A kind of supported metallocene catalyst for ethylene polymerization and its preparation method and application

A metallocene catalyst, a technology for ethylene polymerization, applied in the field of olefin polymerization catalysts, can solve the problems of limited industrial application, large amount of MAO, poor shape of carrier particles, etc., and achieve high ethylene polymerization catalytic activity, lower production costs, and good particle shape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

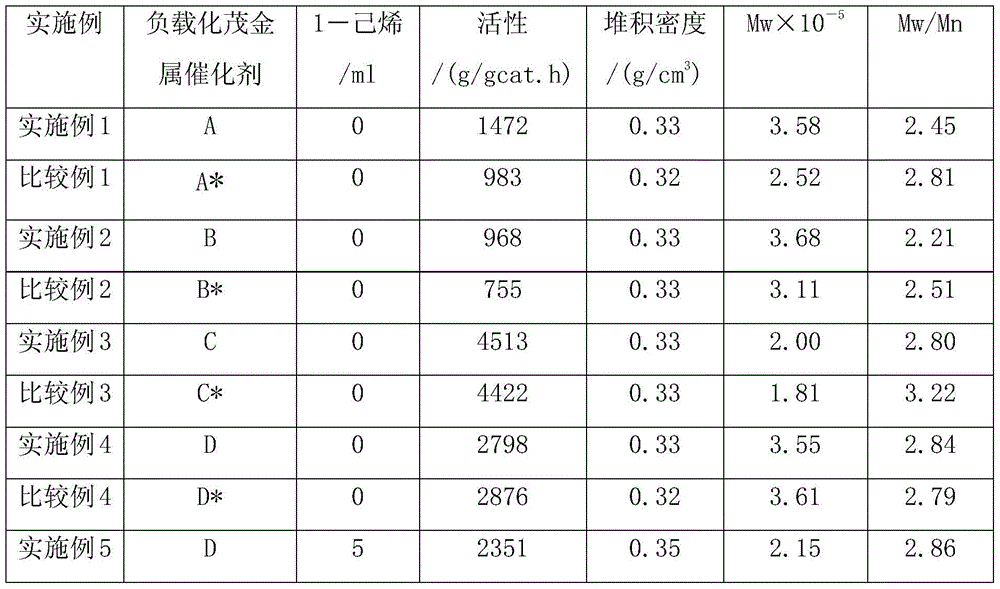

Examples

Embodiment 1

[0032] (1) Preparation of chlorinated hydrocarbyl silicon / silica gel support

[0033] Under the protection of nitrogen, take 5.5 grams of silica gel carrier and add 100 ml of dried hexane to disperse into a suspension, add 1 ml of SiCl 2 (n-Bu) 2 , start stirring, heat up to 30° C., react for 4 hours, and dry in vacuum to obtain a solid powder with good fluidity.

[0034] (2) Preparation of alkylaluminum / chlorinated hydrocarbyl silicon / borate / silica gel support

[0035] Under the protection of nitrogen, take 5.0 grams of the modified silica gel carrier obtained above and put it into a glass reactor, add 60 ml of dried toluene, disperse into a suspension, add 8 ml of 5 mmol / ml triisobutyl aluminum toluene solution, and heat up to 50° C., stirred and reacted for 4 hours, then washed three times with 60 ml×3 toluene, then washed with hexane, and dried in vacuum to obtain a solid powder with good fluidity. Take 3 grams of the above powder and add it to a glass reaction vessel u...

Embodiment 2

[0039] (1) Preparation of chlorinated hydrocarbyl silicon / silica gel support

[0040] Same as step (1) of Example 1.

[0041] (2) Preparation of alkylaluminum / chlorinated hydrocarbyl silicon / borate / silica gel support

[0042] Same as embodiment 1 step (2)

[0043] (3) Preparation of supported metallocene catalyst B

[0044] With embodiment 1 step (3), only 0.129 gram (1,3-BuMeCp) in embodiment 1 2 ZrCl 2 Replaced with 0.156 g (1,3-BuMeCp) 2 HfCl 2 [Bis(1,3-butylmethylcyclopentadienyl) hafnium dichloride] to obtain supported metallocene catalyst B. Characterized by ICP, in catalyst B, the weight content of Hf is 0.96%, and the weight content of Al is 7.91%.

Embodiment 3

[0046] (1) and (2) are the same as (1) and (2) preparation methods in Example 1.

[0047] (3) Preparation of supported metallocene catalyst C

[0048] Same as step (3) of Example 1, only 0.129 grams of (1,3-BuMeCp) in Example 1 2 ZrCl 2 Replaced with 0.121 g of bis-(n-butylcyclopentadienyl)zirconium dichloride (nBuCp) 2 ZrCl 2 , to obtain the supported metallocene catalyst C. Characterized by ICP, in catalyst C, the weight content of Zr is 0.53%, and the weight content of Al is 7.22%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com