Hydrofining process of waste lubricating oil

A hydrorefining and waste lubricating oil technology, which is applied in the fields of gasoline and diesel blending combination and lubricating oil base oil, can solve the problems of high equipment and operation costs, complicated process, etc., reduce the accumulation of colloid, increase the contact area, and better The effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

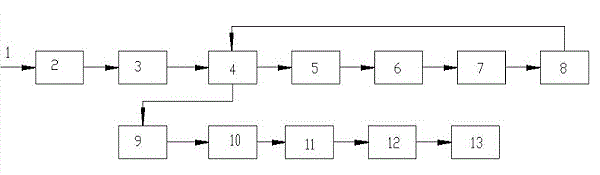

[0027] The raw material waste lubricating oil 1 (see Table 1 for its properties) is first filtered through the dehydration and impurity removal unit 2 to filter out large particles of impurities larger than 25 μm, and remove the moisture in the raw material, and then enter the weight removal and fractionation device 3 to remove Removal of colloid and asphalt, deweighting adopts the method of propane extraction; then heat exchange with the material flowing out of the dechlorination reactor 8 through the heat exchanger 4, and then heated to 310°C by the heater 5 and enters the prehydrogenation reactor 6 , at a pressure of 6.0MPa, a volume ratio of hydrogen to oil of 300, and a volumetric space velocity of 1h -1Under certain conditions, various metal impurities are removed and some olefins are saturated. The upper part of the prehydrogenation reactor is filled with 1 / 3 volume of hydrogenation protection agent. The hydrogenation protection agent uses spherical Al-Ti-HY with large p...

Embodiment 2

[0029] Raw material waste lubricating oil 1 (see Table 1 for its properties) is first filtered and removed by dehydration and impurity removal device 2 to filter out large particles of impurities larger than 25 μm and remove moisture in the raw material, and then enter the weight removal and fractionation device 3 to remove In addition to colloid and asphalt, deweighting adopts the method of propane extraction; after heat exchange with the material flowing out of the dechlorination reactor 8 through the heat exchanger 4, it is heated to 330 ° C by the heater 5 and enters the prehydrogenation reactor 6 , at a pressure of 8.0MPa, a volume ratio of hydrogen to oil of 200, and a volumetric space velocity of 2h -1 Under certain conditions, various metal impurities are removed and some olefins are saturated. The upper part of the prehydrogenation reactor is filled with 1 / 3 volume of hydrogenation protection agent. The hydrogenation protection agent uses spherical Al-Ti-HY with large ...

Embodiment 3

[0031] Raw material waste lubricating oil 1 (see Table 1 for its properties) is first filtered and removed by dehydration and impurity removal device 2 to filter out large particles of impurities larger than 25 μm and remove moisture in the raw material, and then enter the weight removal and fractionation device 3 to remove Colloid and asphalt are removed, and weight removal adopts the method of wiped film evaporation; after heat exchange with the material flowing out of the dechlorination reactor 8 through the heat exchanger 4, it is heated to 360°C by the heater 5 and then enters the prehydrogenation reactor 6 , at a pressure of 12.0MPa, a volume ratio of hydrogen to oil of 100, and a volumetric space velocity of 3h -1 , to remove various metal impurities and saturate some olefins, the upper part of the prehydrogenation reactor is filled with 1 / 3 volume of hydrogenation protection agent, the hydrogenation protection agent uses spherical Al-Ti-HY with large pores as the carrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com