High-voltage-insulation sealing adhesive

A high-voltage insulation and glue blocking technology, which is applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of unsightly, time-consuming and labor-intensive, and poor results, and achieve simple and convenient use, Excellent flame retardancy, strong random effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

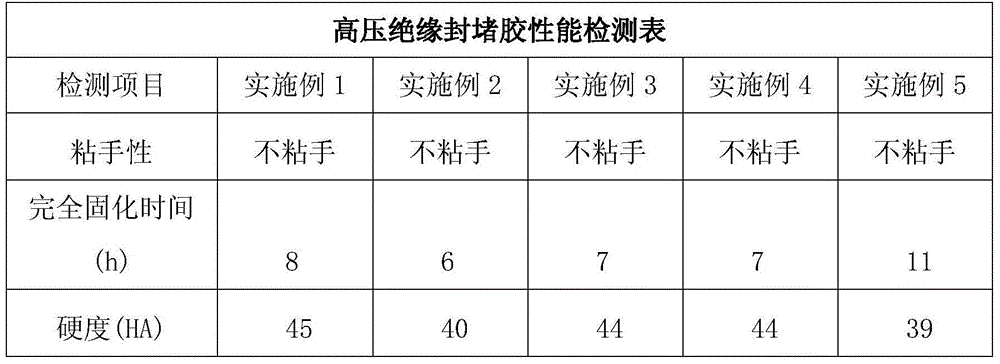

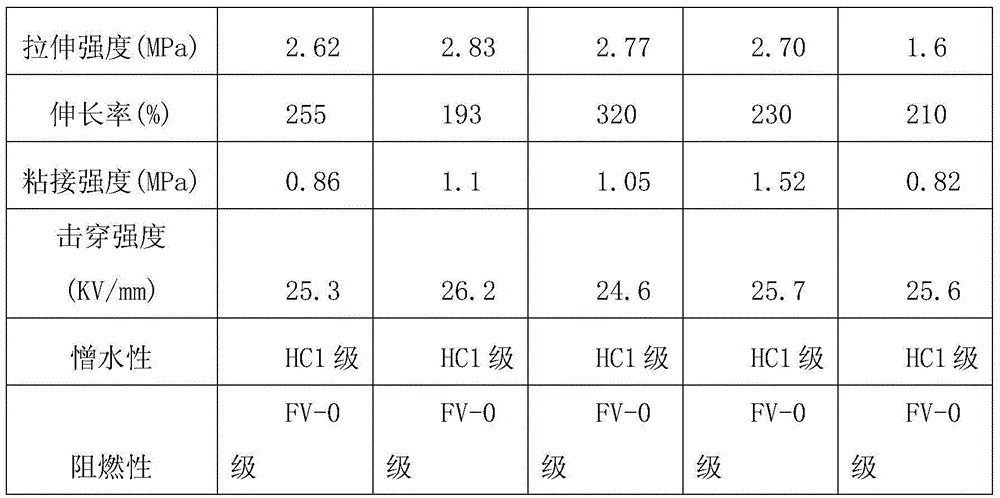

Examples

Embodiment 1

[0020] The first composition: 45 parts of 20000cP hydroxyl-terminated polysiloxane, 1.5 parts of tetraethyl orthosilicate and 0.5 part of aminosilane coupling agent were mixed and stirred evenly, and then 6 parts of silicon dioxide, 4 parts of zinc stearate 12 parts of nano-bentonite, 6 parts of decabromodiphenylethane, and 25 parts of aluminum hydroxide were added to the kneader, stirred evenly, and finally extruded into blocks and packaged.

[0021] The second composition: Mix and stir 40 parts of 20000cP hydroxyl-terminated polysiloxane, 5 parts of 200cP dimethyl silicone oil and 0.4 part of dibutyltin dilaurate, and then add 4 parts of zinc stearate and 10 parts of nano-bentonite , 9.6 parts of decabromodiphenylethane and 25 parts of aluminum hydroxide were added into the kneader, stirred evenly, and finally extruded into blocks and packaged.

[0022] The above-mentioned first composition and second composition are made into blocks with the same length, width and height, a...

Embodiment 2

[0024] The first composition: 45 parts of 5000cP hydroxyl-terminated polysiloxane, 1.5 parts of tetraethyl orthosilicate and 0.5 parts of aminosilane coupling agent were mixed and stirred evenly, and then 10 parts of silicon dioxide, 4 parts of zinc stearate 12 parts of nano-bentonite, 7 parts of decabromodiphenylethane, and 20 parts of aluminum hydroxide are added to the kneader, stirred evenly, and finally extruded into blocks and packaged.

[0025] The second composition: 40 parts of 5000cP hydroxyl-terminated polysiloxane, 5 parts of 200cP dimethicone and 0.4 part of dibutyltin dilaurate were mixed and stirred evenly, and then 4 parts of zinc stearate and 12 parts of nano-bentonite , 7 parts of decabromodiphenylethane, and 20 parts of aluminum hydroxide were added into the kneader, stirred evenly, and finally extruded into blocks and packaged.

[0026] The above-mentioned first composition and second composition are made into blocks with the same length, width and height, ...

Embodiment 3

[0028] The first composition: Mix and stir 11.25 parts of 50000cP hydroxyl-terminated polysiloxane, 33.75 parts of 10000cP hydroxyl-terminated polysiloxane, 1.5 parts of tetraethyl orthosilicate and 0.5 parts of aminosilane coupling agent, and then Add 8 parts of silicon dioxide, 4 parts of zinc stearate, 10 parts of nano-bentonite, 6 parts of decabromodiphenylethane, and 25 parts of aluminum hydroxide into the kneader, stir evenly, and finally extrude into a block and package .

[0029] The second composition: 10 parts of 50000cP hydroxyl-terminated polysiloxane, 30 parts of 10000cP hydroxyl-terminated polysiloxane, 5 parts of 200cP dimethicone and 0.4 part of dibutyltin dilaurate were mixed and stirred evenly, and then the Add 4 parts of zinc stearate, 9.6 parts of nano-bentonite, 6 parts of decabromodiphenylethane, and 25 parts of aluminum hydroxide into a kneader, stir evenly, and finally extrude into blocks and package them.

[0030] The above-mentioned first composition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com