polyamide fiber is prepared by the following method:

[0053] (1) Nylon 6 slices and 0.5% antistatic agent KJD-1, 2% Yunqing brand internally added antistatic agent, 0.5% antioxidant 168, 0.5% dispersant paraffin wax by weight of nylon 6 slices, melted together Nylon masterbatch is produced by mixing and extruding. The main process parameters of melt blending are: the melt temperature of nylon 6 is 200°C, the screw speed is 15r / min, and the die temperature is 170°C.

[0054] (2) Nylon 6 slices are added with 4% nylon masterbatch based on the weight of nylon 6 slices and mixed with melt spinning to obtain antistatic nylon fibers. The main process parameters of m...

Embodiment 2

[0077] An antistatic blended yarn is made of 30% cotton fiber (combed cotton, fine count yarn 45s) by mass percentage, 55% viscose fiber (rich fiber, specification is 75D / 30f) and 15% The polyamide fiber is blended, wherein: the polyamide fiber is antistatic pretreated polyamide fiber, and the antistatic pretreated polyamide fiber is prepared by the following method:

[0078] (1) Nylon 6 slices and 2% antistatic agent KJD-1, 4% Yunqing brand internally added antistatic agent, 1% antioxidant 168, 1% dispersant paraffin wax by weight of nylon 6 slices, melted together Nylon masterbatch is produced by mixing and extruding. The main process parameters of melt blending are: the melt temperature of nylon 6 is 250°C, the screw speed is 30r / min, and the die temperature is 230°C.

[0079] (2) Nylon 6 slices are added with 7% nylon masterbatch based on the weight of nylon 6 slices and mixed with melt spinning to obtain antistatic nylon fibers. The main process parameters of melt spinnin...

Embodiment 3

[0102]An antistatic blended yarn made of 20% cotton fiber (combed cotton, fine count yarn 45s) by mass percentage, 58% viscose fiber (rich and strong fiber, specification 75D / 30f) and 22% The polyamide fiber is blended, wherein: the polyamide fiber is antistatic pretreated polyamide fiber, and the antistatic pretreated polyamide fiber is prepared by the following method:

[0103] (1) Nylon 6 slices and 0.5% antistatic agent KJD-1, 3% Yunqing brand internal antistatic agent, 1% antioxidant 168, 1% dispersant paraffin wax by weight of nylon 6 slices, melted together Nylon masterbatch is produced by mixing and extruding. The main process parameters of melt blending are: nylon 6 melt temperature is 220°C, screw speed is 20r / min, die temperature is 210°C,

[0104] (2) Nylon 6 slices are added with 4-7% nylon masterbatch based on the weight of nylon 6 slices and mixed with melt spinning to obtain antistatic nylon fibers. The main process parameters of melt spinning are: the screw pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com