Patents

Literature

30 results about "Ornithine-Oxo-Acid Transaminase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pyridoxal phosphate enzyme that catalyzes the formation of glutamate gamma-semialdehyde and an L-amino acid from L-ornithine and a 2-keto-acid. EC 2.6.1.13.

Method for preparing L-ornithine-L aspartate

ActiveCN101798275AImprove pass rateReduce productionOrganic compound preparationAmino-carboxyl compound preparationActivated carbonChemistry

The invention discloses a method for preparing L-ornithine-L aspartate, which has the characteristics of taking L-ornithine acetate as a raw material and reacting the L-ornithine acetate with L-aspartate in water. The method particularly comprises the following steps of: dissolving the L-ornithine acetate in the water; adding the L-aspartate into the solution; regulating a pH value of the solution to be between 6 and 9 with ammonia; adding activated carbon for de-coloring and filtering; adding a reasonable amount of ethanol or methanol into a filtrate for stirring and crystallizing; and filtering and drying the filtrate to obtain the finished product. The method has the advantages of overcoming the defects existing in the prior art by using the property that ammonium acetate is easy to dissolve in the aqueous solution of alcohol, and also has the advantages of high yield, moderate reaction conditions, simple operation, stable product quality and the like.

Owner:福安药业集团重庆博圣制药有限公司

Bifidobacteria viable bacteria preparation and special-purpose protective agent thereof

ActiveCN101016527ASolve the problem of difficult storage at room temperatureSimple methodBacteriaVitamin CActive agent

The invention discloses a preparing method of bifidobacteria bacterial active agent and single-purpose protecting agent, which is characterized by the following: allocating 0.01-5.0 wt glycerin, 0.1-6.0 wt polyvinyl pyrrolidon, 0.1-5.0 carbowax, 1.0-10.0 wt skimmed milk powder, 0.5-15.0 wt mycose, 0.1-5.0 wt glutavene, 0.1-5.0 wt L-aspartic acid, 0.1-5.0 wt vitamin C sodium and 0.1-5.0 wt ornithine hydrochlorate. This invention solves the problem of preservation difficulty at normal temperature with conventional method.

Owner:LIVZON PHARM GRP INC

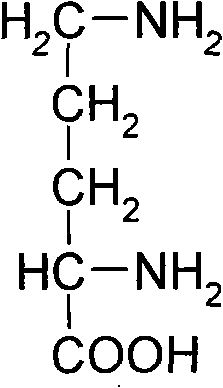

Method for producing L-ornithine by microorganism fermentation

InactiveCN101323866AFast acid productionImprove sugar conversion rateBacteriaMicroorganism based processesSolubilityChemical treatment

The invention provides a method for producing L-ornithine by microbial fermentation, namely, using Corynebacterium glutamate to obtain the strains of CS-189(cit<(-)>+SG<r>) by chemical treatment, and obtain the L-ornithine hydrochloride by fermentation, culture solution micro-filtration by a ceramic membrane, ion exchange resin and extraction by a hydrothermal crystallization method with decompression concentration. The strains used in the method are auxotrophy resistant to sulfaguanidine, which significantly enhances acid yield by fermentation. Meanwhile, aiming at the problem that the solubility of the L-ornithine hydrochloride in water is extremely difficult, the hydrothermal crystallization method is adopted to obtain better extraction rate under the condition that flammable and explosive alcohol is not used. The method simplifies processes and reduces extraction cost.

Owner:上海聚瑞生物技术有限公司

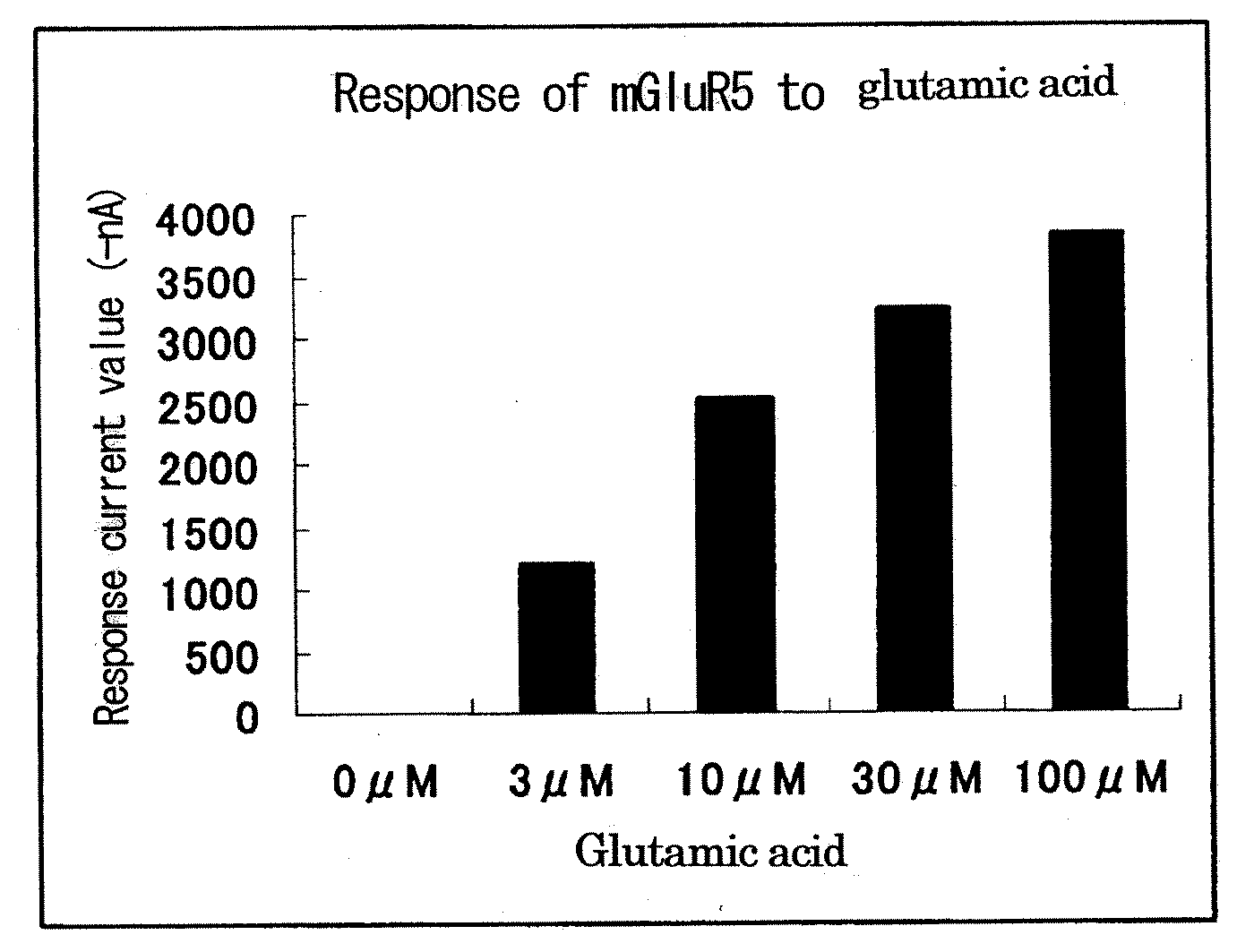

Metabotropic glutamate receptor activator

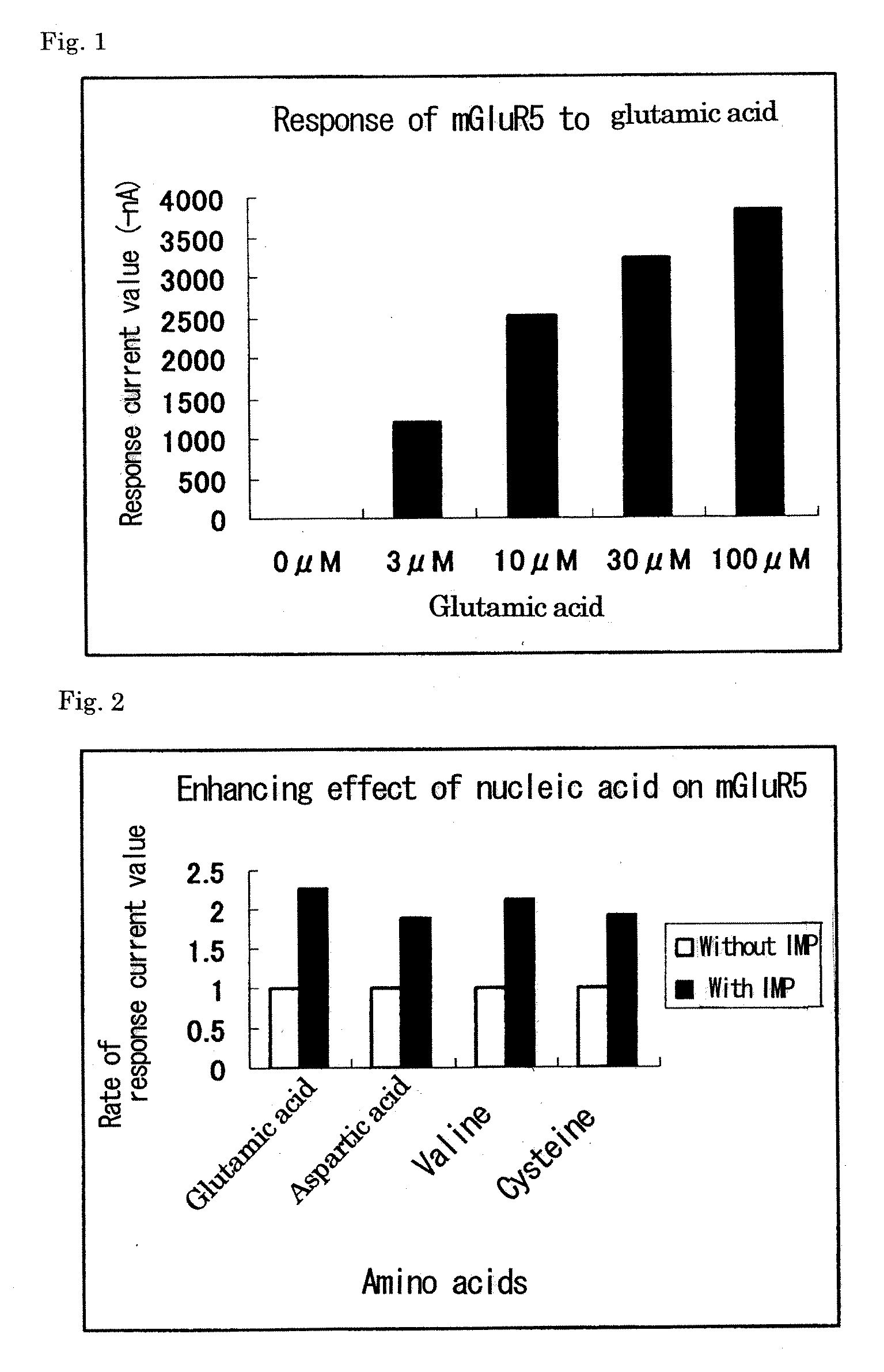

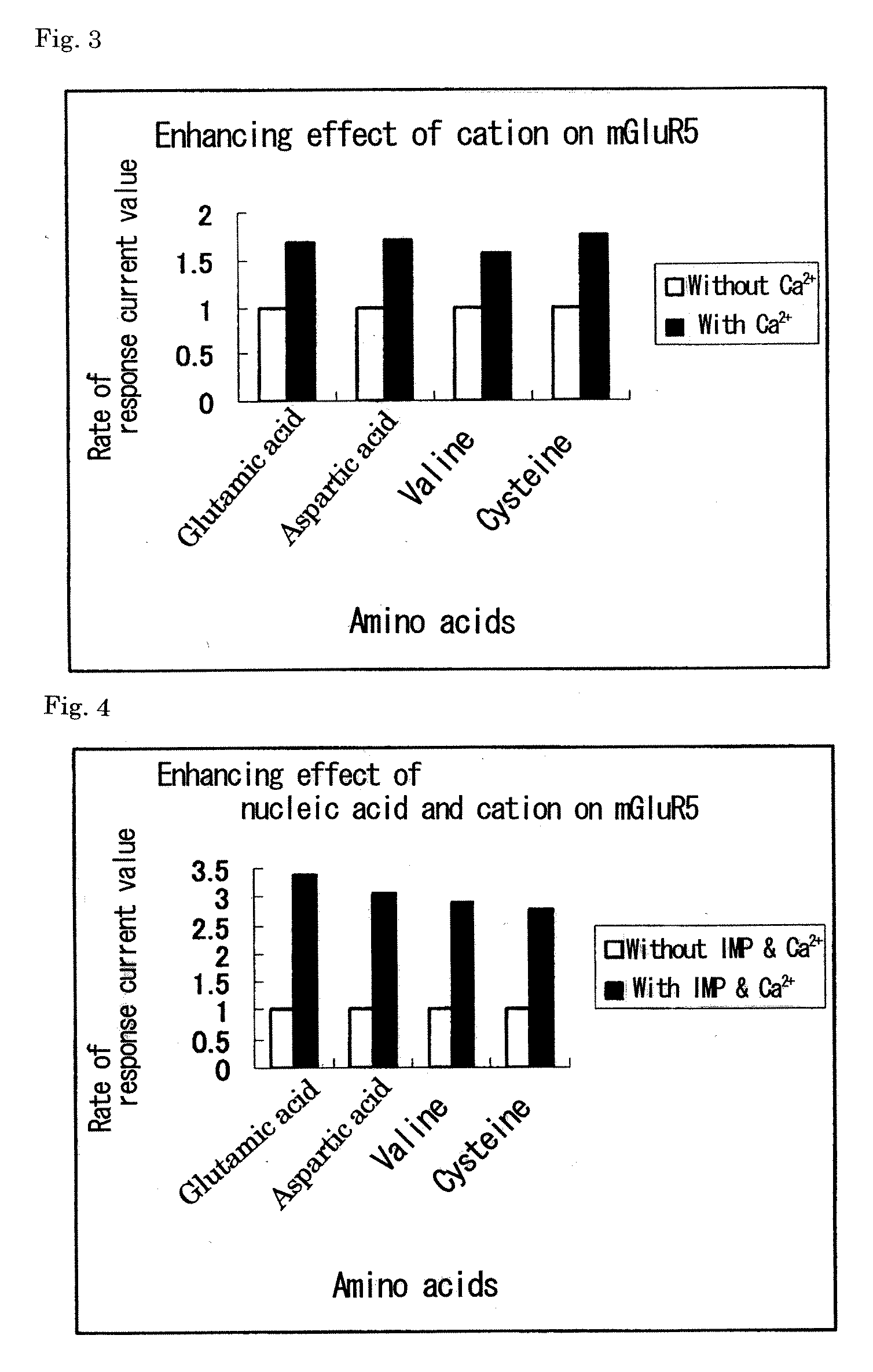

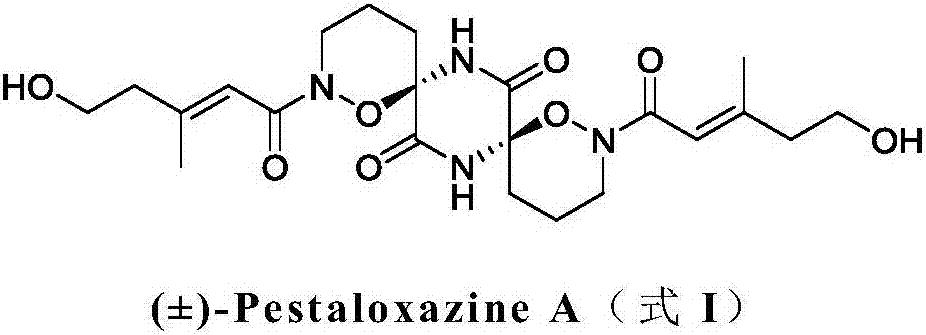

InactiveUS20080182811A1Raise security concernsHighly safe for a living bodyBiocideSenses disorderTryptophanValine

Amino acids other than glutamic acid are used as a metabotropic glutamate receptor activator. More preferably, aspartic acid, valine and cysteine are used as a group I metabotropic glutamate receptor activator; alanine, arginine, asparagine, aspartic acid, cysteine, glutamine, glycine, histidine, isoleucine, leucine, lysine, methionine, phenylalanine, proline, serine, threonine, tryptophan, tyrosine, valine, ornithine, taurine and hydroxyproline are used as a group II metabotropic glutamate receptor activator; and cysteine is used as a group III metabotropic glutamate receptor activator.

