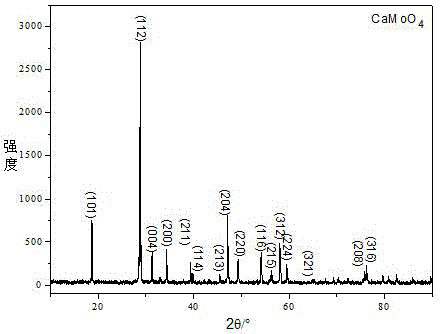

Preparation method of spherical fluorescent powder

A fluorescent powder and spherical technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of LED chip matching, environmental pollution, and unsatisfactory stability, and achieve the effect of simple preparation method and high color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

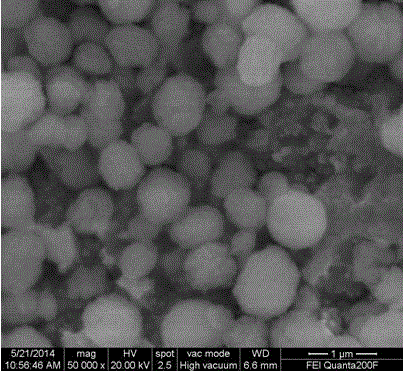

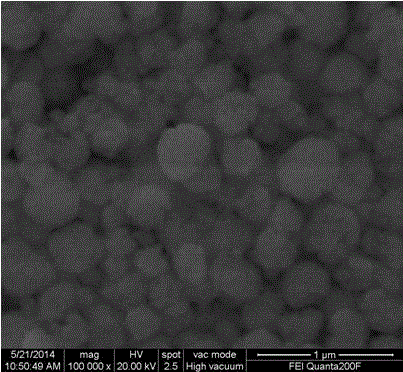

Image

Examples

Embodiment 1

[0018] (1) Weigh calcium nitrate and ammonium molybdate tetrahydrate according to the molar ratio of the product molecular formula and dissolve them in appropriate amount of distilled water respectively, then weigh europium trioxide according to the 1% molar ratio of the product and dissolve them with dilute nitric acid, and Heat to remove excess nitric acid, then dissolve with appropriate amount of distilled water.

[0019] (2) Mix the three solutions in step (1), and add ethanol or isopropanol in a proportion of 60% of the volume of the mixed solution, stir vigorously, and then, press dodecyltrimethylammonium bromide (CTAB ) with Ca 2+ The ratio of ions is 0.2:1. Weigh dodecyltrimethylammonium bromide and add it to the above solution, and continue stirring until uniform.

[0020] (3) Transfer the mixture in step (2) into a reaction kettle, and react for 24 hours at 180°C.

[0021] (4) After the reactor is cooled, wash the precipitate three times with distilled water and et...

Embodiment 2

[0023] (1) Weigh calcium nitrate and ammonium molybdate tetrahydrate according to the molar ratio of the product molecular formula and dissolve them in appropriate amount of distilled water, then weigh europium trioxide to dissolve with dilute nitric acid according to the 5% molar ratio of the product, and Heat to remove excess nitric acid, then dissolve with appropriate amount of distilled water.

[0024] (2) Mix the three solutions in step (1), and add ethanol or isopropanol in a proportion of 30% of the volume of the mixed solution, stir vigorously, and then press dodecyltrimethylammonium bromide (CTAB ) with Ca 2+ The ratio of ions is 0.5:1. Weigh dodecyltrimethylammonium bromide and add it to the above solution, and continue stirring until uniform.

[0025] (3) Transfer the mixture in step (2) into a reaction kettle, and react for 12 hours at 190°C.

[0026] (4) After the reactor is cooled, wash the precipitate three times with distilled water and ethanol, and dry the p...

Embodiment 3

[0028] (1) Weigh calcium nitrate and ammonium molybdate tetrahydrate according to the molar ratio of the product molecular formula and dissolve them in appropriate amount of distilled water, then weigh europium trioxide to dissolve with dilute nitric acid according to the 2.5% molar ratio of the product, and Heat to remove excess nitric acid, then dissolve with appropriate amount of distilled water.

[0029] (2) Mix the three solutions in step (1), add ethanol or isopropanol at a ratio of 45% of the volume of the mixed solution, stir vigorously, and then press dodecyltrimethylammonium bromide (CTAB ) with Ca 2+ The ratio of ions is 0.3:1. Weigh dodecyltrimethylammonium bromide and add it to the above solution, and continue stirring until uniform.

[0030] (3) Transfer the mixture in step (2) into a reaction kettle, and react for 20 hours at 170°C.

[0031] (4) After the reactor is cooled, wash the precipitate three times with distilled water and ethanol, and dry the precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com