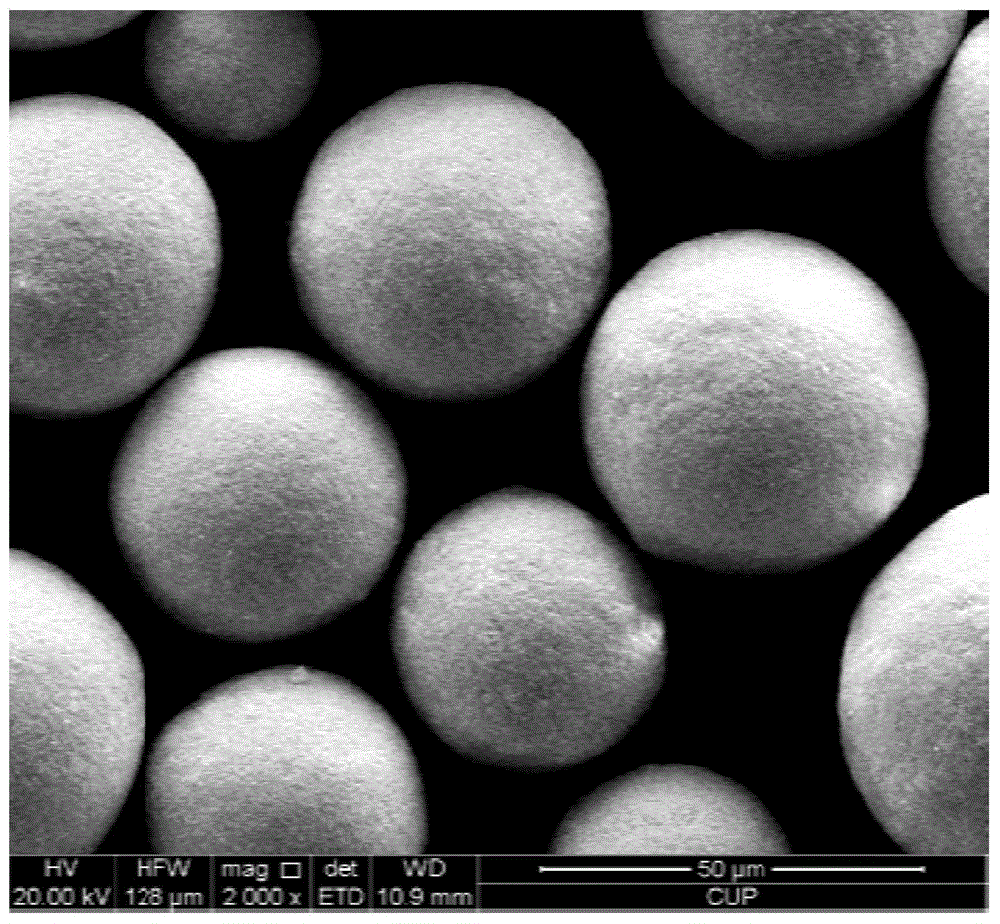

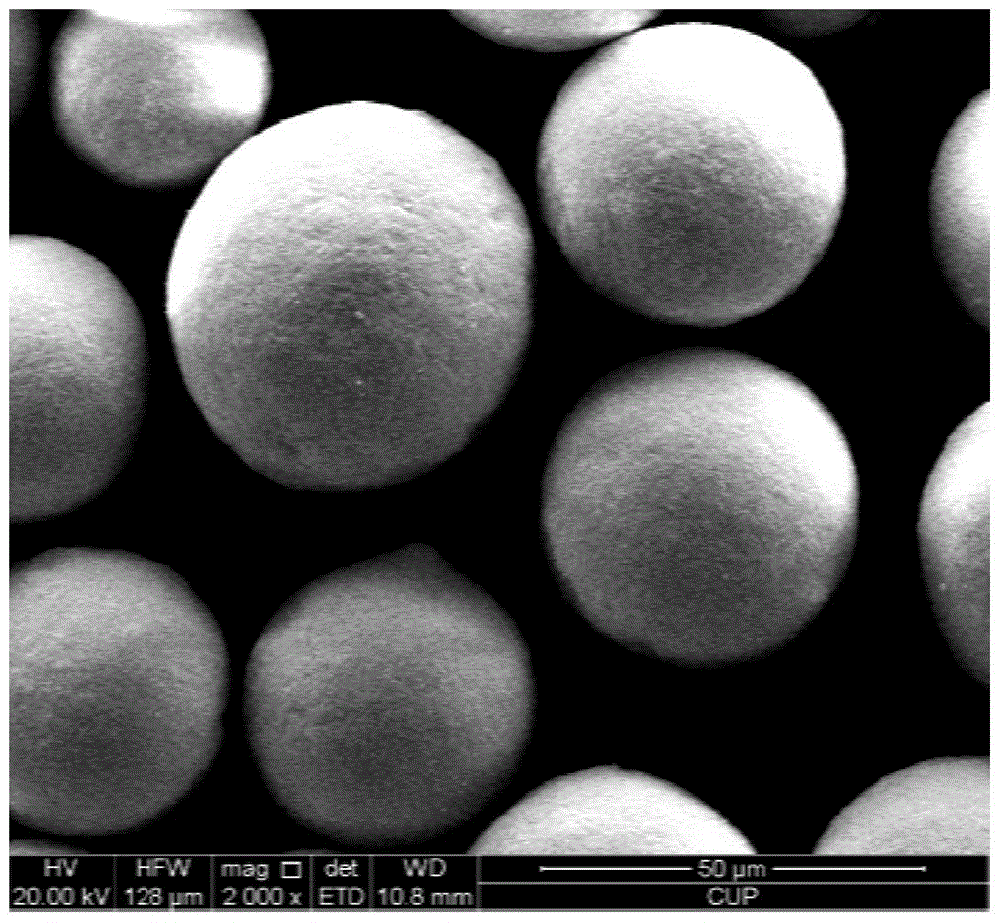

Microspherical catalyst for preparing oil and paraffin from syngas and preparation method thereof