Owner:AJINOMOTO CO INC

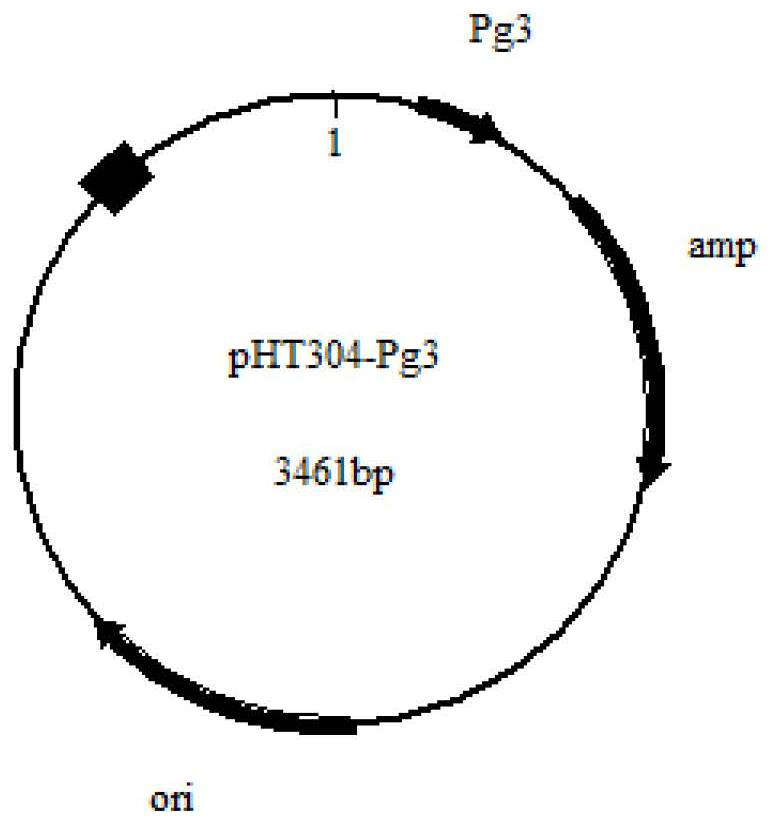

Signal peptide and application thereof in synthesis of l-arginine from conjac powder and value enhancement of conjac powder

ActiveUS20180258385A1Promote cell growthEfficient productionBacteriaPeptidesΒ mannanaseL-ornithine L-aspartate

The present invention relates to application of a novel signal peptide in L-arginine and its derivatives production from konjac powder, which belongs to the field of gene engineering, enzyme engineering and metabolism engineering. The present invention fused the signal peptide set forth in SEQ ID NO.1 with the β-mannanase of Bacillus subtilis CCTCC M 209200, and expressed the fused gene in the strain with high L-arginine yield. The recombinant strain Corynebacterium crenatum CGMCC 0890 / p MSPman had advantages on utilizing cheaper konjac powder as substrate, and after fermenting for 96 hours in a 5 L bioreactor, the L-arginine yield reached 45 g / L. Another two recombinant strains were constructed based on Corynebacterium crenatum CGMCC 0890 / pMSPman, and after fermenting for 96 hours in a 5 L bioreactor, the L-ornithine yield and L-citrulline reached 23.5 g / L and 26.3 g / L respectively.

Owner:JIANGNAN UNIV

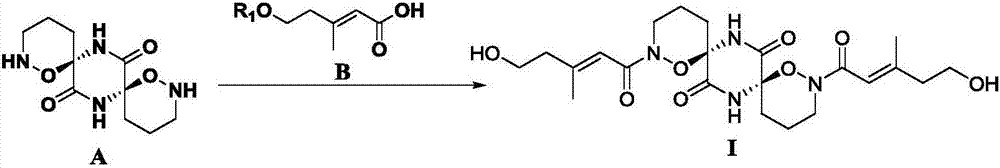

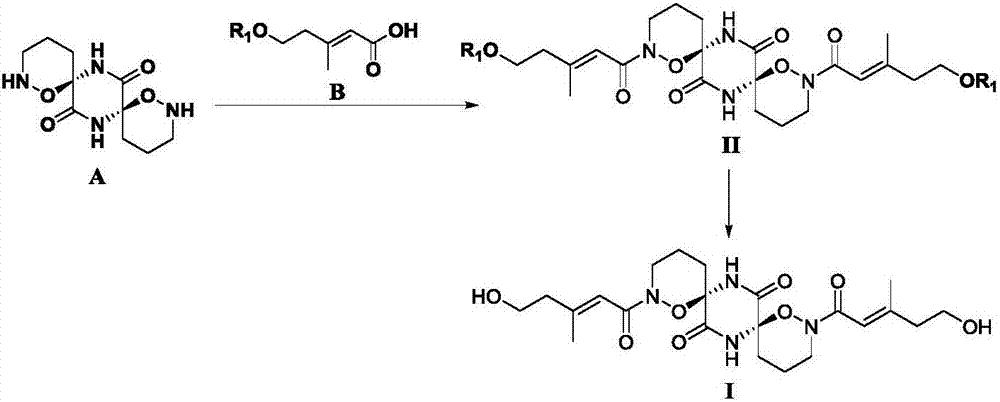

Method for synthesizing natural product (+/-)-Pestaloxazine A from ornithine

The invention relates to a method for synthesizing a natural product (+ / -)-Pestaloxazine A from ornithine. The method comprises the steps of carrying out series reaction such as condensation, oxidation and cyclization on the protected ornithine to obtain a symmetric dioxazine alkane spiropiperazine compound A; and then carrying out condensation reaction on the symmetric dioxazine alkane spiropiperazine compound A and a side chain compound B to prepare the natural product (+ / -)-pestaloxazine A.

Owner:YANGZHOU BLUE BIOMEDICAL TECH CO LTD

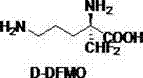

Chemical-enzyme method for preparing D-basic amino acid hydrochloride

InactiveCN102392061AGuaranteed high optical activitySimpler than ion exchange separationOrganic compound preparationAmino-carboxyl compound preparationPenicillinPhenylacetic acid

The invention provides a chemical-enzyme method for preparing D-basic amino acid hydrochloride. The method comprises the following steps of: derivatizing DL-basic amino acid serving as a raw material to obtain DL-N-diphenyl acetyl basic amino acid by utilizing an acylating agent, hydrolyzing the DL-N-diphenyl acetyl basic amino acid by using immobilized penicillin acylase as a biocatalyst through non-stereo selectivity and enantioselectivity to obtain L-basic amino acid, phenylacetic acid and D-alpha-N-phenylacetyl basic amino acid; and performing acidolysis on the D-alpha-N-phenylacetyl basic amino acid to obtain phenylacetic acid and D-basic amino acid dihydrochloride, and performing treatment of epoxypropane to obtain the D-basic amino acid hydrochloride. The D-lysine hydrochloride and D-ornithine hydrochloride which are prepared by the method have the yield of more than 40 percent, and ee is more than 99 percent. The method has the characteristics of high yield and optical purity, simple process and the like, and is suitable for the large-scale production of the D-basic amino acid hydrochloride.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Flavour additives

ActiveCN104837365AImprove palatabilityAnimal feeding stuffAccessory food factorsTryptophanPhenylalanine

The present invention relates to the use of a first amino acid selected from the group consisting of glycine, alanine, cysteine, histidine, leucine, methionine, phenylalanine, serine, tryptophan and tyrosine or a mixture of two or more thereof; a second amino acid selected from the group consisting of aspartic acid, cystine, glutamic acid, glutamine, isoleucine, lysine, aspartic acid, ornithine, threonine, valine, proline and hydroxyproline or a mixture of two or more thereof and one or more furanones for increasing the palatability of a foodstuff to a companion animal. The invention also relates to a pet foodstuff or supplement comprising a first amino acid selected from the group consisting of glycine, alanine, cysteine, histidine, leucine, methionine, phenylalanine, serine, tryptophan and tyrosine or a mixture of two or more thereof; a second amino acid selected from the group consisting of aspartic acid, cystine, glutamic acid, glutamine, isoleucine, lysine, aspartic acid, ornithine, threonine, valine, proline and hydroxyproline or a mixture of two or more thereof and one or more furanones, and also to a method of increasing the palatability of a foodstuff to a companion animal.

