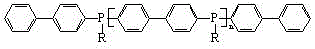

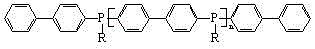

Alkylphosphine oligomer and its synthesis method

A synthesis method and oligomer technology, applied in the field of alkylphosphine oligomers and their synthesis, can solve the problems of low thermal stability, poor acid and alkali resistance, poor solvent resistance, easy hydrolysis, etc., and achieve good char formation ability , good solvent resistance and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Connect a 2000mL four-neck flask to a mechanical stirrer and a constant pressure dropping funnel. Add 149.8 g of 4,4'-dibromobiphenyl and 600 mL of solvent tetrahydrofuran into the four-neck flask. Place the four-necked bottle in a cold well, cool it to -70°C and maintain it for 30 minutes, at this temperature, add a solution of n-butyllithium in n-hexane (2.5M, 384mL) and 3.32g of tetramethylethylenediamine by constant pressure dropwise The liquid funnel was added slowly, and the dropping time was 2h. With the addition of n-butyllithium, the temperature of the system rises spontaneously. After the dropwise addition, the temperature of the system was slowly raised to 25° C. and stirred at this temperature for 1 h.

[0029] 2) Re-cool the four-neck flask to lower the system temperature to -5°C. Slowly drop 46.8 g of methylphosphine dichloride into the reaction flask through a constant pressure dropping funnel, and keep the temperature of the system not exceeding 20...

Embodiment 2

[0035] 1) Connect a 2000mL four-neck flask to a mechanical stirrer and a constant pressure dropping funnel. Add 149.8 g of 4,4'-dibromobiphenyl and 600 mL of solvent n-butyl ether into the four-neck flask. Place the four-necked bottle in a cold well, cool it to -70°C and maintain it for 30 minutes, at this temperature, add a solution of n-butyllithium in n-hexane (2.5M, 384mL) and 3.32g of tetramethylethylenediamine by constant pressure dropwise The liquid funnel was added slowly, and the dropping time was 2h. With the addition of n-butyllithium, the temperature of the system rises spontaneously. After the dropwise addition, the temperature of the system was slowly raised to 25° C. and stirred at this temperature for 1 h.

[0036] 2) Re-cool the four-neck flask to lower the system temperature to -5°C. Slowly drop 70.0 g of n-butylphosphine dichloride into the reaction flask through a constant pressure dropping funnel, and keep the temperature of the system not exceeding 20°...

Embodiment 3

[0042] 1) Connect a 2000mL four-neck flask to a mechanical stirrer and a constant pressure dropping funnel. Add 149.8 g of 4,4'-dibromobiphenyl and 600 mL of solvent anisole into the four-neck flask. Place the four-neck bottle in a cold well, cool to -70°C and maintain it for 30 minutes, at this temperature, add n-butyllithium in n-hexane (2.5M, 384mL) and N,N-dimethylethylenediamine 3.32g Add slowly from the constant pressure dropping funnel, and the dropping time is 2h. With the addition of n-butyllithium, the temperature of the system rises spontaneously. After the dropwise addition, the temperature of the system was slowly raised to 25° C. and stirred at this temperature for 1 h.

[0043] 2) Re-cool the four-neck flask to lower the system temperature to -5°C. Slowly drop 63.6 g of tert-butylphosphine dichloride into the reaction flask through a constant pressure dropping funnel, and keep the temperature of the system not exceeding 20°C during the dropping process. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com