A catalyst and synthesis gas technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, recovery/refining of mineral waxes, etc. Good, high conversion rate, simple and continuous synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

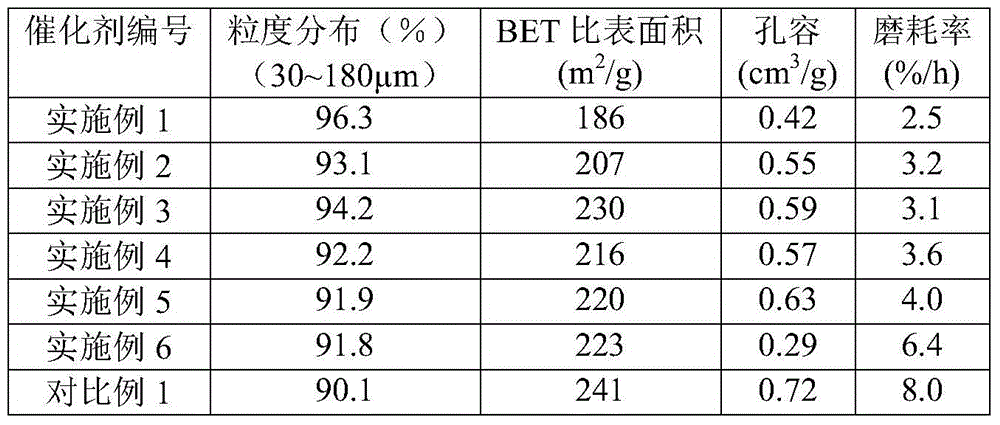

Examples

Embodiment 1

[0042] Weigh 50 kg of ferric nitrate nonahydrate, then add corresponding amount of copper nitrate and sodium metavanadate, add deionized water to dissolve, and obtain a mixed salt solution, in which the weight ratio Fe:V:Cu=100:0.39:3.6 , the molar concentration of iron ions in the mixed salt solution is 0.57mol / L.

[0043] Preheat the mixed salt solution to 65°C, dissolve 30kg of sodium carbonate and add deionized water to prepare a sodium carbonate solution with a concentration of 0.8mol / L as a precipitant, preheat the sodium carbonate solution to 70°C, and mix the mixed salt solution with The sodium carbonate solution is pumped into the reactor by a feed pump, and co-currently precipitated to obtain a mixed salt precipitation slurry. The temperature of the mixed salt precipitation slurry is kept at 68° C. and the pH value is always 6.7±0.5 throughout the co-current precipitation process.

[0044] The slurry is not aged, separated by a filter press, washed with deionized wa...

Embodiment 2

[0048] Weigh 40 kg of ferric nitrate nonahydrate, add corresponding amount of copper nitrate and sodium metavanadate, add deionized water to dissolve, and obtain mixed salt solution, the weight ratio of elements in the mixed salt solution is Fe:V:Cu=100:0.3 : 2.0, wherein the molar concentration of iron ions in the mixed salt solution is 0.09mol / L.

[0049] Preheat the mixed salt solution to 30°C, take 20kg of sodium carbonate to prepare a sodium carbonate solution with a concentration of 1.8mol / L as a precipitant, preheat the sodium carbonate solution to 30°C, and use the mixed salt solution and sodium carbonate solution The feed pump is pumped into the reactor, and the co-current precipitation is obtained to obtain the mixed salt precipitation slurry. The temperature of the mixed salt precipitation slurry is kept at 30° C. and the pH value is always 5.8 throughout the co-current precipitation process.

[0050]The mixed salt precipitation slurry was aged at 30°C for 5 hours,...

Embodiment 3

[0054] Weigh 70kg of ferric nitrate nonahydrate, add the corresponding amount of copper nitrate and sodium vanadate, add deionized water to dissolve, and obtain a mixed salt solution. The weight ratio of elements in the mixed salt solution is Fe:V:Cu=100:1.0 : 5.0, prepared as a mixed salt solution with an iron ion concentration of 1.42mol / L. Preheat the mixed salt solution to 60°C, dissolve 70kg of ammonium carbonate and add deionized water to prepare an ammonium carbonate solution with a concentration of 0.5mol / L as a precipitant, preheat the ammonium carbonate solution to 50°C, and mix the mixed salt solution with The ammonium carbonate solution is pumped into the reactor by a feed pump, and co-currently precipitated to obtain a mixed salt precipitation slurry. The temperature of the mixed salt precipitation slurry is kept at 60° C. and the pH value is always 8.6 throughout the co-current precipitation process.

[0055] The precipitated slurry was aged at 60° C. for 0.5 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com