Owner:MARS INC

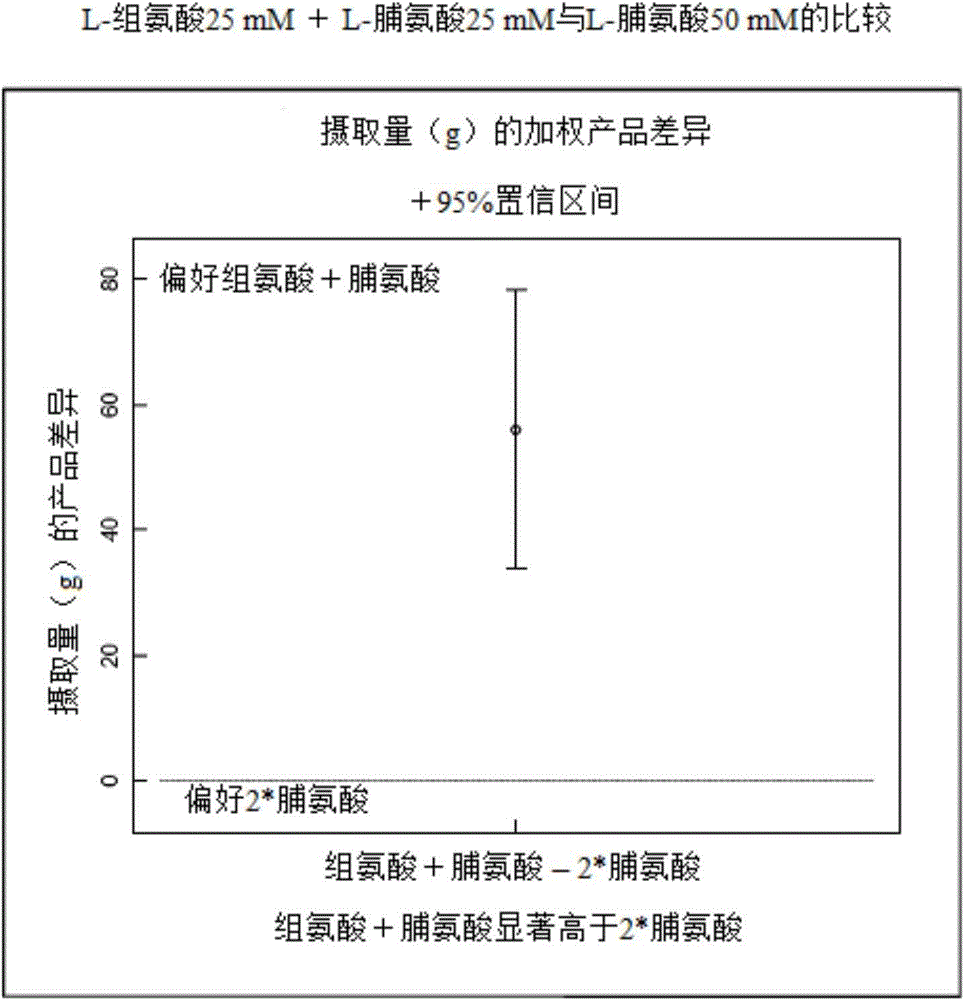

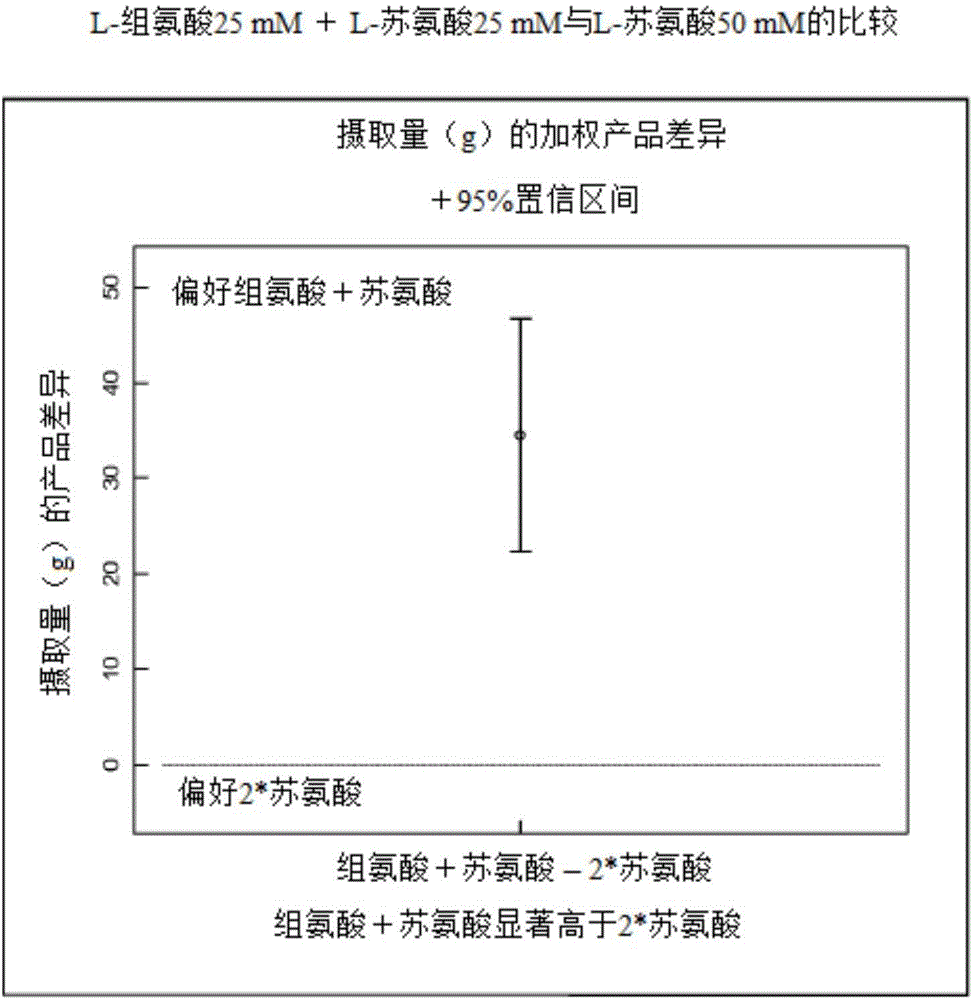

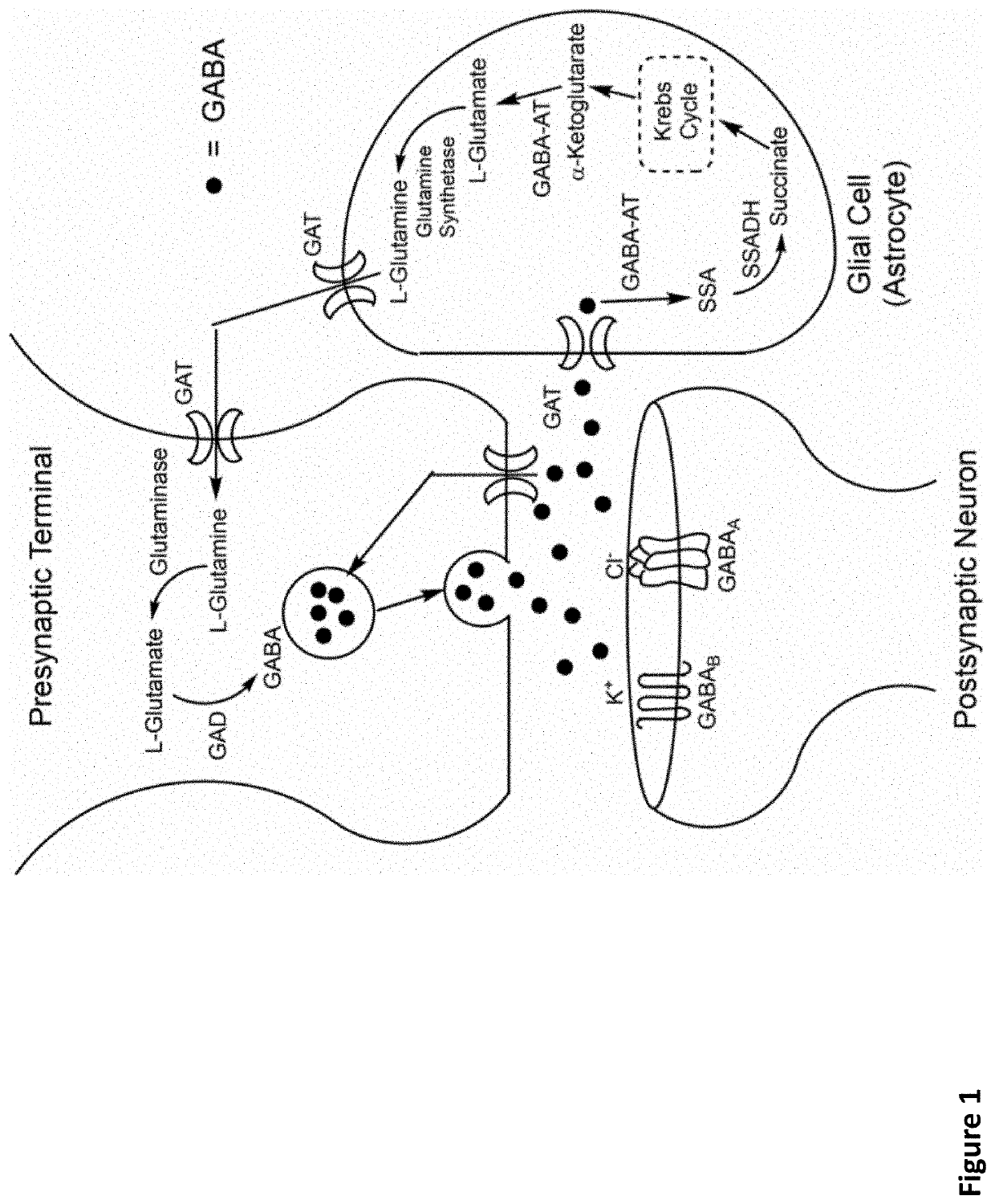

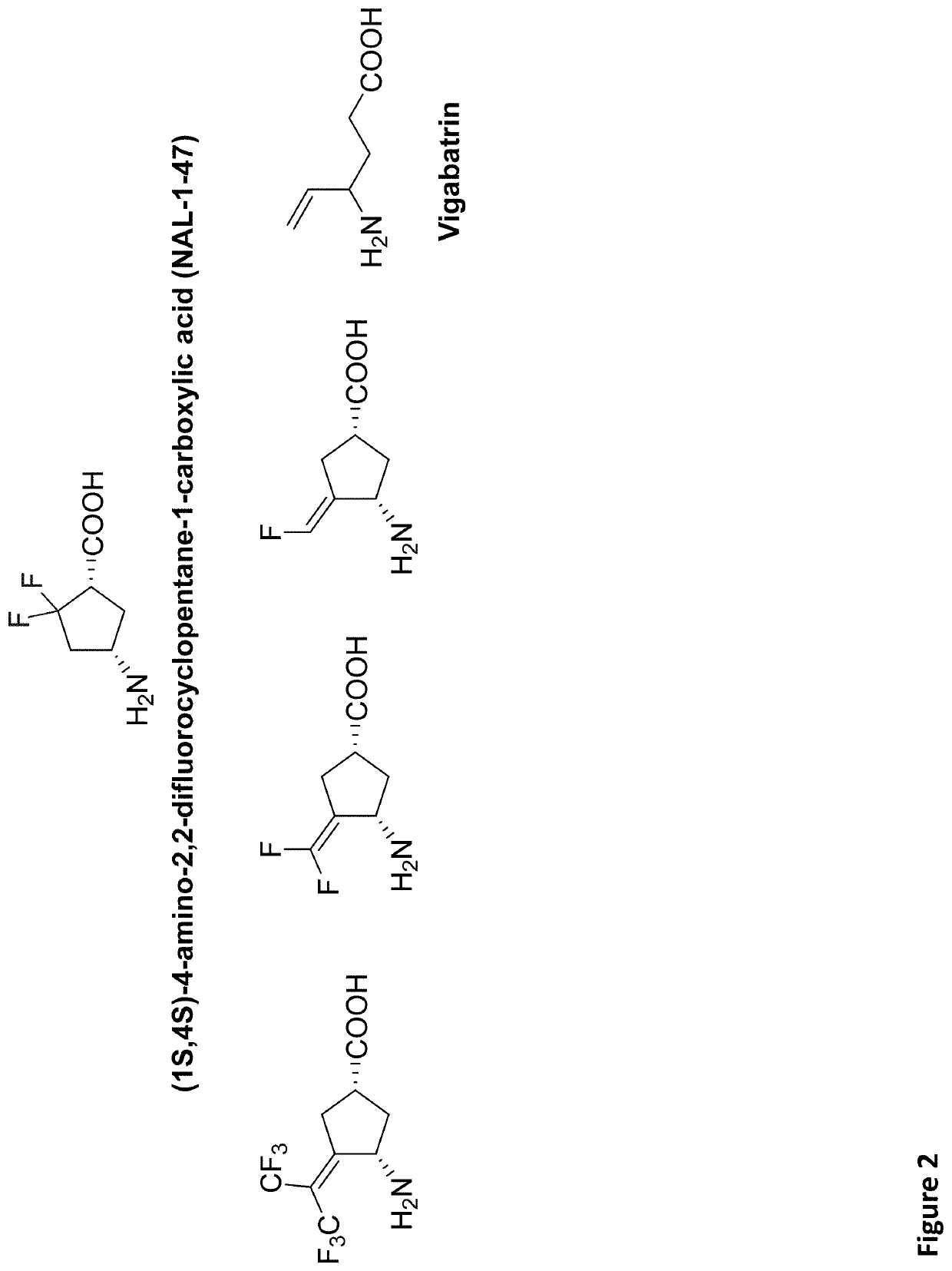

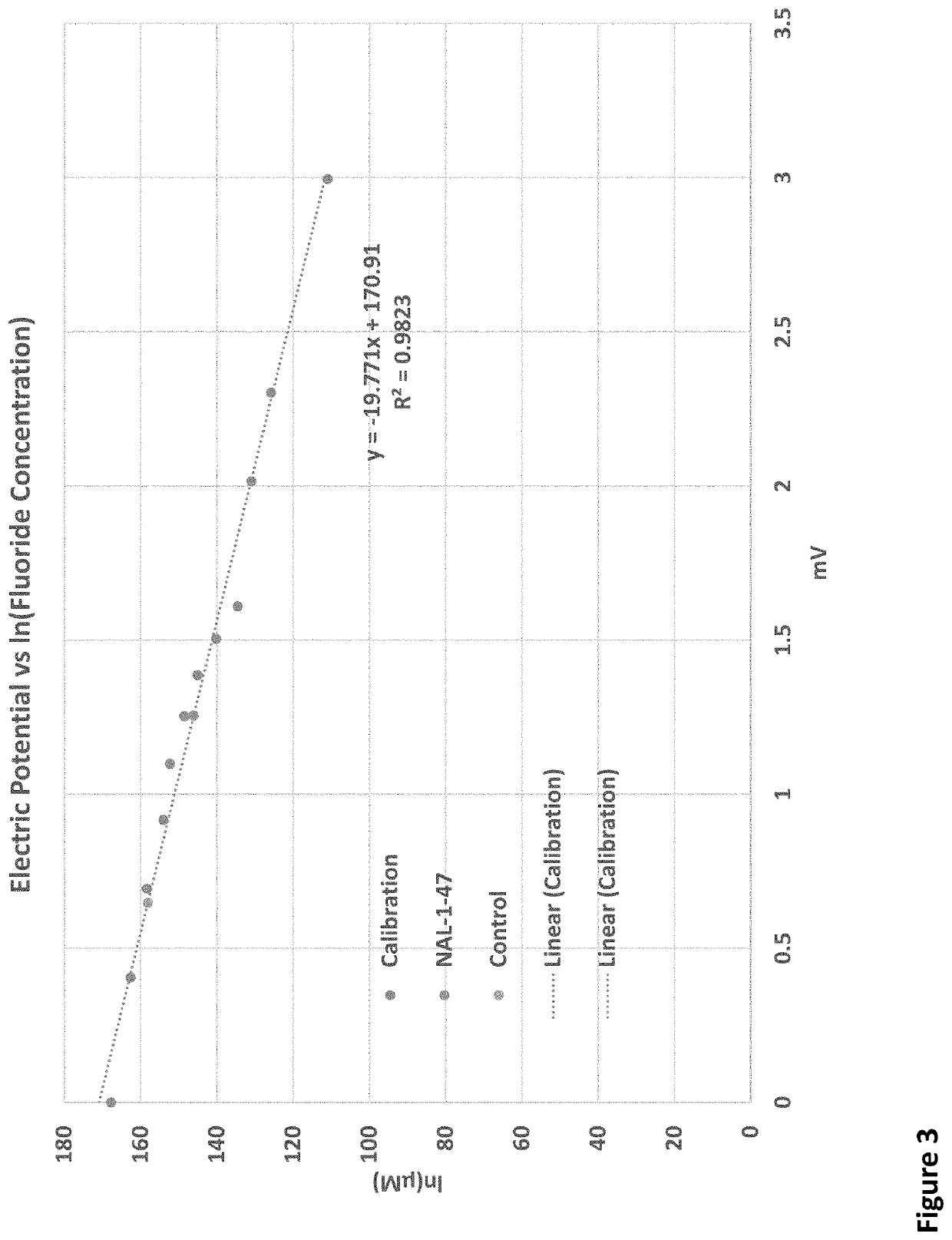

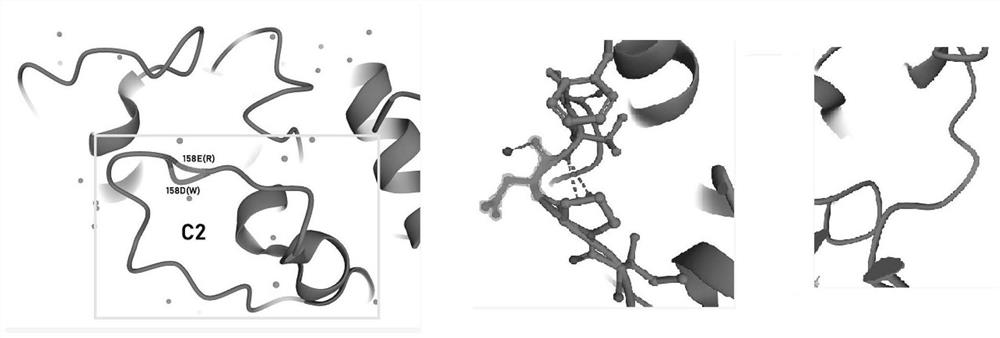

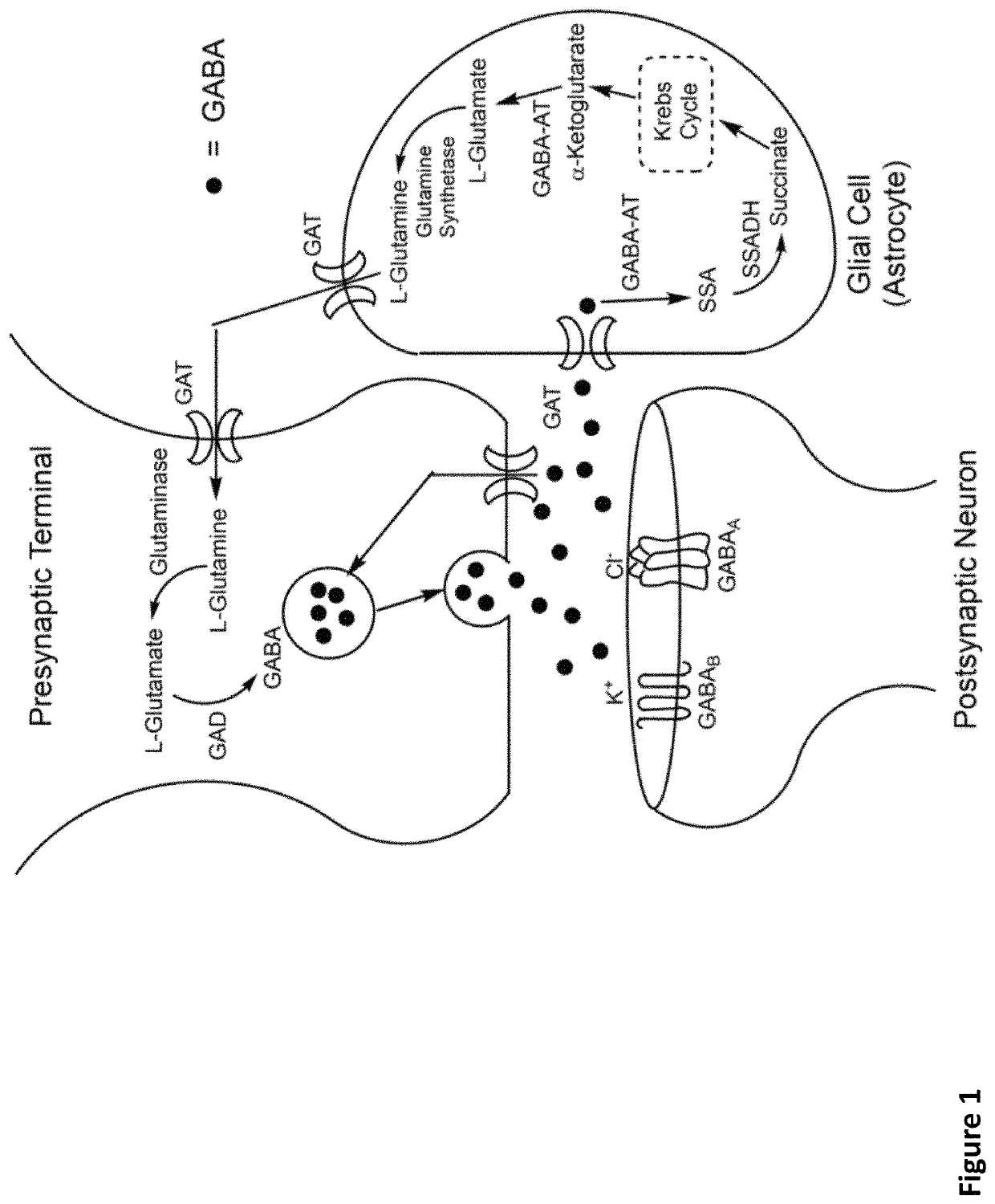

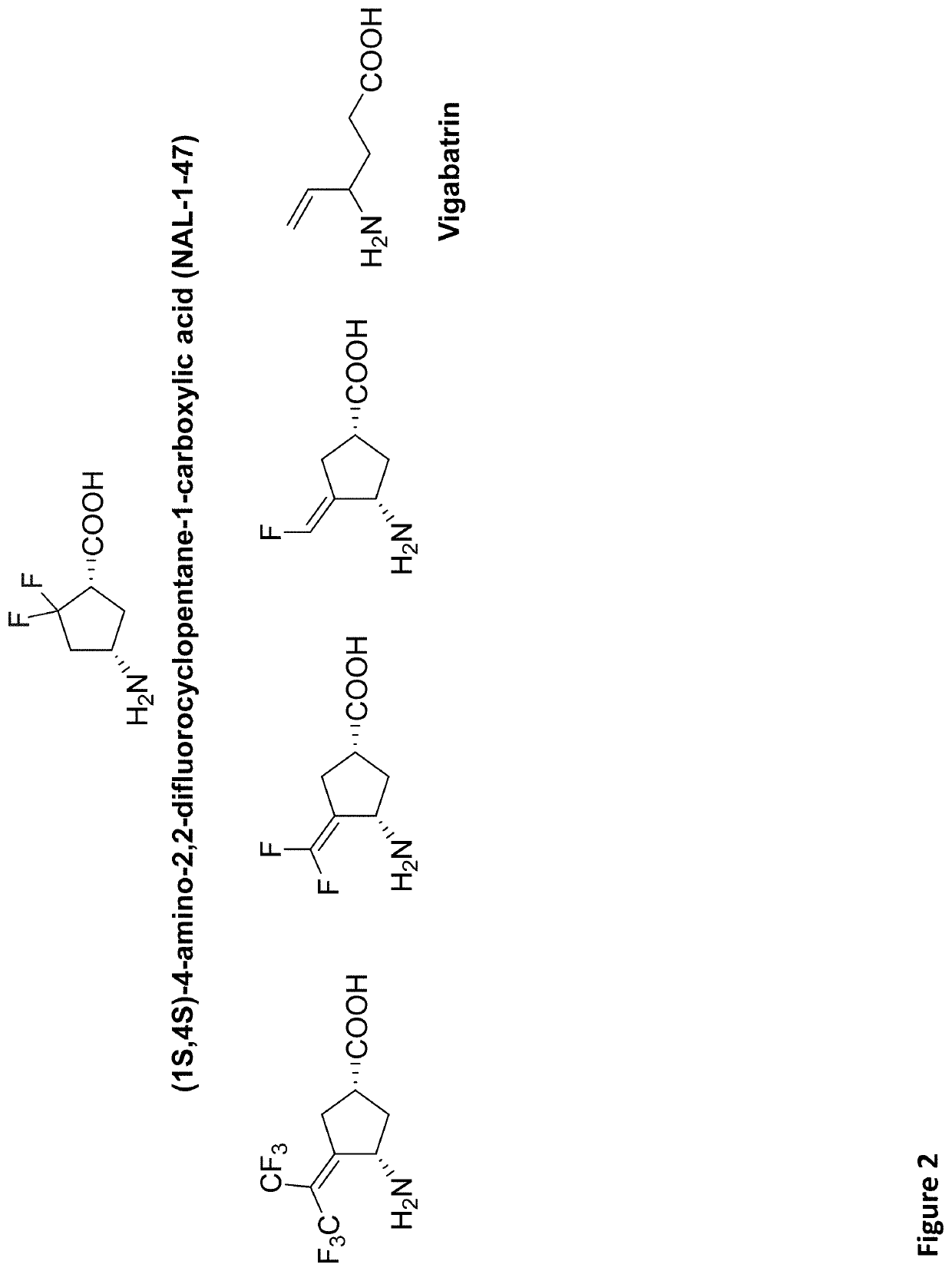

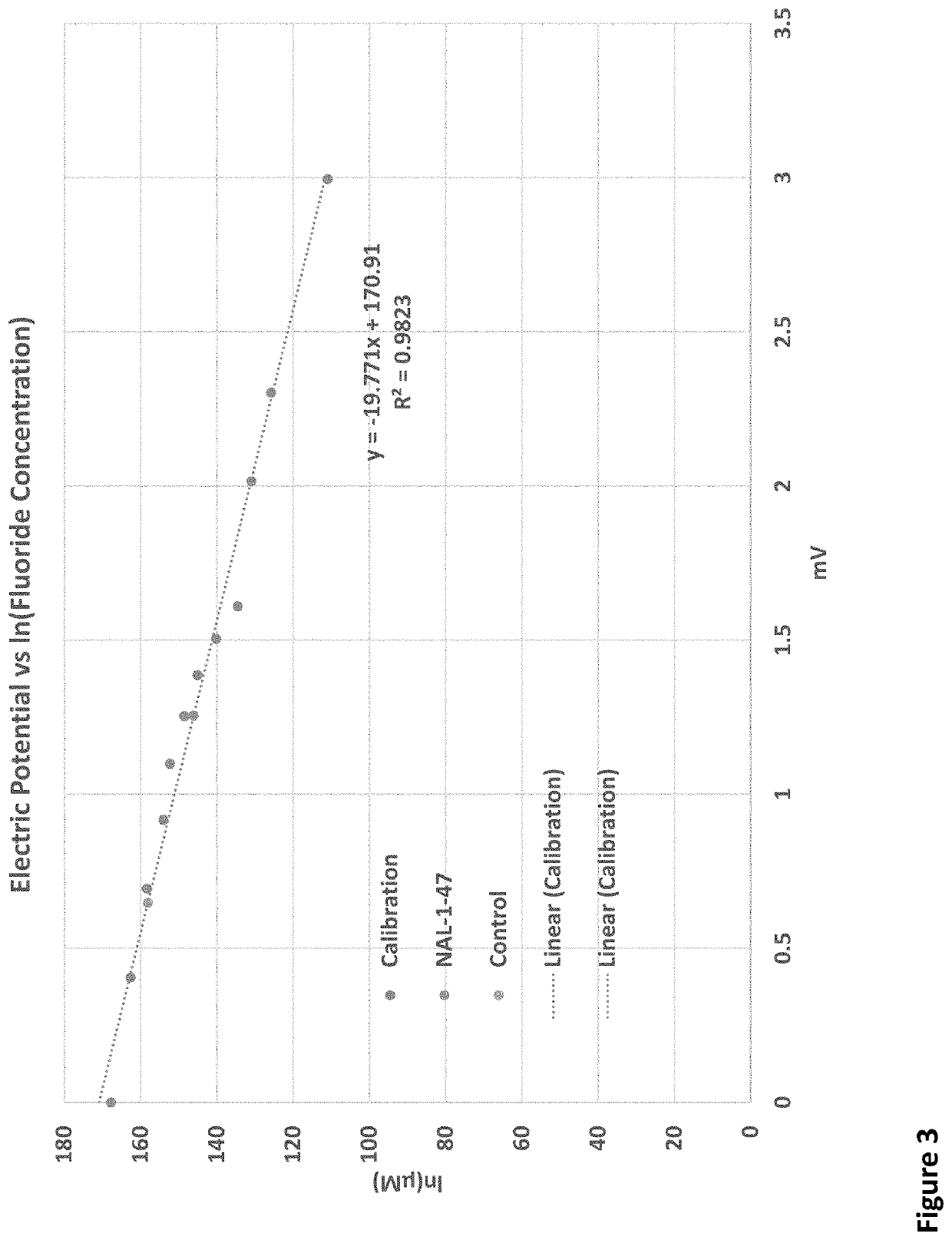

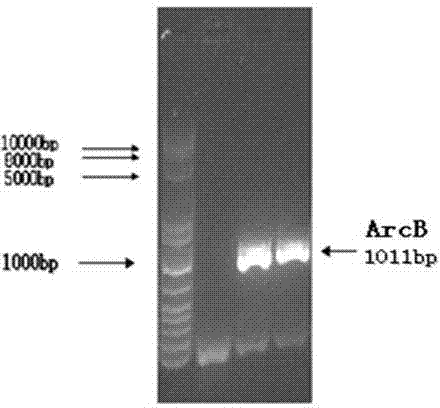

2-difluoro substituted 4-aminocyclopentanecarboxylic acids as inhibitors of gamma-aminobutyric acid aminotransferase and human ornithine aminotransferase

Disclosed are enantiomerically pure cyclopentane-based compounds that are prepared by a multiple-step synthesis process. The disclosed compounds have been designed to inhibit gamma-aminobutyric acid-amino transferase (GABA-AT) activity and ornithine aminotransferase (OAT) activity. Some of the enantiomerically pure compounds inhibit OAT activity more potently