Axisymmetric comb-shaped inner fin structure and fin tube thereof

An inner fin and axisymmetric technology, which is applied in the engineering application field of heat transfer, can solve the problem of not being able to realize the uniform maximization of the temperature in the heat transfer process of the flow cross section, not being able to obtain the cooling of the fin's low-temperature surface, and destroying the radial distribution mode of the airflow temperature and other issues, to achieve the effect of improving product competitiveness, simple structure, and convenient processing and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in more detail below in conjunction with the accompanying drawings.

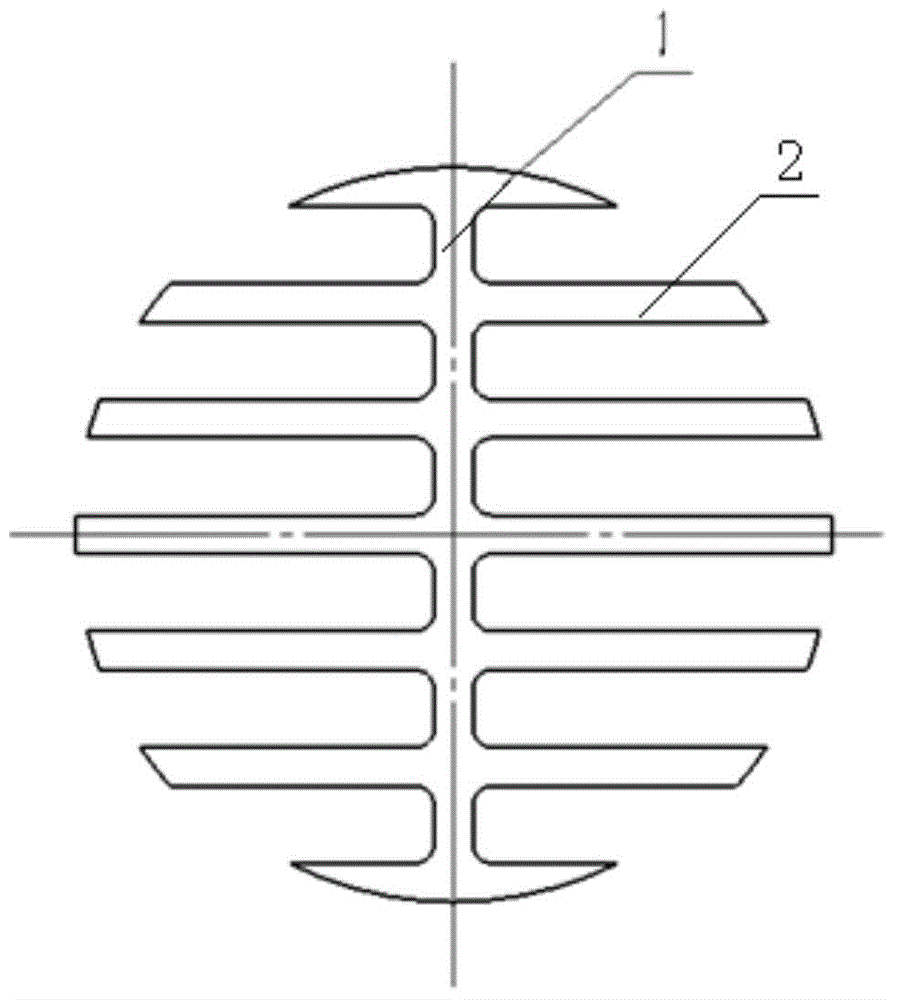

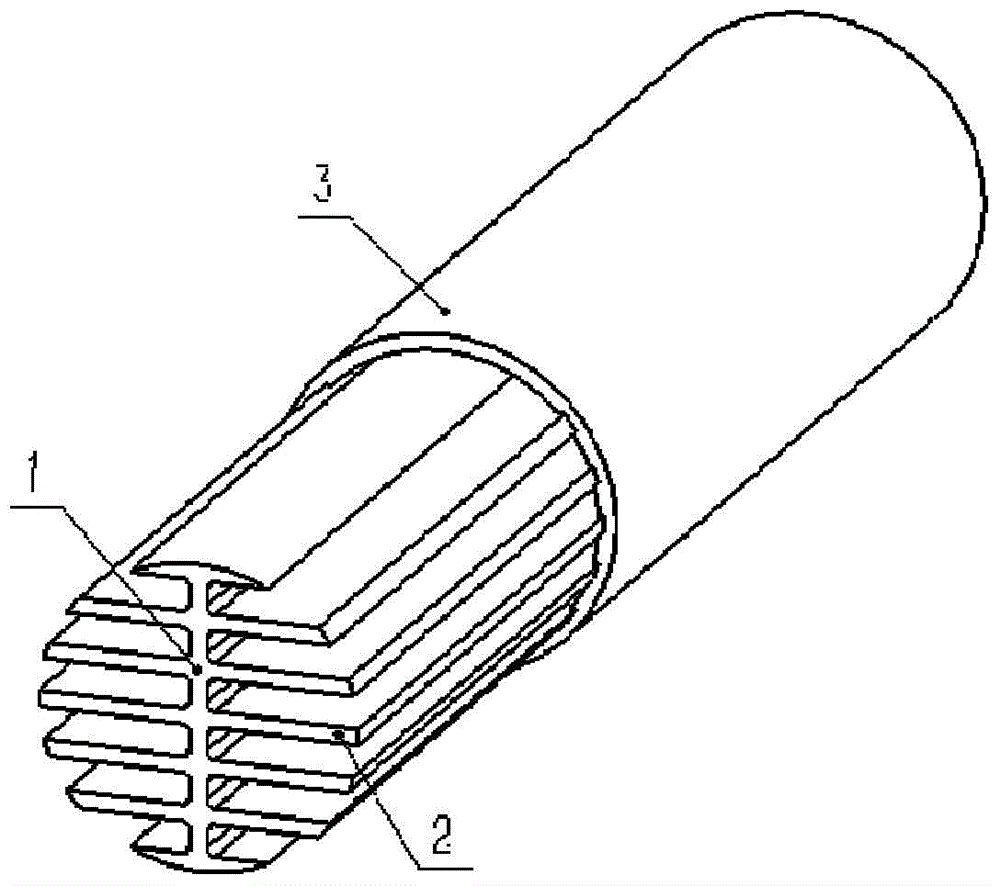

