Supported metallocene catalyst for ethylene polymerization and its preparation method and application

A metallocene catalyst and ethylene polymerization technology, applied in the field of olefin polymerization catalysts, can solve the problems of limiting the industrial application of silica gel-loaded metallocene catalysts, low catalyst loading efficiency, and complicated carrier preparation, and achieve high ethylene polymerization catalytic activity, good shape, The effect of high bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

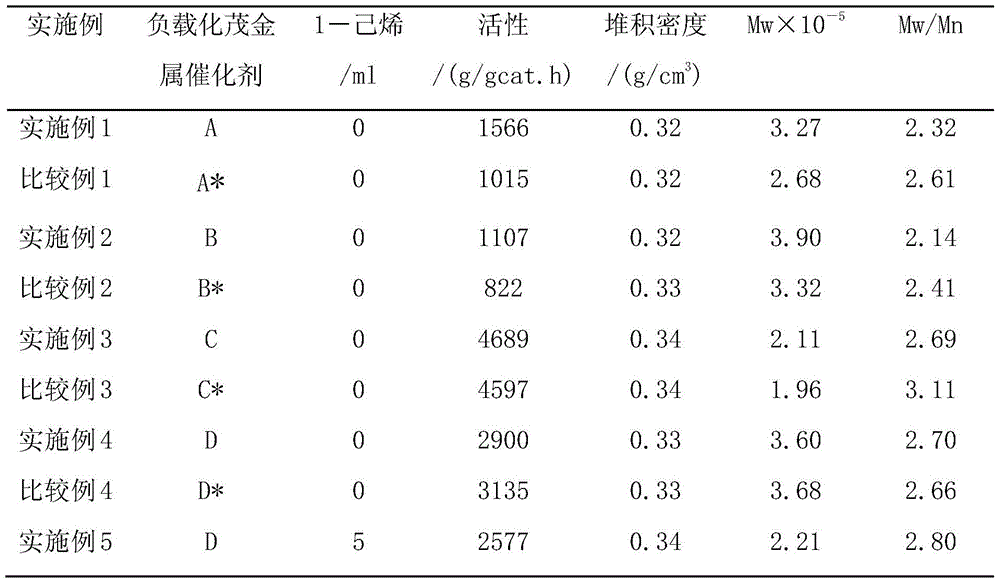

Examples

Embodiment 1

[0035] (1) Preparation of chlorinated hydrocarbyl silicon / silica gel support

[0036] Under the protection of nitrogen, take 5.5 grams of silica gel carrier and add 100 ml of dried hexane to disperse into a suspension, add 1 ml of SiCl 2 (n-Bu) 2 , start stirring, heat up to 30° C., react for 4 hours, and dry in vacuum to obtain a solid powder with good fluidity.

[0037] (2) Preparation of halogenated hydrocarbyl magnesium modified silica gel carrier

[0038] Under the protection of nitrogen, take 5.0 g of the modified silica gel carrier obtained in (1) and add it to a glass reactor, add 50 ml of dried toluene, disperse it into a suspension, add 5 ml of 1M ethylmagnesium chloride, start stirring, and heat up to React at 30°C for 4 hours and dry in vacuum to obtain a solid powder with good fluidity.

[0039] (3) Preparation of alkylaluminum / borate modified silica gel support

[0040] Under the protection of nitrogen, take 5.0 grams of the modified silica gel carrier obtain...

Embodiment 2

[0044] (1) Preparation of chlorinated hydrocarbyl silicon / silica gel support

[0045] Same as step (1) of Example 1.

[0046] (2) Preparation of halogenated hydrocarbyl magnesium modified silica gel carrier

[0047] Same as embodiment 1 step (2)

[0048] (3) Preparation of alkylaluminum / borate modified silica gel support

[0049] Same as embodiment 1 step (3)

[0050] (4) Preparation of supported metallocene catalyst B

[0051] With embodiment 1 step (4), only 0.129 gram (1,3-BuMeCp) in embodiment 1 2 ZrCl 2 Replaced with 0.156 g (1,3-BuMeCp) 2 HfCl 2 [Bis(1,3-butylmethylcyclopentadienyl) hafnium dichloride] to obtain supported metallocene catalyst B. Characterized by ICP, in catalyst B, the weight content of Hf is 0.91%, the weight content of Al is 7.84%, and the weight content of Mg is 2.33%.

Embodiment 3

[0053] (1), (2), (3) are the same as the preparation methods of (1), (2), and (3) in Example 1.

[0054] (4) Preparation of supported metallocene catalyst C

[0055] Same as step (4) of Example 1, only 0.129 grams of (1,3-BuMeCp) in Example 1 2 ZrCl 2 Replaced with 0.121 g of bis-(n-butylcyclopentadienyl)zirconium dichloride (nBuCp) 2 ZrCl 2 , to obtain the supported metallocene catalyst C. Characterized by ICP, in catalyst C, the weight content of Zr is 0.51%, the weight content of Al is 7.10%, and the weight content of Mg is 2.47%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com