than the racemic compound. The disclosed compounds may be used to selectively inhibit OAT activity, for example, to treat hepatocellular carcinoma and / or used to selected inhibit GABA-AT activity, for example, to treat neurological diseases and disorders.

Owner:NORTHWESTERN UNIV

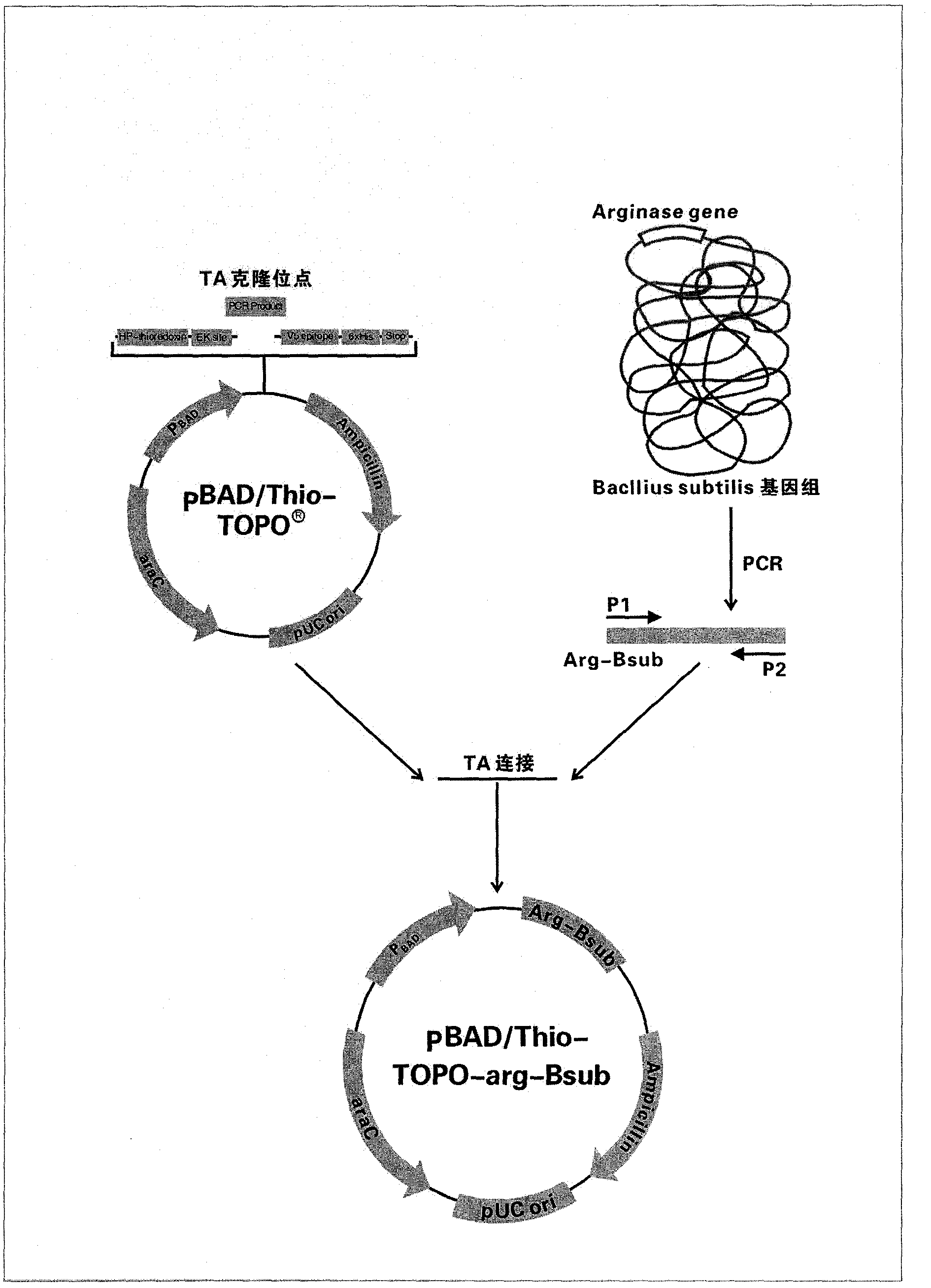

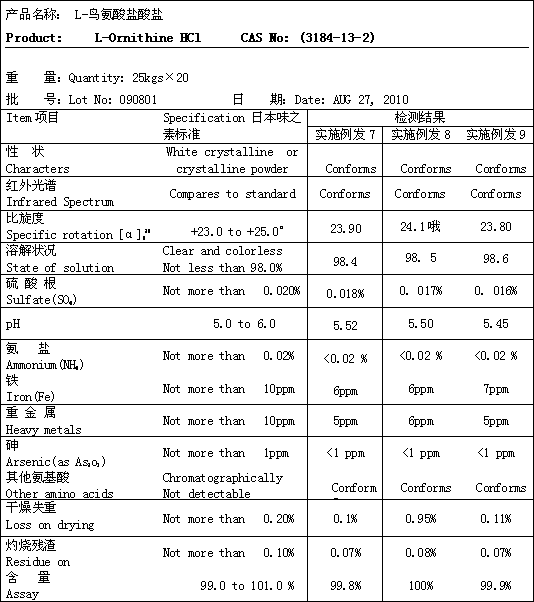

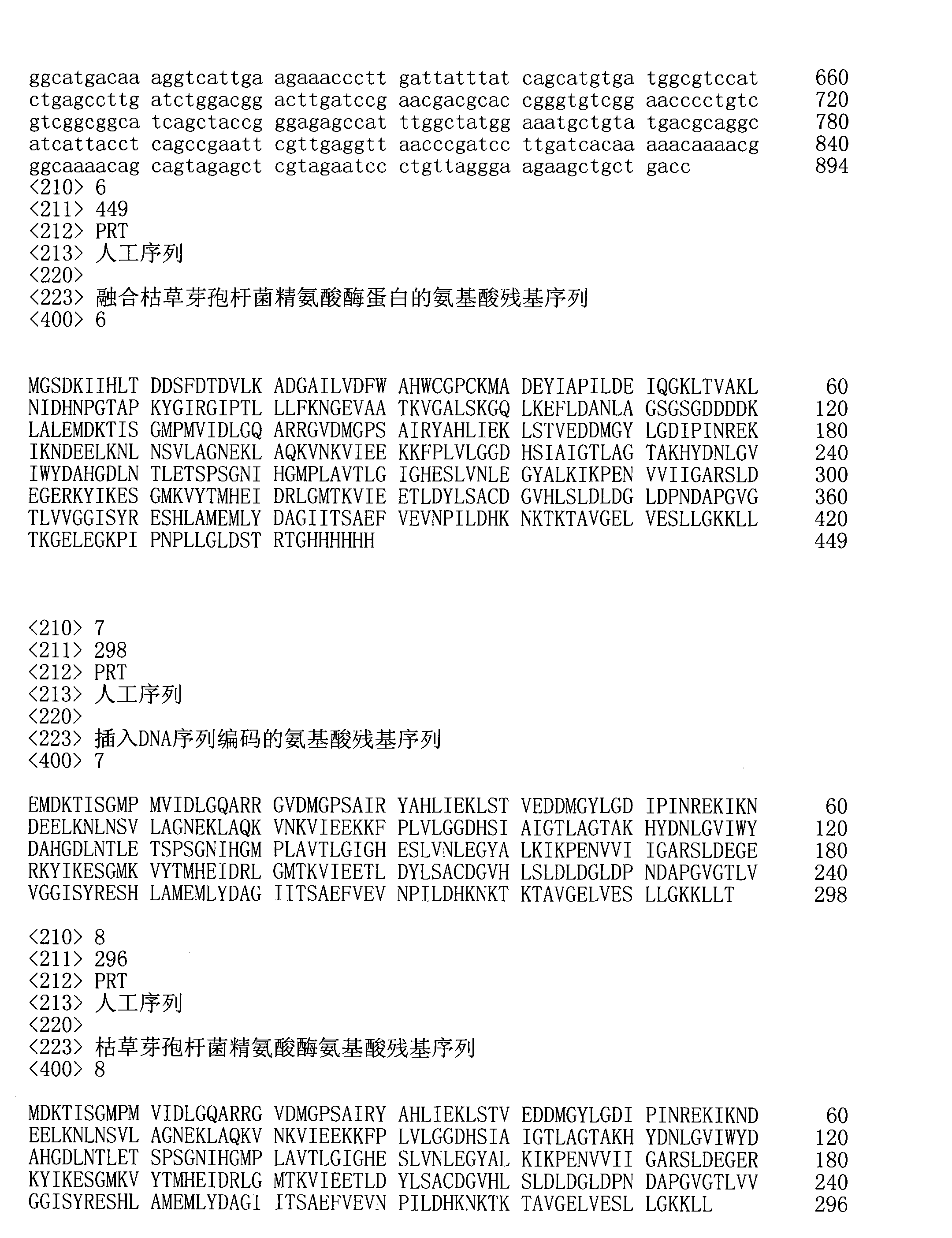

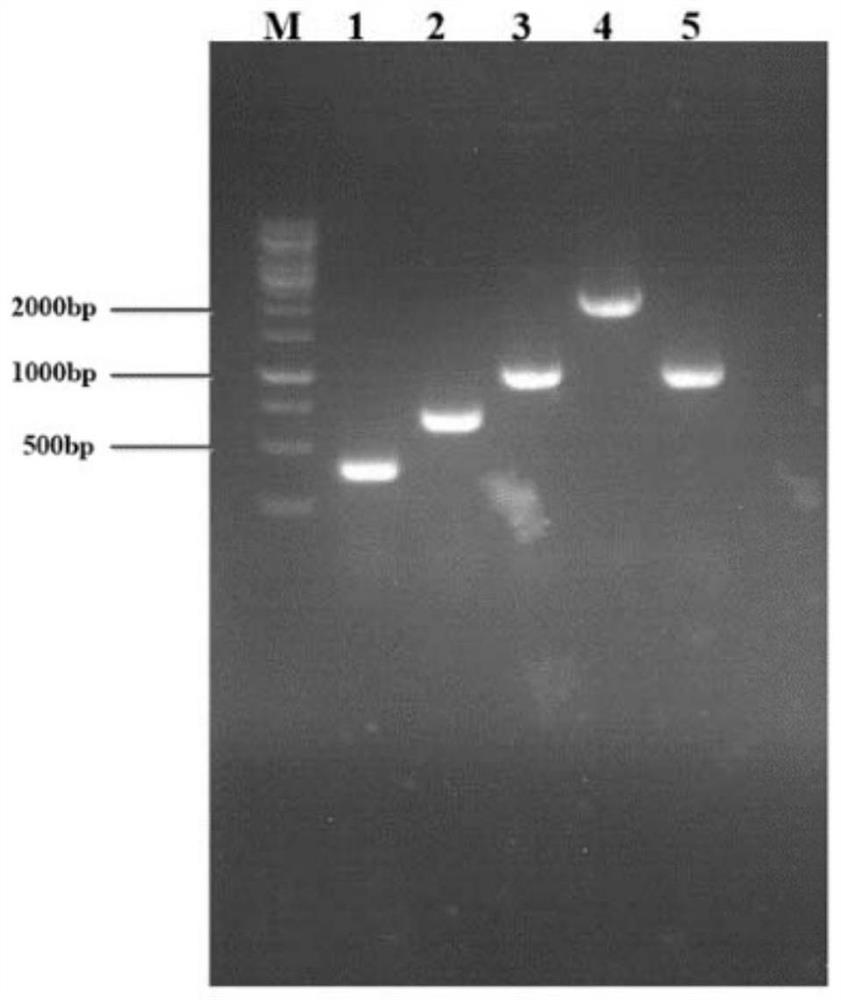

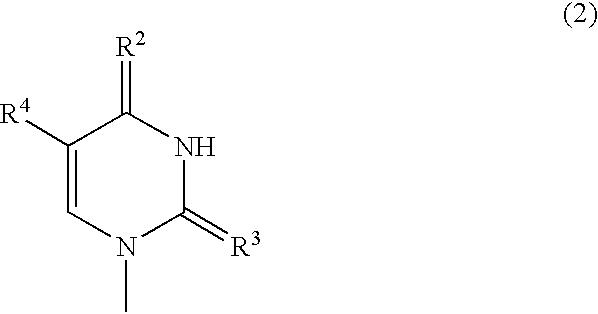

Method for producing L-ornithine hydrochloride by genetic engineering bacteria

ActiveCN102191291BSimple procedureFold preciselyBacteriaMicroorganism based processesThio-Bacillus coli

The invention discloses a method for producing L-ornithine hydrochloride by TOP10 / PBAD / Thio-TOPO-Arg-Bsub colibacillus genetic engineering bacteria. The strain can express and generate excess bacillus subtilis arginase, and efficiently converts L-arginine into L-ornithine.