[0034] Such as figure 1 As shown, the present invention is an axisymmetric comb-shaped inner fin structure, which is composed of a central rib 1 and a plurality of sets of inner fin pairs vertically arranged on the central rib 1 integrally formed with the central rib 1, and each set of inner fins The pair consists of two inner fins 2 distributed axially symmetrically along the central rib 1 .

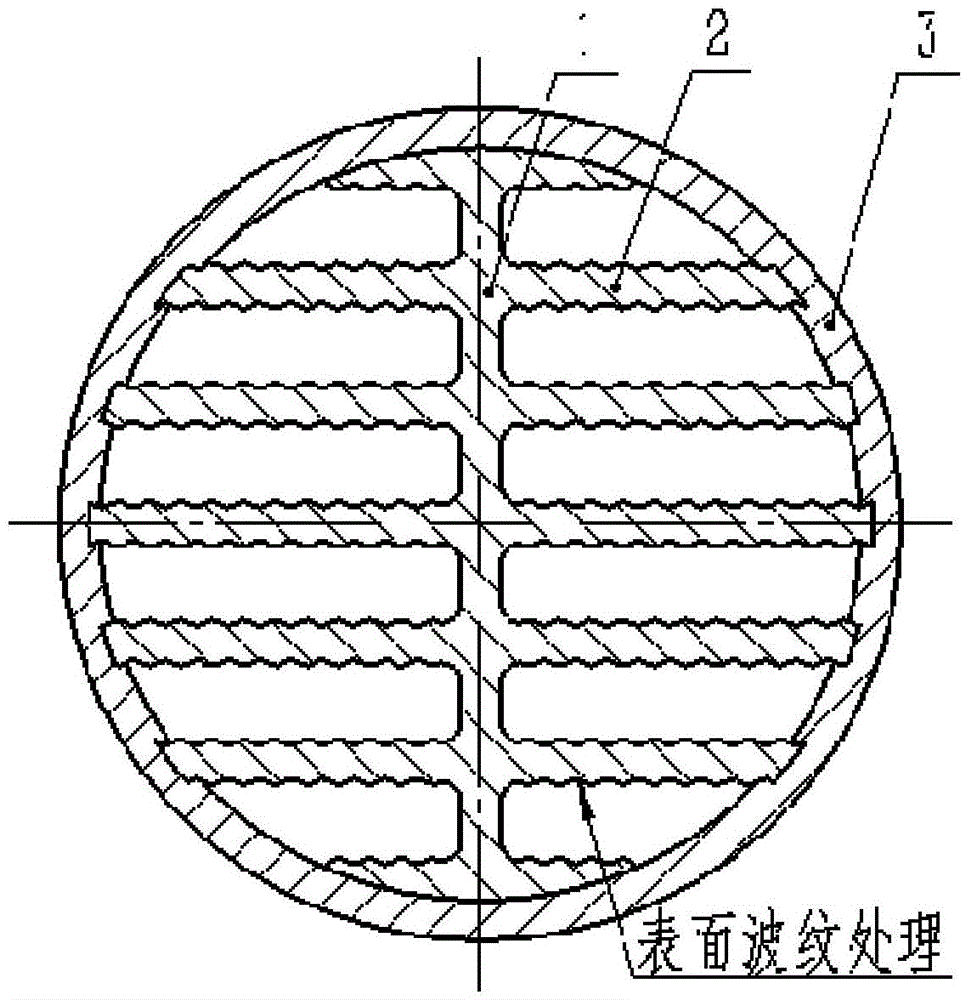

[0035] As a preferred embodiment of the present invention, the surface of the inner fin 2 is longitudinally corrugated, and the corrugation form is a zigzag, rectangular or sinusoidal function waveform, so that the overall heat transfer area is further increased on the original, and greatly enhanced The fluid disturbance is reduced, and the heat and mass transfer effect is improved. Such as image 3 Shown is a schematic cross-sectional view of the surface of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com