Nitrogen-doped graphitization carbon encapsulation iron nanoparticle preparation method

A graphitized carbon and nanoparticle technology, applied in chemical instruments and methods, nanotechnology, chemical/physical processes, etc., can solve problems such as differences and differences in preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

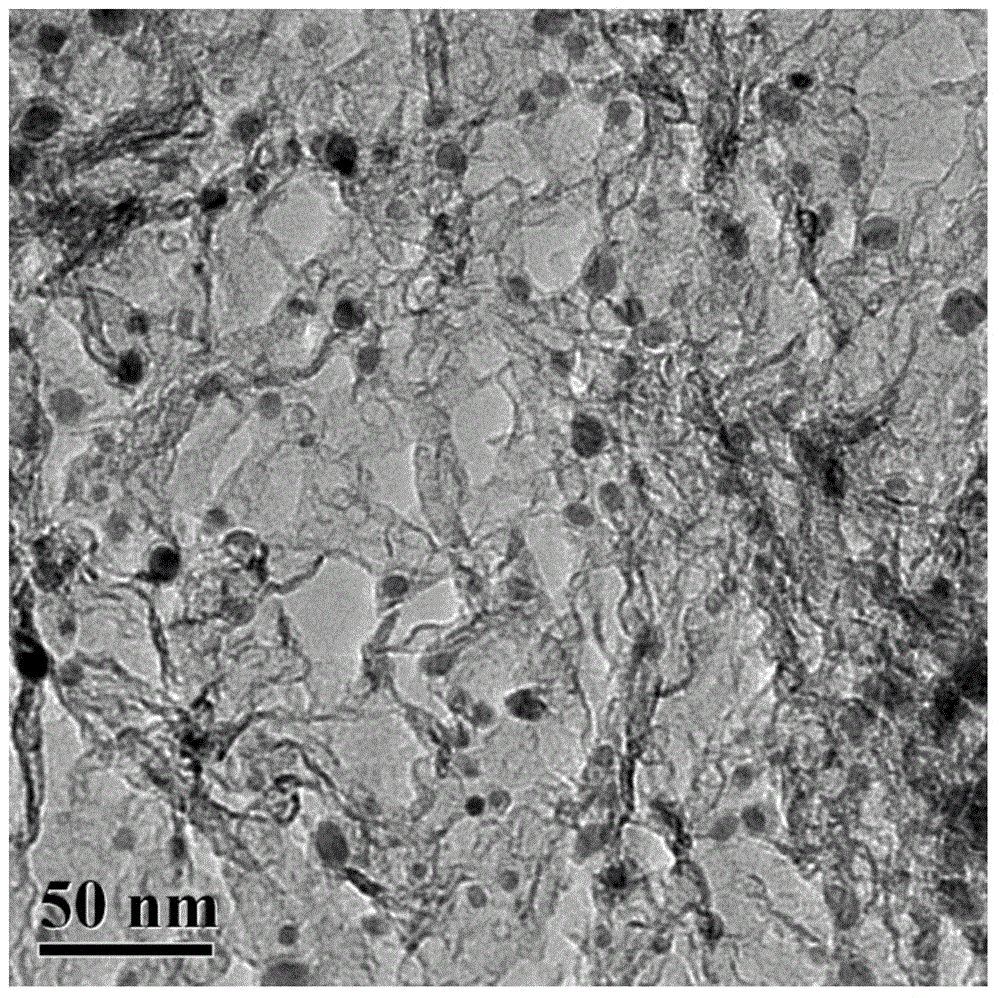

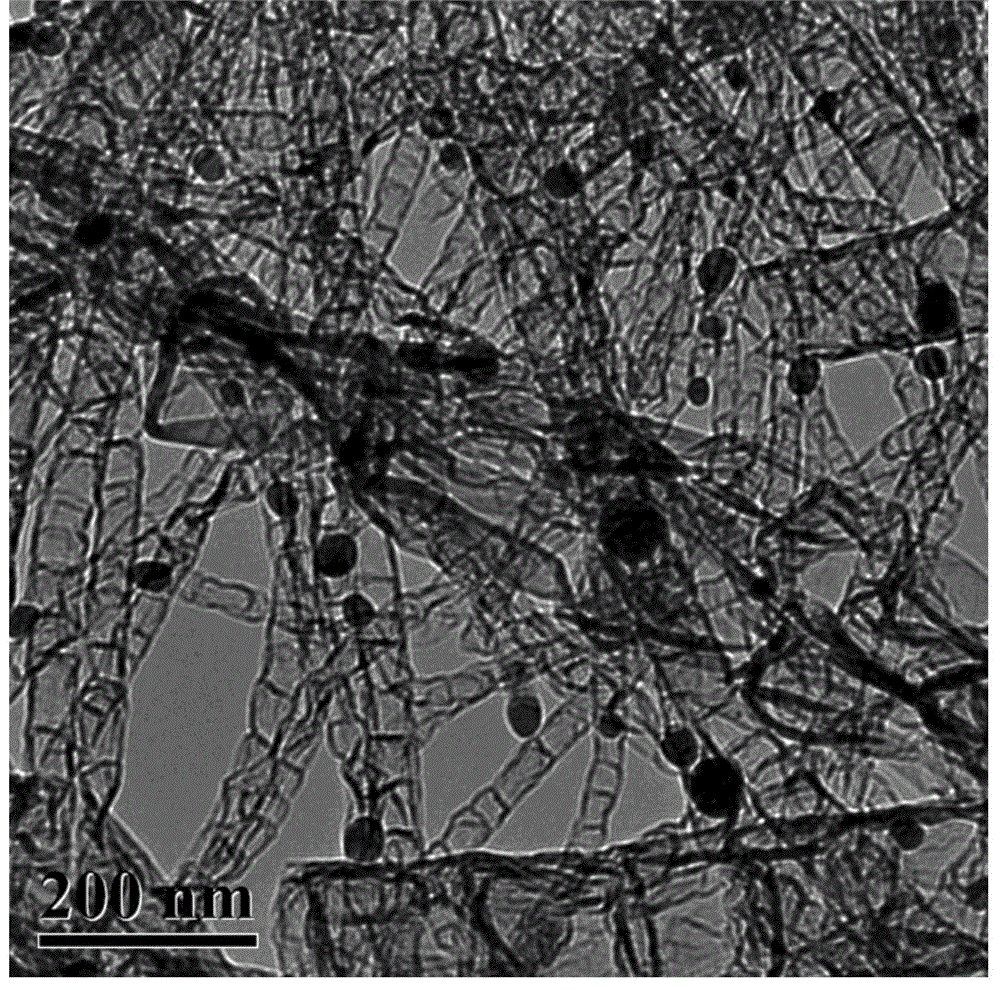

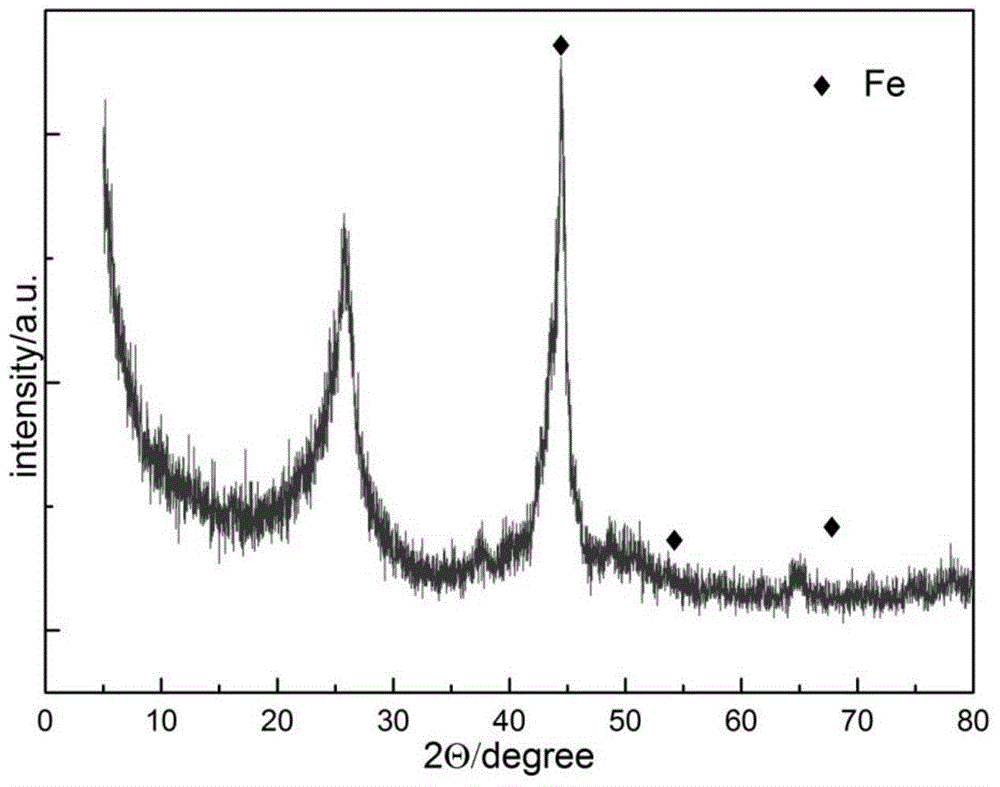

[0028] Weigh 10g ferric ammonium citrate and 1g dicyandiamide and dissolve them in 150mL water respectively, mix well and remove the solvent at 90°C; put the solid mixture in a quartz boat, then put it into a tube furnace equipped with a quartz tube, At a flow rate of 100mL min -1 Under nitrogen atmosphere, at 5°C min -1 Raise the temperature to 600 °C at a rate of 5 hours, and take it out after cooling to room temperature. The obtained solid was dissolved in 0.1molL -1 HClO 4 The solution