Owner:WUHAN GRAND HOYO

Genetically engineered strain for producing L-citrulline and application of genetically engineered strain

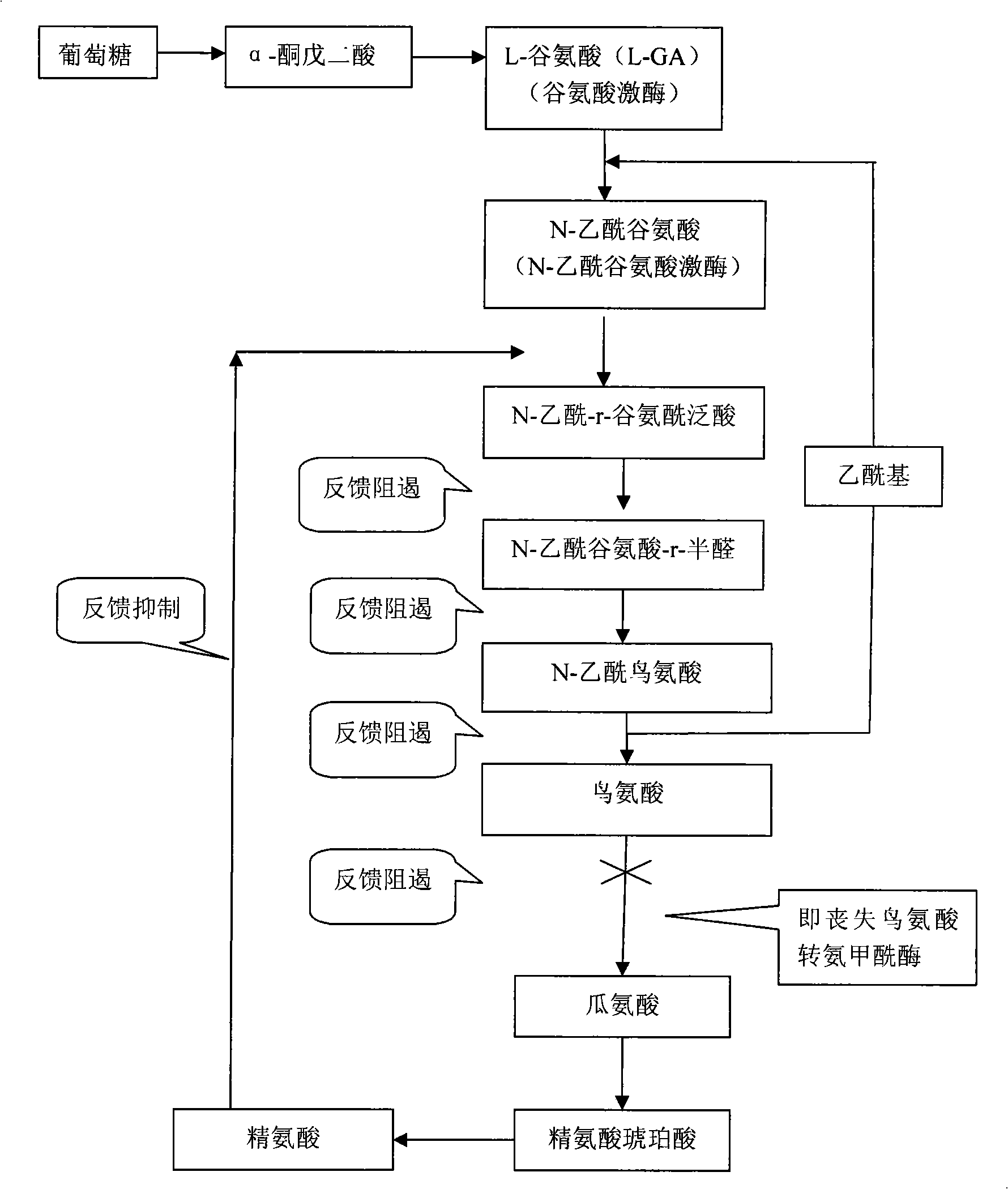

ActiveCN112280728AIncrease production intensityStable fermentationBacteriaHydrolasesEscherichia coliSuccinic acid

The invention provides a genetically engineered strain CIT 4 for efficiently and stably producing Lcitrulline, which takes Escherichia coli as a host, firstly, activity of arginine succinate synthaseis disabled from the host so as to prevent the Lcitrulline from being degraded into arginine succinic acid; a gene argG for encoding escherichia coli arginine succinate synthase being integrated on ahost genome, and expression regulation being carried out by a tryptophan promoter Ptrp; the host is also enabled to delete activity of the acetylornithine deacetylase; a gene argJ of corynebacterium glutamicum coded glutamate acetyltransferase is integrated on a host genome so that the metabolic flow in the process of synthesizing acetylglutamic acid from glutamic acid is enhanced; and genes PyrAAand PyrAB of two subunits of the carbamyl phosphate synthase encoded by the bacillus subtilis mutant strain A260 are also integrated on a host genome so that the feedback inhibition of arginine on the carbamyl phosphate synthase is relieved, and the supply of a precursor substance carbamyl phosphate is improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

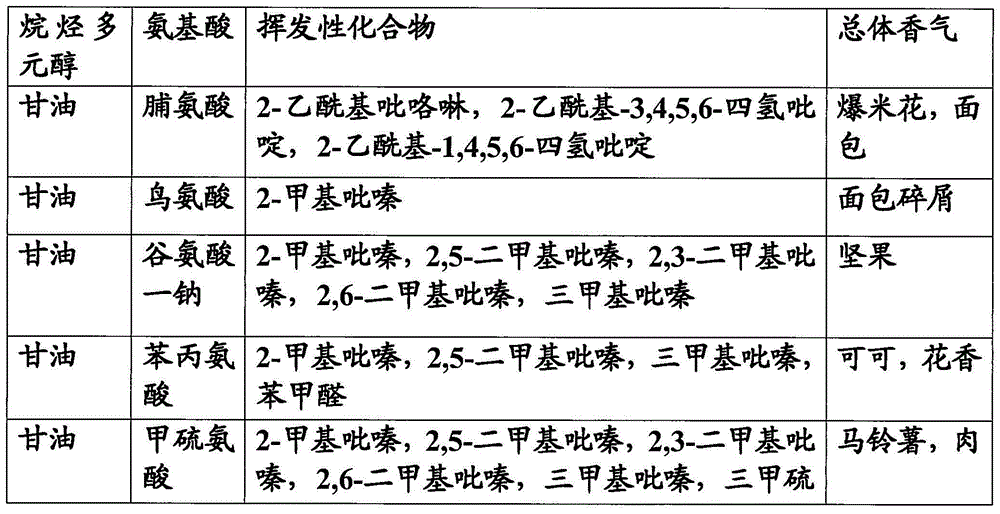

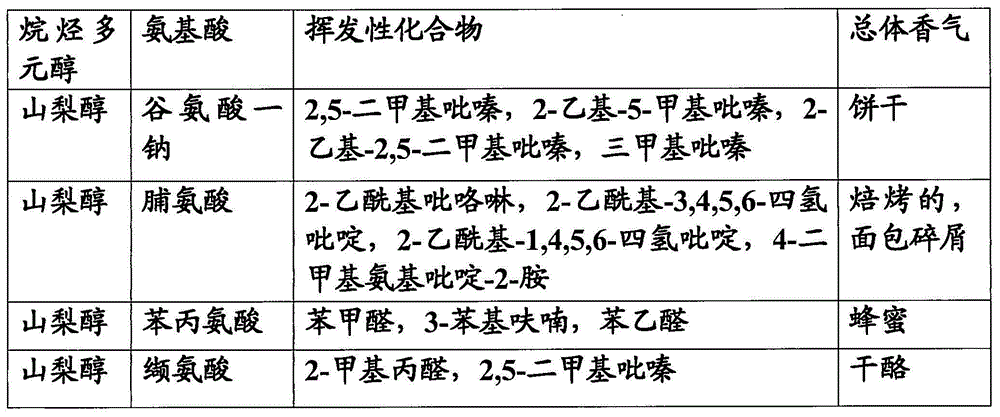

Novel flavour compositions with improved flavour and/or flavour shelf-life

The present invention relates to a novel flavour composition for modulating the flavour of a nutritional product, comprising a mixture of a single amino acid and wet alkane polyol, wherein the single amino acid is selected from the group consisting of ornithine, lysine, glycine, alanine, monosodium glutamate, histidine, threonine, phenylalanine, tyrosine, serine, methionine, arginine, glutamic acid and cysteine. The invention also concerning the use of such a flavour composition for modulating the flavor and / or flavour shelf-life of a nutritional product, the process for preparing such a flavour composition and a nutritional product comprising such a flavour composition.

