Novel flavour compositions with improved flavour and/or flavour shelf-life

A fragrance composition and fragrance technology, applied in food science, dough processing, food ingredients as odor improvers, etc., can solve problems such as fragrance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

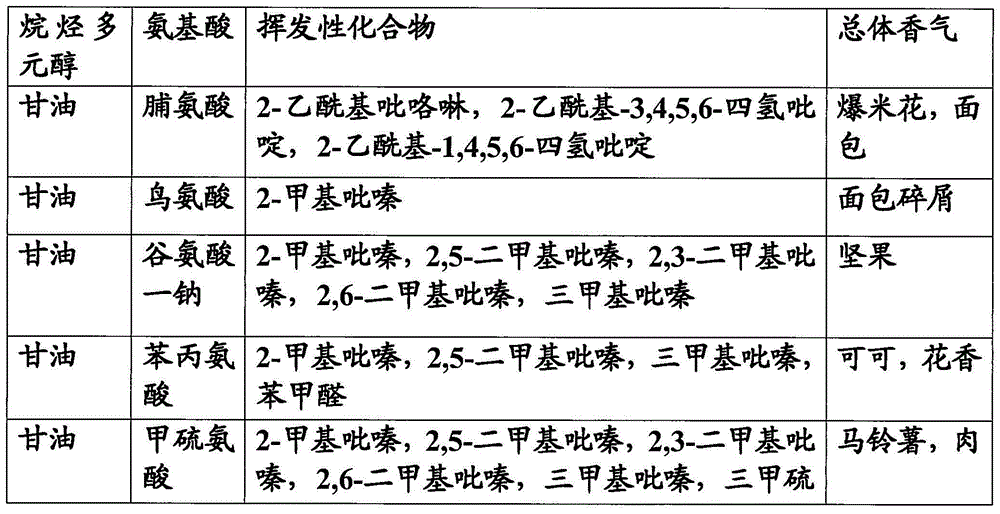

[0105] Example 1: Fragrance Compositions of the Invention Comprising Different Types of Amino Acids, Glycerin and Water

[0106] method

[0107] For the production of 45 exemplified by the amino acid proline gThe preparation method of the fragrance composition of the present invention: a mixture of proline (1.098g), glycerol (37.314g) and Vittel water (6.579g) was mechanically stirred at room temperature for 2h in a round bottom flask, and then preheated at 120°C. Heat in a hot oil bath for 2h.

[0108] Analytical method

[0109] The fiber (SPME Fiber PDMS-DVB 65 μm 23 gauge needle, Supelco N° 57345-U) was exposed to the headspace above the sample for 10 min at 30°C for 10 min at 30°C. After sampling, the fiber was transferred into the syringe hole in splitless mode for 5 min at 250°C to desorb and transfer the volatile compounds to the chromatography column. A 0.75mm i.d. sleeve (Supelco) was fitted to the syringe. Gas chromatography (GC) separation was performed using a...

Embodiment 2

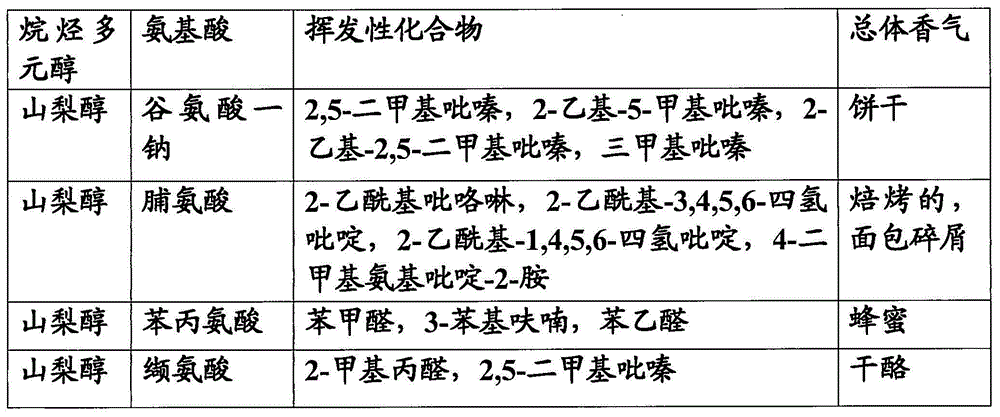

[0116] Example 2: Fragrance Compositions of the Invention Comprising Different Types of Amino Acids, Sorbitol and Water

[0117] method

[0118] Preparation method for producing 4.1 g of the fragrance composition of the present invention exemplified by the amino acid monosodium glutamate: a mixture of monosodium glutamate (0.1 g), sorbitol (3.4 g) and Vittel water (0.6 g) in The round bottom flask was stirred mechanically at room temperature for 2 h, then heated in a preheated oil bath at 120 °C for 2 h.

[0119] Analytical method

[0120] The method described in Example 1 was applied.

[0121] aroma quality

[0122] The fragrance compositions were sensory evaluated as described in Example 1 by a panel of 5-10 members. Analyze and feel the results

[0123] Volatile analysis and specific sniffing were performed as described above. The results are shown in Table 2.

[0124] Table 2

[0125]

Embodiment 3

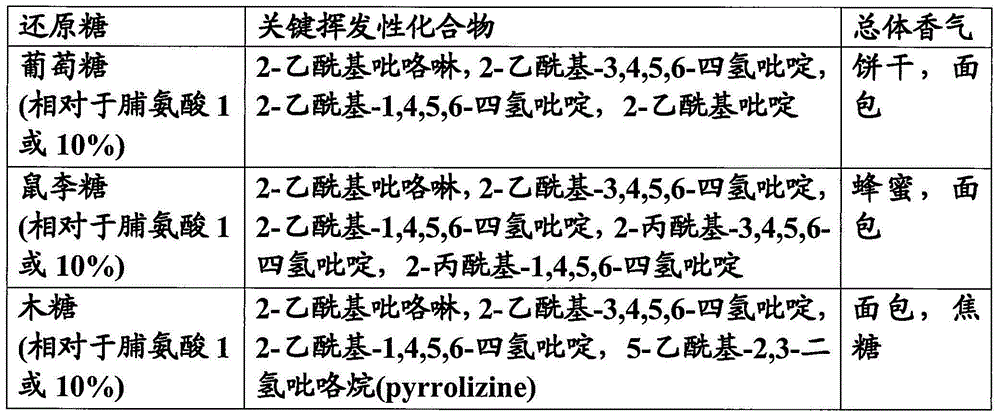

[0126] Example 3: Flavor compositions of the invention comprising different types of reducing sugars

[0127] method

[0128] The preparation method for producing 4.1 g of the fragrance composition of the present invention exemplified by the reducing sugar glucose: a mixture of proline (100.2 mg), glycerol (3409 mg), glucose (10.1 mg) and Vittel water (600 mg) was placed in a round bottom The flask was stirred mechanically at room temperature for 2 h, then heated in a preheated oil bath at 120° C. for 2 h.

[0129] Analytical method

[0130] The method described in Example 1 was applied.

[0131] aroma quality

[0132] The fragrance compositions were sensory evaluated as described in Example 1 by a panel of 3-6 members.

[0133] Analyze and feel the results

[0134] Volatile analysis and specific sniffing were performed as described above. The results are shown in Table 3.

[0135] table 3

[0136]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com