Roadway support method for preventing rock burst

A roadway support and rockburst technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problem that the support body is easy to be crushed, fractured and broken, the overall large deformation of the anchor body, and the support process To reduce the engineering volume of roadway support, simplify the production and enhance the effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

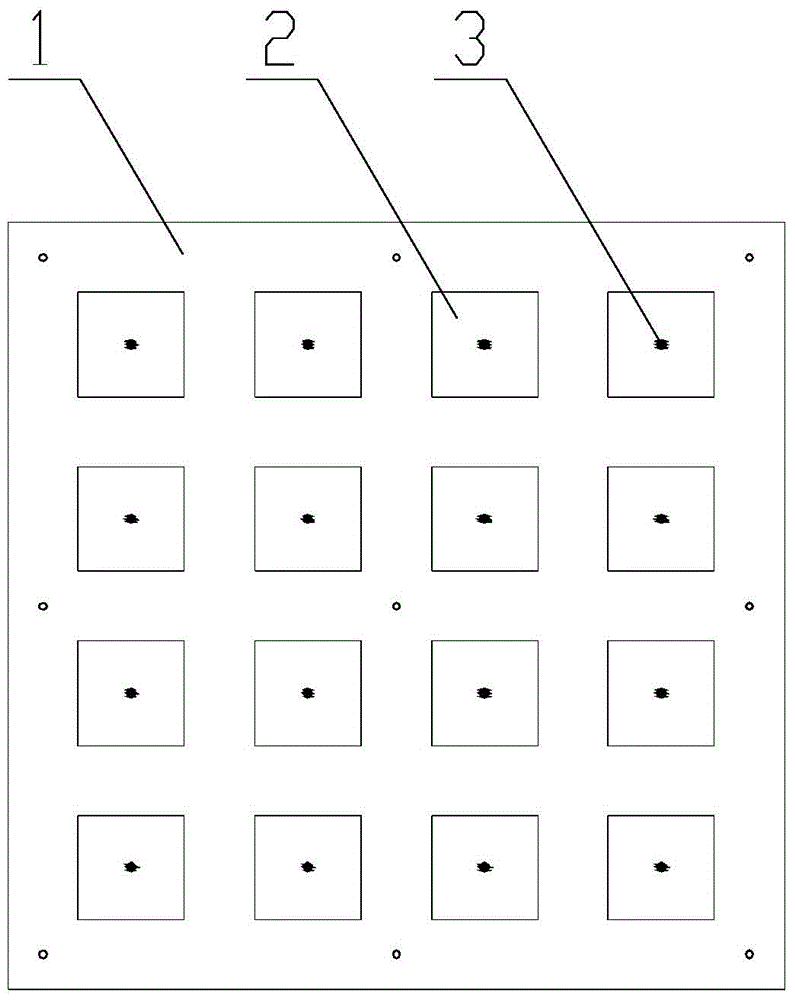

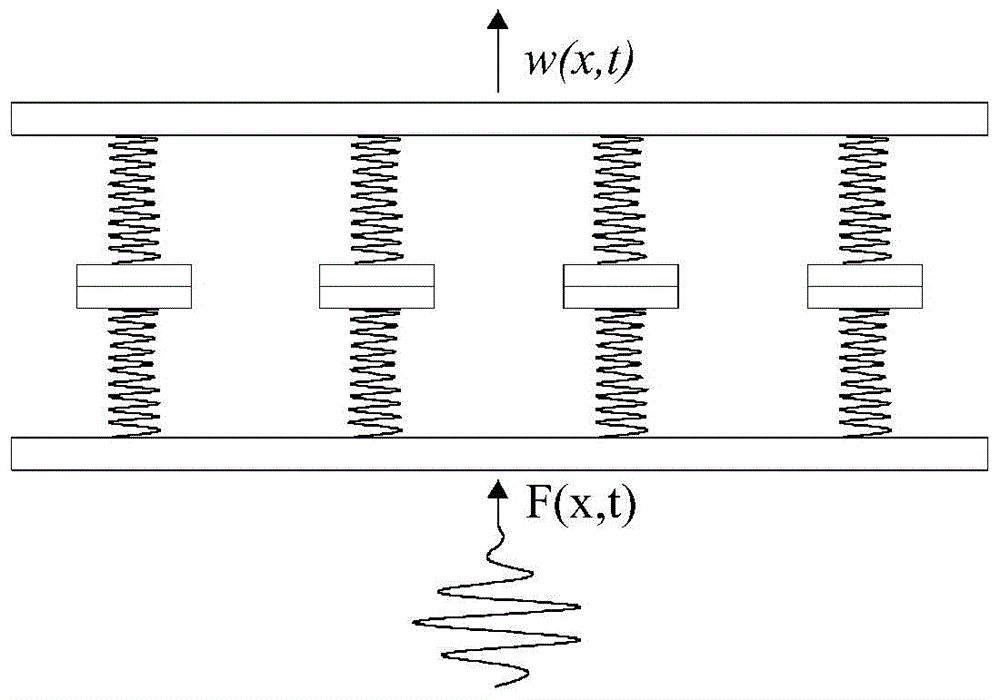

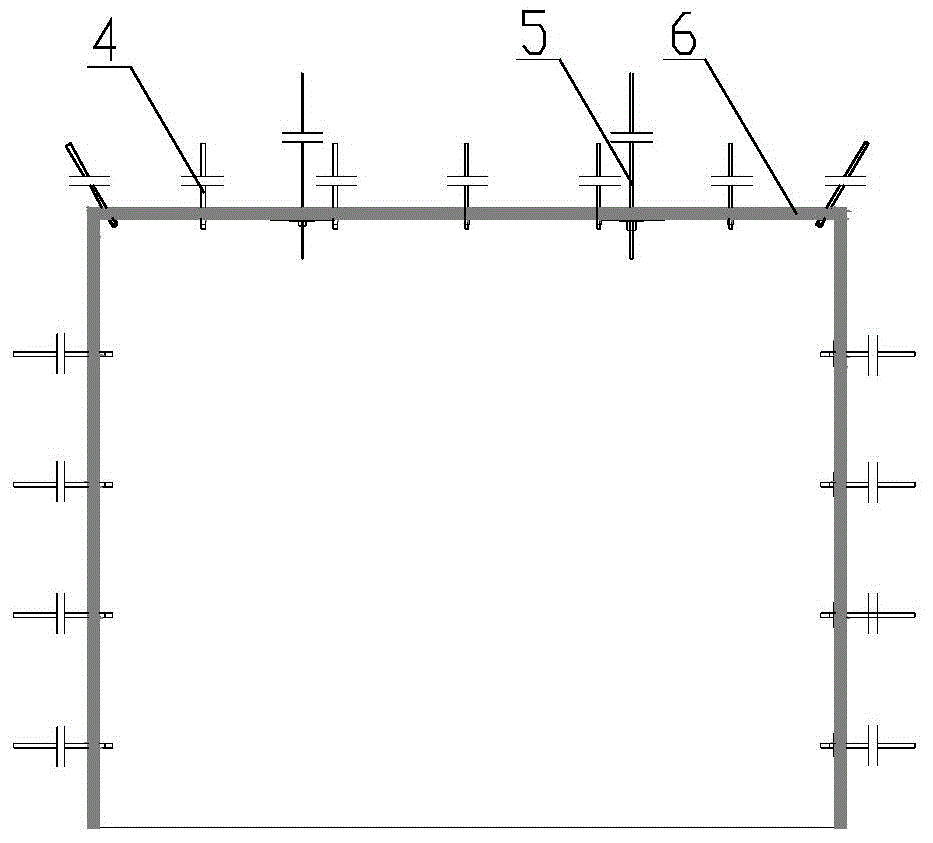

[0031] The present invention will be further described below in conjunction with accompanying drawing.

[0032] A roadway support method for preventing rock burst, comprising the following steps:

[0033] a. According to the mine seismic signals of different energy levels measured in the mine, the vibration frequency range of the coal mine underground is obtained; the vibration frequency range of the coal mine underground is measured by the microseismic monitoring system. Microseismic monitoring is to monitor the vibration generated by the deformation and rupture of rock mass, automatically record and save the waveform data of the microseismic time to obtain the vibration frequency downhole. The microseismic monitoring system is mainly divided into three parts, namely sensors, data collectors, time synchronization, data communication, and servers. The sensor converts formation motion (formation velocity or acceleration) into a measurable electrical signal. Non-seismic sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com