Owner:NESTEC SA

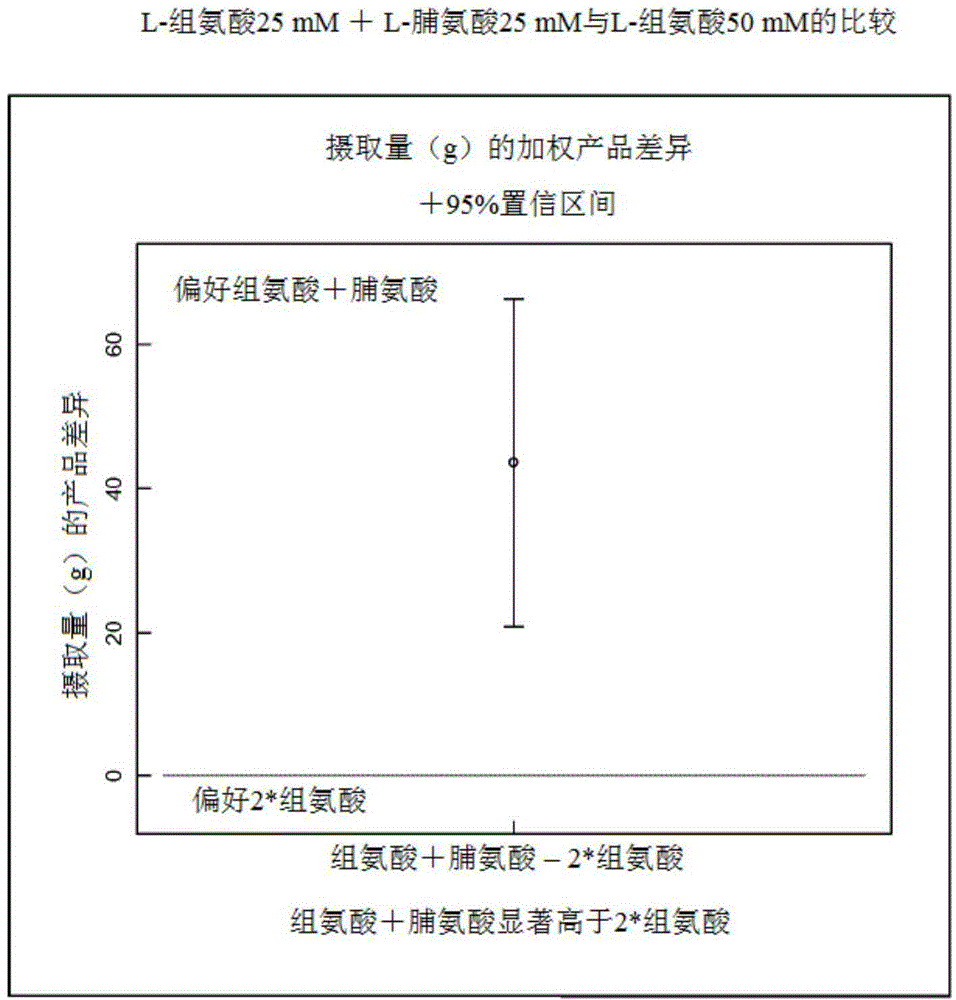

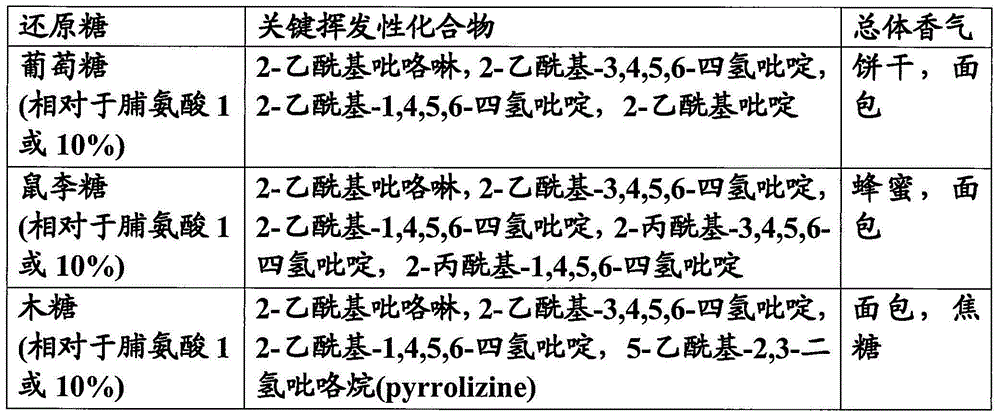

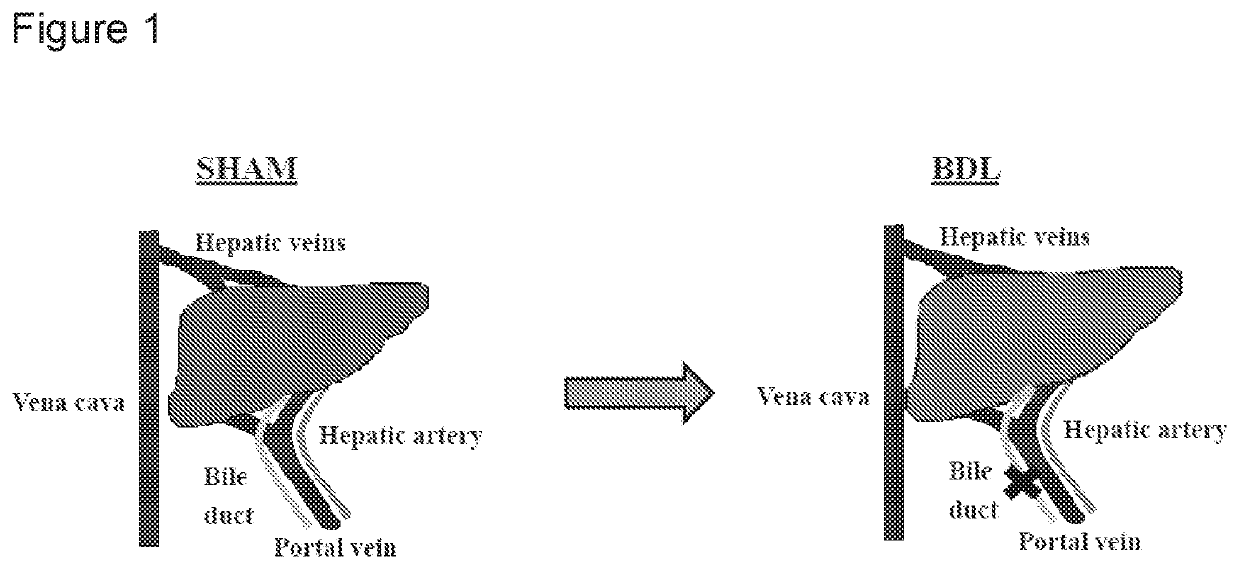

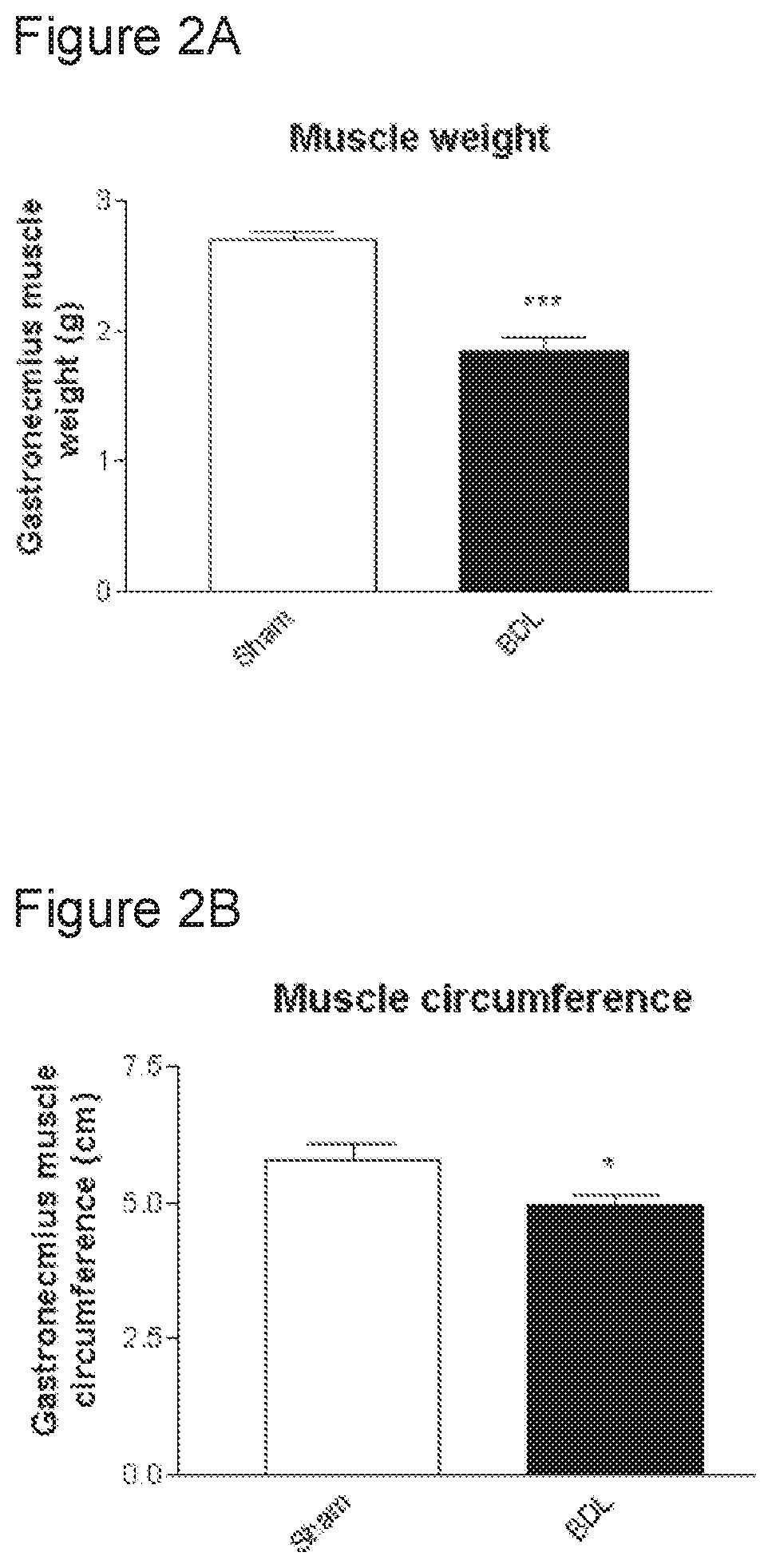

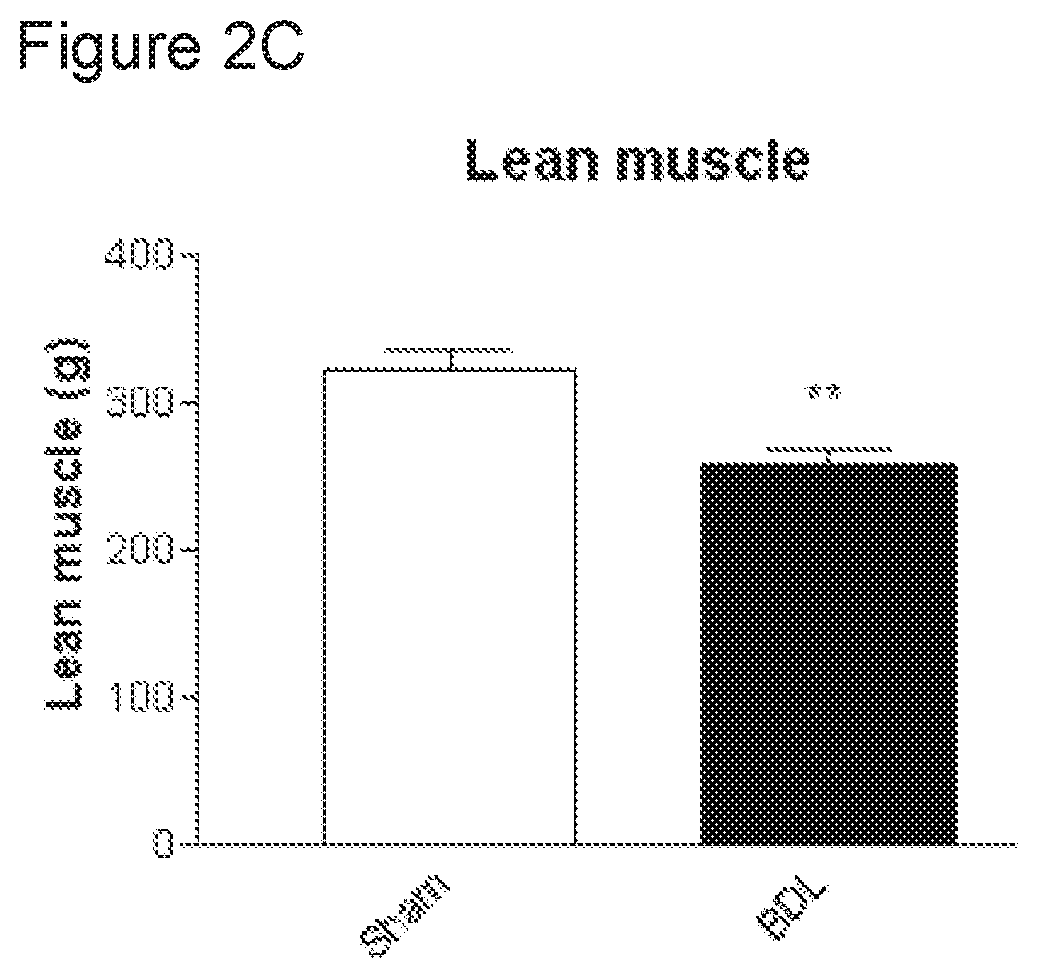

Treatment and prevention of muscle loss using L-ornithine in combination with at least one of phenylacetate and phenylbutyrate

ActiveUS10835506B2Avoid adjustmentReducing blood ammoniaOrganic active ingredientsMicrobiological testing/measurementMuscle lossAcetic acid

Owner:OCERA THERAPEUTICS INC

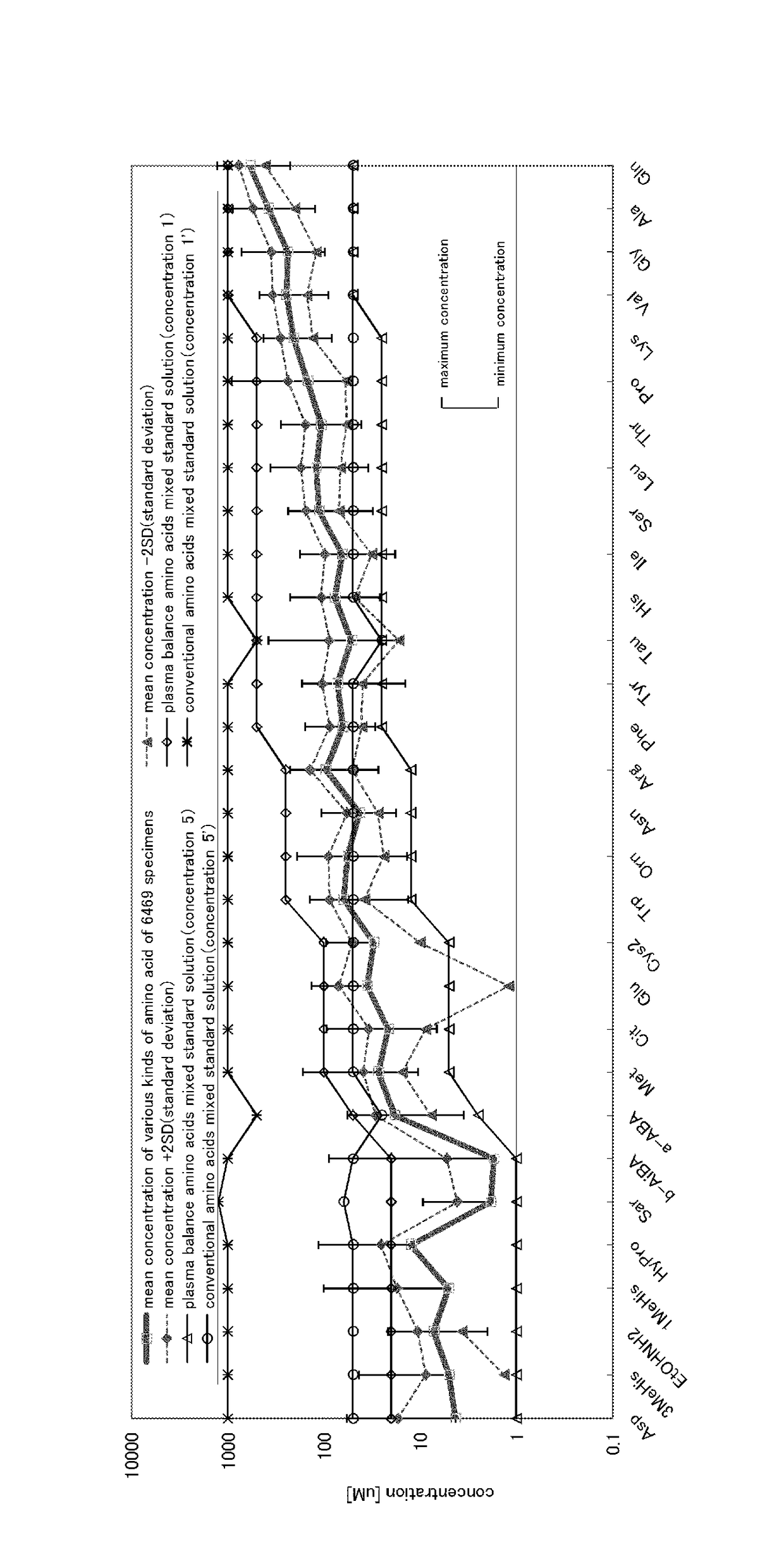

Standard solution for use in analysis of amino acid in plasma

ActiveUS9638706B2Reduce mistakesAccurate measurementComponent separationBiological testingCitrullineThreonine

An external standard solution for use in the analysis of amino acid in plasma, containing,(1) at least one amino acid selected from the following components A, at a concentration of 0.0007 M to 0.49 M, and (2) (i) at least one amino acid selected from the following components B, at a concentration of 0.2 to 0.9 times of the lowest-concentration amino acid among the amino acids selected from components A, (ii) at least one amino acid selected from the following components C, at a concentration of 0.1 to 0.4 times of the lowest-concentration amino acid among amino acids selected from the components A, or (iii) at least one amino acid selected from the following components D, at a concentration of 0.05 to 0.2 times of the lowest-concentration amino acid among amino acids selected from the components A;[Components A] valine, glycine, alanine and glutamine[Components B] serine, proline, threonine, taurine, leucine, isoleucine, lysine, histidine, phenylalanine and tyrosine[Components C] asparagine, ornithine, arginine and tryptophan[Components D] glutamic acid, methionine, citrulline and cystine.

Owner:FUJIFILM WAKO PURE CHEM CORP +1

Method for producing L-ornithine by immobilized enzyme method

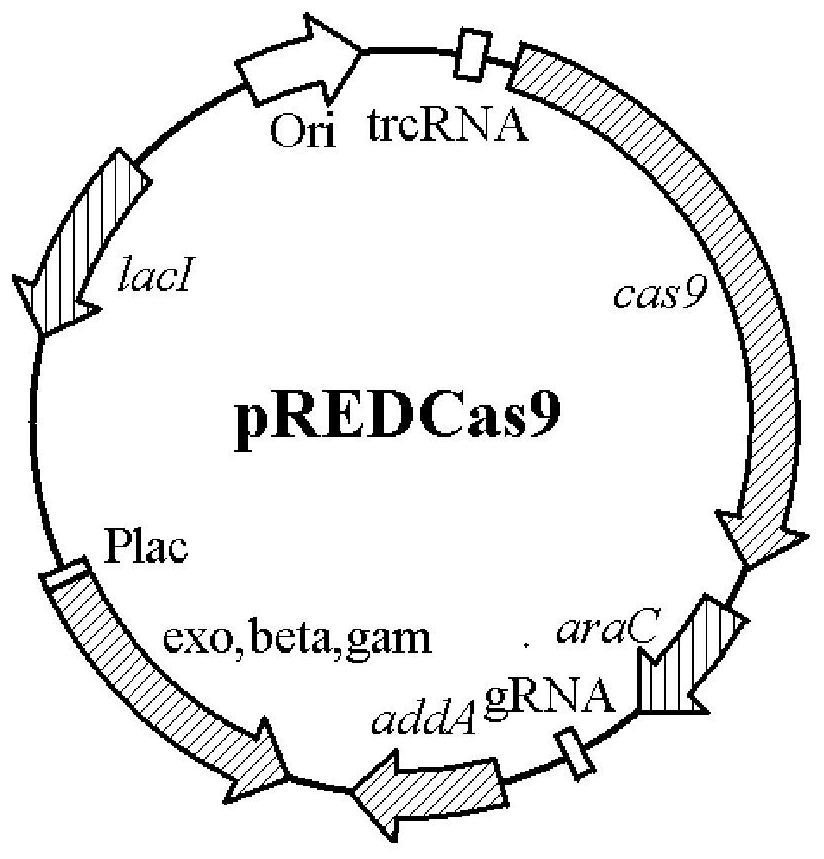

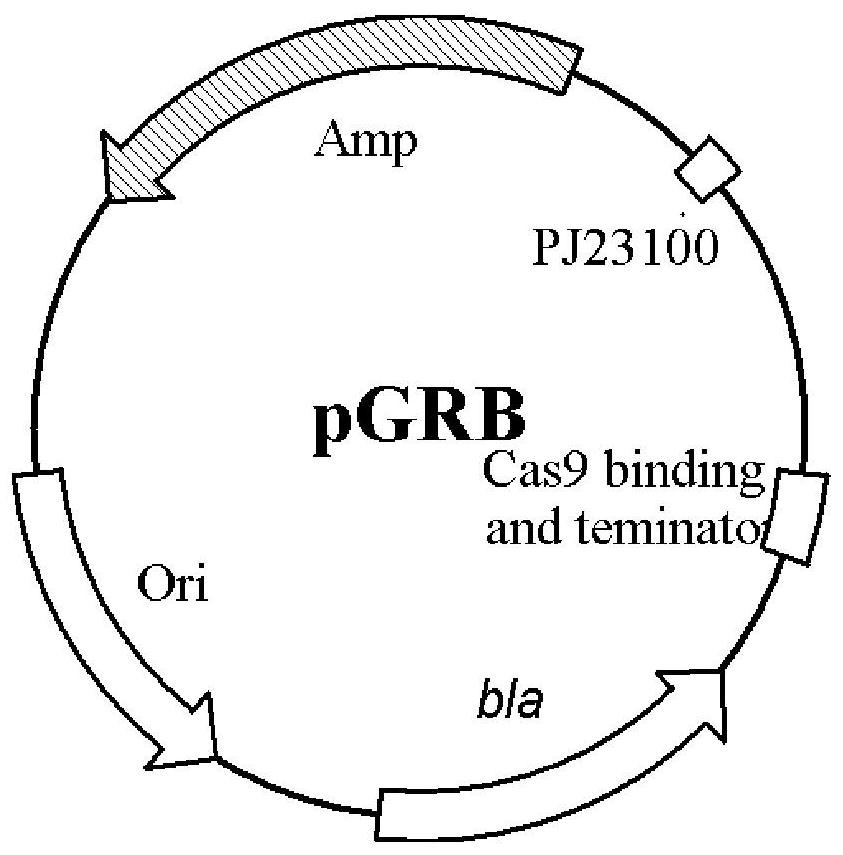

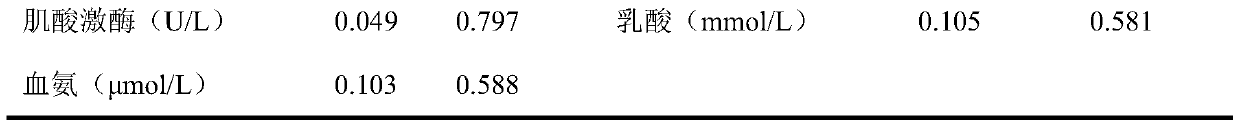

PendingCN114196712AHigh expressionGrow fastBacteriaHydrolasesOrnithine-Oxo-Acid TransaminaseArginase

The invention discloses a method for producing L-ornithine by an immobilized enzyme method, which comprises the following steps: (1) inoculating a seed solution of a human recombinant arginase I producing strain into a fermentation culture medium for fermentation culture, cooling, adding IPTG (isopropyl-beta-d-thiogalactoside) into the system, and performing induced culture for 20-28 hours; (2) carrying out bacterium breaking treatment on the culture solution subjected to induced culture, passing through a ceramic membrane, and collecting filtrate; hanging the filtrate on a column; and (3) enabling a substrate solution containing L-arginine to flow through the nickel column with the hung column for biotransformation, and collecting an effluent transformation solution, so as to produce L-ornithine. According to the invention, a novel human recombinant arginase I producing strain is firstly constructed, and a fermentation process is optimized, so that the yield and enzyme activity of the human recombinant arginase I are improved; then carrying out immobilization treatment on the human recombinant arginase I produced by fermentation by adopting a nickel column hanging column; and then a substrate solution is fed for conversion treatment, so that the L-ornithine is produced by the immobilized enzyme method, and the conversion rate is increased.

