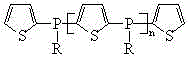

Alkylphosphine oligomer and synthesis method thereof

A synthesis method and oligomer technology are applied in the field of alkyl phosphine oligomers and their synthesis, which can solve the problems of low thermal stability, easy hydrolysis, poor acid and alkali resistance and solvent resistance, and achieve good carbon-forming ability. , Short reaction time, good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

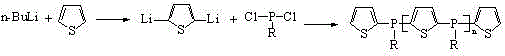

Method used

Image

Examples

Embodiment 1

[0029] 1) Connect a 2000mL four-neck flask to a mechanical stirrer and a constant pressure dropping funnel. Add 40.4 g of thiophene and 600 mL of solvent n-hexane into the four-neck flask. Cool the four-neck flask to -10°C and maintain it for 30min. At this temperature, n-butyl lithium in n-hexane (2.5M, 384mL) and 4.5g of tetramethylethylenediamine were slowly added dropwise from a constant pressure dropping funnel To the reaction flask, the dropwise addition time is 1.5h. With the addition of n-butyllithium, the temperature of the system rises spontaneously. After the dropwise addition, the temperature of the system was slowly raised to 40° C. and the reaction was stirred at this temperature for 2 h.

[0030] 2) Re-cool the four-neck flask to lower the system temperature to -5°C. Slowly drop 46.8 g of methylphosphine dichloride into the reaction flask through a constant pressure dropping funnel, and keep the temperature of the system not exceeding 20°C during the dropping...

Embodiment 2

[0036] 1) Connect a 2000mL four-neck flask to a mechanical stirrer and a constant pressure dropping funnel. Add 40.4 g of thiophene and 600 mL of solvent diethyl ether into the four-neck flask. Cool the four-neck flask to -20°C and maintain it for 30min. At this temperature, a cyclohexane solution of n-butyllithium (2.5M, 384mL) and 4.5g of tetramethylethylenediamine were slowly mixed through a constant pressure dropping funnel. Add it dropwise to the reaction flask, and the dropping time is 2.5h. With the addition of n-butyllithium, the temperature of the system rises spontaneously. After the dropwise addition, the temperature of the system was slowly raised to 30° C. and stirred at this temperature for 3 h.

[0037] 2) Re-cool the four-neck flask to lower the system temperature to -10°C. Slowly drop 52.4 g of ethyl phosphine dichloride into the reaction flask through a constant pressure dropping funnel, and keep the temperature of the system not exceeding 20° C. during th...

Embodiment 3

[0043] 1) Connect a 2000mL four-neck flask to a mechanical stirrer and a constant pressure dropping funnel. Add 40.4 g of thiophene and 600 mL of petroleum ether into the four-neck flask. Cool the four-neck flask to -10°C and maintain it for 30 minutes. At this temperature, diethyl ether solution (2.5M, 384mL) of n-butyllithium and 4.5g of N,N'-dimethylethylenediamine were mixed by constant pressure The dropping funnel was slowly added dropwise to the reaction flask, and the dropping time was 1.5h. With the addition of n-butyllithium, the temperature of the system rises spontaneously. After the dropwise addition, the temperature of the system was slowly raised to 40° C. and stirred at this temperature for 2 h.

[0044] 2) Re-cool the four-neck flask to lower the system temperature to -5°C. Slowly drop 58.0 g of n-propylphosphine dichloride into the reaction flask through a constant pressure dropping funnel, and keep the temperature of the system not exceeding 20°C during th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com