is treated under stirring at 80° C. for 24 hours, filtered and washed with water and dried to obtain a nitrogen-doped graphitized carbon-encapsulated iron nanoparticle material.

Embodiment 2

[0030] Weigh 10g of ferric ammonium citrate and 10g of dicyandiamide and dissolve them in 150ml of water respectively, mix well and remove the solvent at 90°C; put the solid mixture in a quartz boat, then put it into a tube furnace equipped with a quartz tube, At a flow rate of 50mL min -1 Under argon atmosphere, at 10°C min -1 Raise the temperature at a rate of 800°C and keep it for 2 hours, and take it out after cooling to room temperature. Dilute the obtained solid in 1molL -1 In the HCl solution, the mixture was treated at 80° C. for 24 hours under stirring, filtered and washed with water and dried to obtain a nitrogen-doped graphitized carbon-encapsulated iron nanoparticle material.

Embodiment 3

[0032] Weigh 1g of ferric ammonium citrate and 20g of dicyandiamide and dissolve them in 300mL of water respectively, mix well and remove the solvent at 90°C; put the solid mixture in a quartz boat, and then put it into a tube furnace equipped with a quartz tube, At a flow rate of 150mL min -1 Under nitrogen atmosphere, at 20°C min -1 The temperature was raised to 1100° C. and kept for 3 hours, then cooled to room temperature and taken out. The obtained solid was dissolved in 0.5molL -1 HNO 3 The solution is treated under stirring at 80° C. for 24 hours, filtered and washed with water and dried to obtain a nitrogen-doped graphitized carbon-encapsulated iron nanoparticle material.

[0033] The relevant parameter of prepared material in the embodiment 1-3 of table 1

[0034]

[0035] In the material of the present invention, the size of iron nanoparticles is between 1-20nm, the iron loading is between 2-20wt%, and the content of doped nitrogen is between 1-10wt%. The mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com