Owner:XINTAI JIAHE BIOTECH CO LTD

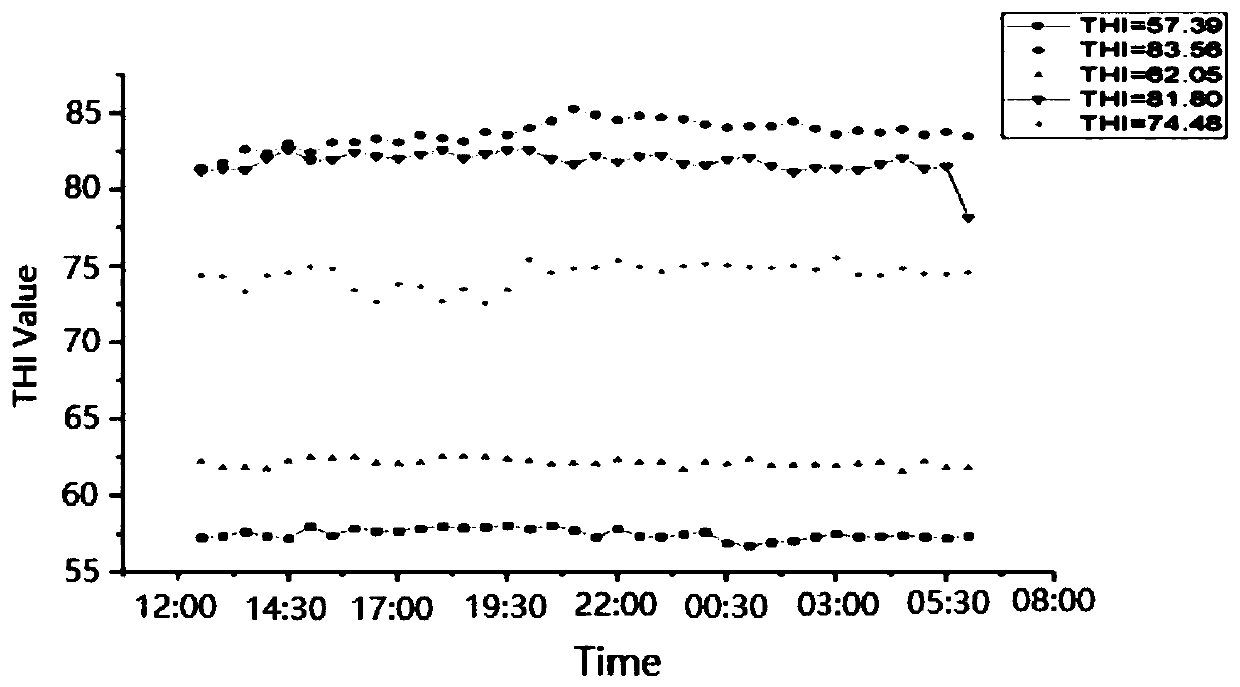

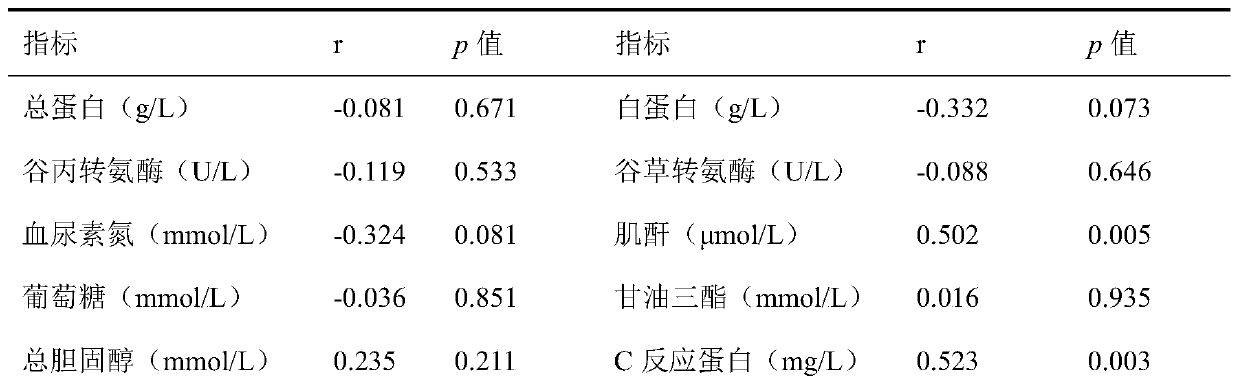

Method for evaluating temperature and humidity state of environment where nursery pig individuals grow

ActiveCN111273044AMicrobiological testing/measurementBiological testingBiotechnologyUrea nitrogen/Creatinine

The invention discloses a method for evaluating the temperature and humidity state of the environment where nursery pig individuals grow. According to the method, biochemical indexes and metabolite concentration in nursery pig blood are quantitatively determined, and the indexes are used for evaluating the temperature and humidity state of the environment where nursery pigs grow. Biochemical indexes and metabolite indexes in blood are as follows: biochemical indexes and metabolite indexes in blood; albumin and glutamic oxalacetic transaminase are added; glutamic-pyruvic transaminase, blood urea nitrogen, creatinine, glucose, triglyceride, total cholesterol, lactic acid, creatine kinase, immunoglobulin M, 3-methyl-L-histidine, ortho-phosphoethanolamine, L-carnosine, L-arginine, ethanolamine, L-glycine, L-aspartic acid, L-sarcosine, beta-alanine, L-ornithine, L-cystine, L-tyrosine, hydroxyproline and alpha-serine.

Owner:INST OF SUBTROPICAL AGRI CHINESE ACAD OF SCI

Inhibition of ornithine aminotransferase for the treatment of proliferative disorders

The invention relates to inhibition of ornithine aminotransferase (OAT) for suppression of tumor cells proliferation. More particularly, the invention relates to methods of treatment of proliferative disorders by the selective inhibition of OAT, and further provides the use of OAT inhibitors, specifically, 5-amino-1,3-hexadienyl-carboxylic acid (Gabaculine), and Gabaculine analogue 8, for compositions and methods for the treatment of proliferative disorders such as hepatocellular carcinoma. The invention further provides methods and kits for the diagnosis of a pathologic proliferative disorder in a mammalian subject, based on determining the level of OAT expressed in a biological sample obtained from a subject.

Owner:HADASIT MEDICAL RES SERVICES & DEVMENT +1

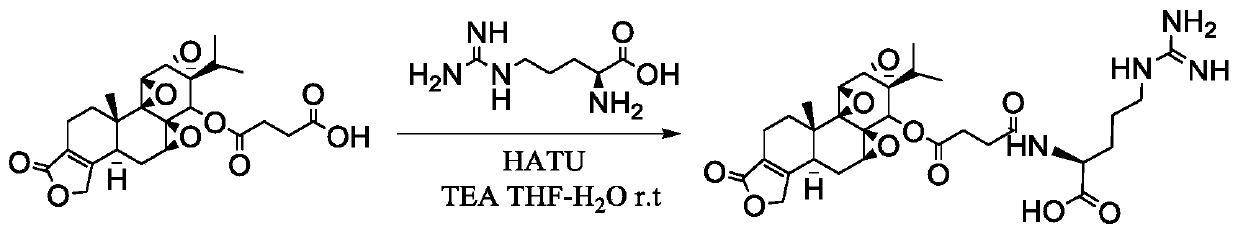

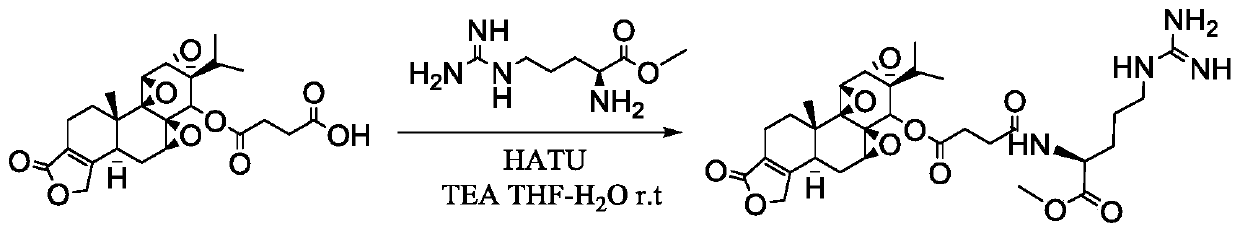

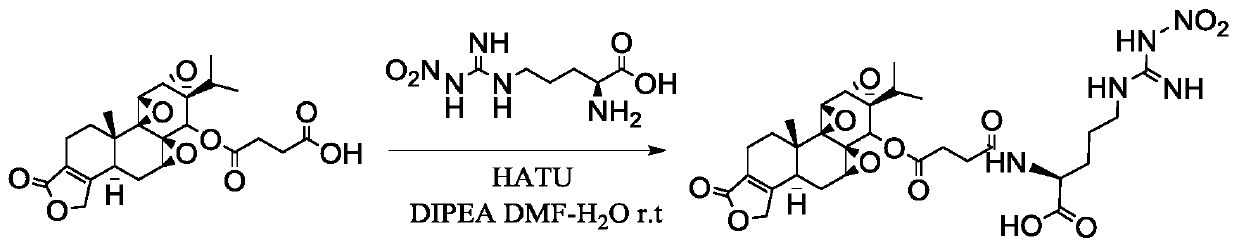

Triptolide targeting prodrug and its preparation method and application

ActiveCN109021061BEfficient developmentEfficient use ofOrganic active ingredientsAntipyreticCitrullineThio-

The invention relates to the technical field of medicines, in particular to a targeting inducible nitric oxide synthase (iNOS) triptolide prodrug, and a preparation method and application thereof. R1of the triptolide targeting prodrug is L-arginine, L-arginine methyl ester, L-Nomega-NO-arginine, L-N omega-NO-arginine methyl ester, L-proline, L-citrulline, L-thiocitrulline or L-ornithine. The highexpression characteristic of the inducible nitric oxide synthase (iNOS) at an inflammatory site is utilized, and the triptolide is semi-synthesized by an iNOS specific substrate (group) to prepare the prodrug, the toxicity of the triptolide is reduced and the bioavailability are improved through the targeting property of the prodrug, the anti-inflammatory effect is significantly better than thatof the triptolide, and the triptolide can be effectively developed and utilized.

Owner:郭可点

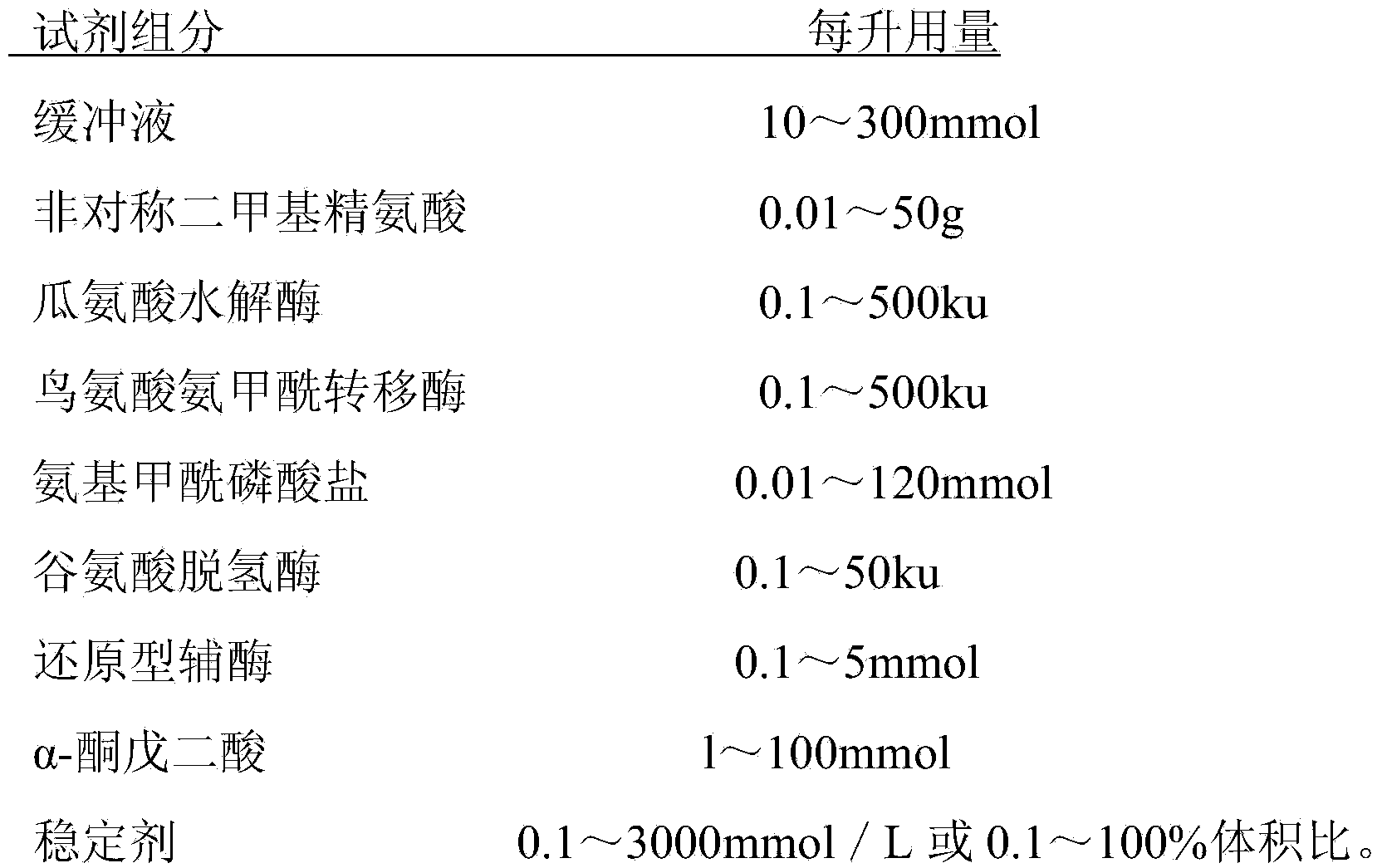

Method for testing dimethyl arginine dimethylamine hydrolytic enzyme and diagnostic reagent thereof

Owner:ZHEJIANG YATAI PHARMA

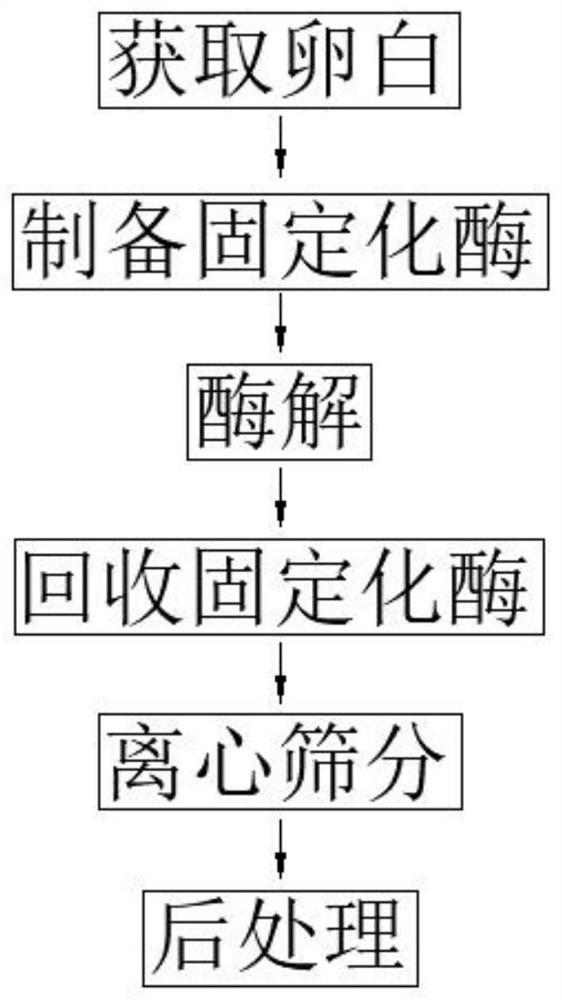

Preparation method of enzymolysis ovalbumin

The invention discloses a preparation method of enzymolysis ovalbumin, and belongs to the technical field of enzymolysis ovalbumin production. The enzymolysis ovalbumin is prepared from the following raw materials in parts by weight: 0.21 to 0.51 part of ornithine, 1.50 to 6.00 parts of lysine, 0.80 to 1.80 parts of histidine, 2.25 to 5.50 parts of arginine, 0.80 to 3.80 parts of threonine, 1.50 to 6.00 parts of serine, 1.41 to 8.24 parts of glutamic acid, 1.00 to 2.58 parts of proline, 0.30 to 2.98 parts of glycine, 1.86 to 5.17 parts of alanine, and the balance of water. The immobilized enzyme can be recycled and can be repeatedly used, so that the investment of the preparation cost is reduced, the immobilized enzyme can be easily and conveniently recycled, time and labor are saved, and the production efficiency of the enzymolysis ovalbumin is guaranteed.

Owner:华亘科技(云南)有限公司

2-difluoro substituted 4-aminocyclopentanecarboxylic acids as inhibitors of gamma-aminobutyric acid aminotransferase and human ornithine aminotransferase

Disclosed are enantiomerically pure cyclopentane-based compounds that are prepared by a multiple-step synthesis process. The disclosed compounds have been designed to inhibit gamma-aminobutyric acid-amino transferase (GABA-AT) activity and ornithine aminotransferase (OAT) activity. Some of the enantiomerically pure compounds inhibit OAT activity more potently than the racemic compound. The disclosed compounds may be used to selectively inhibit OAT activity, for example, to treat hepatocellular carcinoma and / or used to selected inhibit GABA-AT activity, for example, to treat neurological diseases and disorders.

Owner:NORTHWESTERN UNIV

A kind of compound amino acid nutrition package and preparation method thereof

ActiveCN105379967BNutrient consumption is sufficientFull of nutritionAccessory food factorsBiotechnologyArginine

The invention belongs to the technical field of microorganism fermentation and food nutrition, and particularly relates to a compound amino acid nutrition bag and a preparation method thereof. The compound amino acid nutrition bag is prepared from L-arginine, L-threonine, L-ornithine, L-lysine, L-proline, L-glutamic acid, L-valine, L-phenylalanine, L-leucine, organic protein and reducing sugar. The compound amino acid nutrition bag is rich in nutritional ingredient, green, healthy, fragrant and sweet in taste, diverse in type and capable of being widely applied to feed. The preparation method comprises the processes of L-arginine seed enlarge culturing, fermental culturing, micro-filtering for bacterium removal, concentration cream forming or concentration drying, and the preparation method is simple.

Owner:STAR LAKE BIOSCI CO INC ZHAOQING GUANGDONG

Composition for soothing liver-gallbladder, detoxifying and protecting liver and preparation method thereof

The invention discloses a composition for soothing liver-gallbladder, detoxifying and protecting liver and a preparation method thereof. The composition is prepared from the following raw materials in parts by weight: 12-15 parts of liver extract, 20-22 parts of silybum marianum, 9-11 parts of ornithine and 3-5 parts of turmeric. The composition can significantly improve abnormality of indexes of glutamic oxalacetic transaminase, glutamic-pyruvic transaminase, total protein, albumin, globulin, total bilirubin, direct bilirubin, total bile acid and alkaline phosphatase, repair liver injury, significantly enhance the hangover alleviating ability and improve bad symptoms after drinking or after drunkenness, and the composition is easy to industrially produce and popularize and use.

Owner:杨劲松 +1

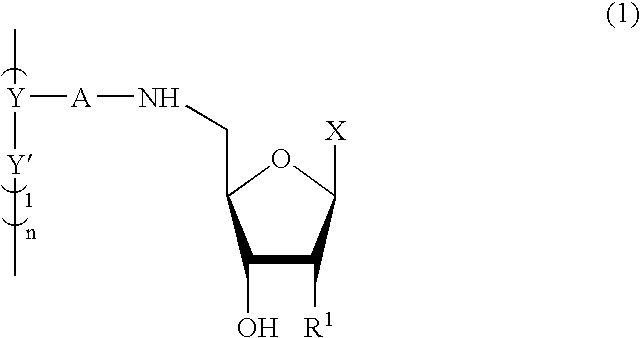

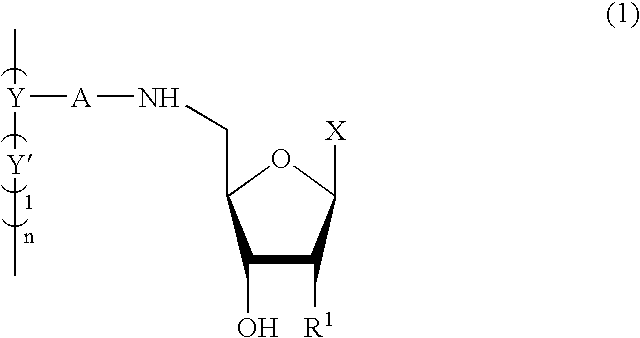

Nucleoside derivatives

InactiveUS20030208050A1High affinitySugar derivativesPeptide/protein ingredientsThreonineGlutamic acid

Novel nucleoside derivatives represented by the following general formula (1): wherein X is(are) the same or different and each represents a pyrimidine or purine base or a derivative thereof, Y-and Y' are the same or different and each represents at least one amino acid or amino acid derivative selected from the group consisting of serine, threonine, ornithine, aspartic acid, glutamic acid, lysine, arginine, cysteine, methionine, delta-hydroxylysine, N-aminoethylglycine, N-aminoethylserine, N-aminoethyllysine, N-aminoethylornithine, N-aminoethylaspartic acid, N-aminoethylglutamic acid, homoglutamic acid, beta-thiocarbonylaspartic acid, gamma-thiocarbonylglutamic acid, and delta-thiocarbonylhomoglutamic acid, R<1 >represents a hydrogen atom or a hydroxyl group, A represents a single bond or a carbonyl or thiocarbonyl group, 1 is an integer of 0 to 5, and n is an integer of 1 to 100.

Owner:JAPAN SCI & TECH CORP

Enzymological detection method

InactiveCN103207173BSensitive detectionSimple and fast operationChemiluminescene/bioluminescenceOrnithine CarbamoyltransferaseCitrulline

The present invention relates to the technical field of inspection and measurement. Disclosed is an enzymology detection method for detecting concentration of citrulline and asymmetric dimethylarginine (ADMA) in a reaction system by using an ATP detection method. The basic principle of the reaction is mainly as follows: ADMA is hydrolyzed by using dimethylarginine dimethylaminohydrolase to obtain citrulline; when ADP and Mg2+ exist, the citrulline is coupling-catalyzed by using ornithine carbamoyltransferase and carbamoyl phosphate kinase to finally obtain ornithine, carbon dioxide, ammonia gas, and ATP, wherein the released ATP can be detected by using a reagent. The present invention has the advantages of flexible and quick reaction, high accuracy, and low cost; ADMA or citrulline with the concentration of 0.1μmol / L at lowest can be detected, and the detection result approaches the concentration of ADMA in the normal serum and is far less than the concentration of citrulline in the normal serum, thereby providing a new applicable method for clinical ADMA detection.

Owner:SHAOXING INST OF TECH COLLEGE OF ENG PEKING UNIV BIOENG CENT

Amino acid composition beneficial to proliferation of lactobacillus acidophilus and application thereof

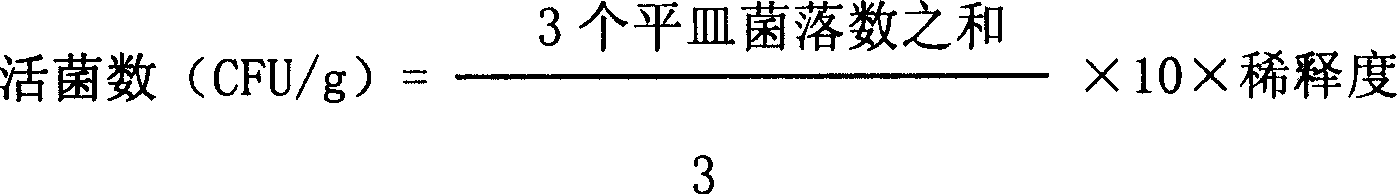

ActiveCN111004747AMeet quantity requirementsBacteriaMicroorganism based processesSuccinic acidLactobacillus acidophilus

The invention discloses an amino acid composition beneficial to proliferation of lactobacillus acidophilus and an application thereof, which belong to the technical field of probiotic fermentation. The amino acid composition includes conventional amino acids and / or other amino acids. Other amino acids are the mixture of one or more of phosphoserine, phosphoethanolamine, ethanolamine, taurine, citrulline, homocitrulline , sarcosine, hydroxyproline, alpha-aminobutyric acid, alpha-aminoadipic acid, beta-alanine, beta-aminoisobutyric acid, ornithine, n-valine, alloisoleucine, n-isoleucine, homocysteine, delta-hydroxylysine, 1-methylhistidine, 3-methylhistidine, gamma-aminobutyric acid, carnosine, goose carnosine, cystathionine and arginine succinic acid. The content of viable bacteria in fermentation liquor is greater than 3.0*10<9> cfu / mL, and the content of viable bacteria in freeze-dried bacterial powder is greater than 3.5*10<11> cfu / g. The demand of the existing market for the numberof lactobacillus acidophilus is satisfied.

Owner:郑州和合生物工程技术有限公司

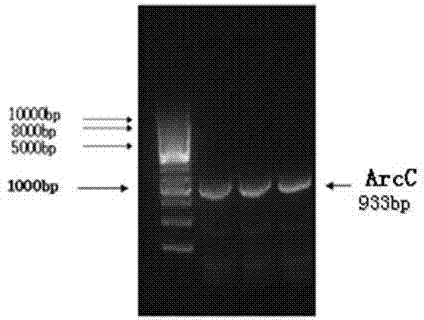

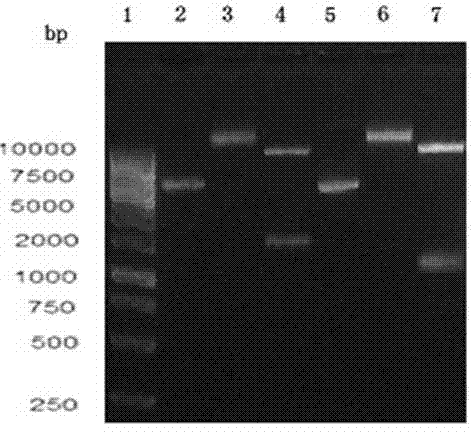

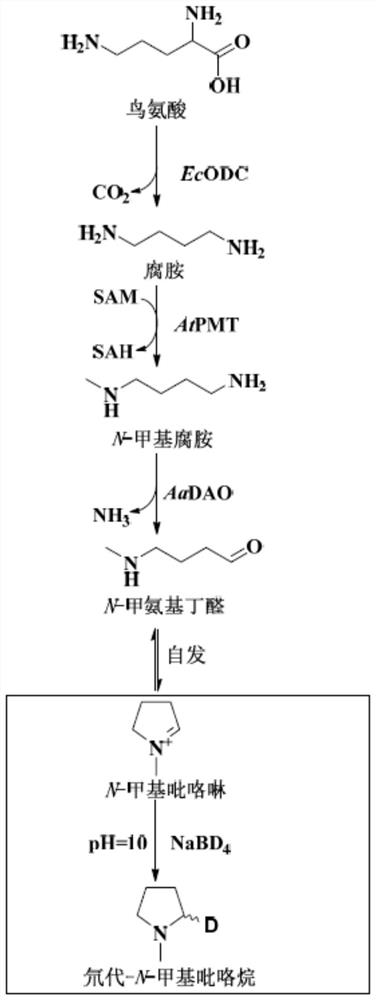

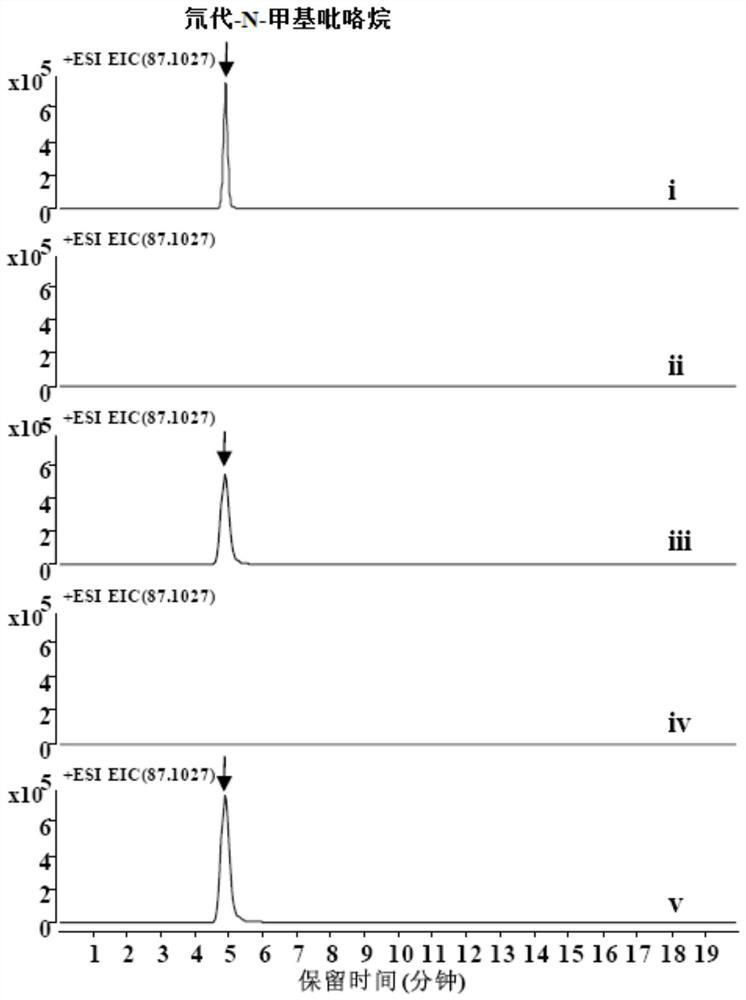

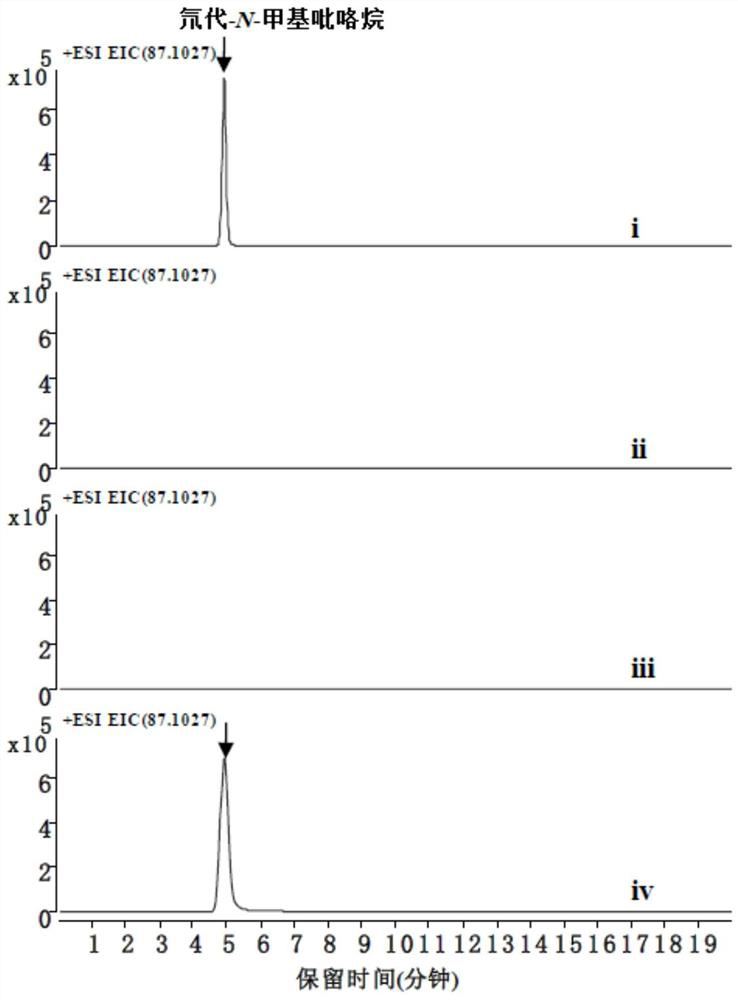

The biosynthesis method of n-methylpyrroline

The invention provides a method for preparing N-methylpyrroline through the combined catalysis of three enzymes, comprising the following steps: using L-ornithine as a substrate, using ornithine decarboxylase EcODC, putrescine-N-methyl It is obtained through joint catalysis of transferase AtPMT and amine oxidase AaDAO3. The above method can also be realized by fermentation of genetically engineered bacteria expressing these three enzymes. The method of the invention is environment-friendly, has warm reaction conditions, and has industrialized development prospects.

Owner:CAS CENT FOR EXCELLENCE IN MOLECULAR PLANT SCI

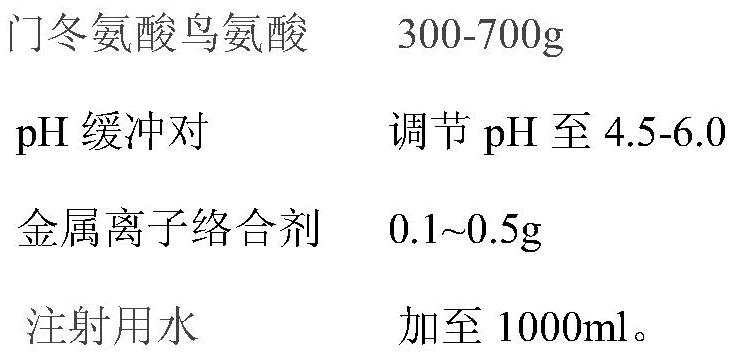

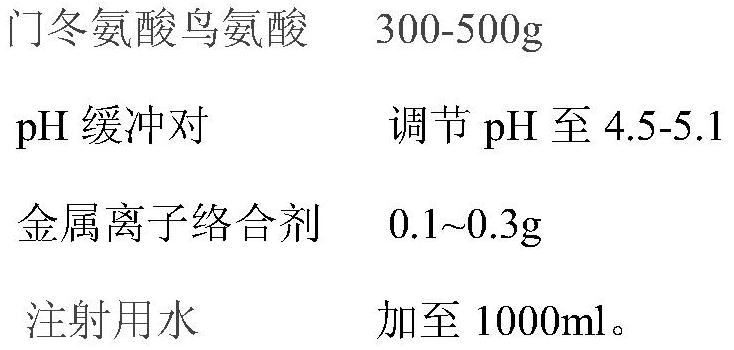

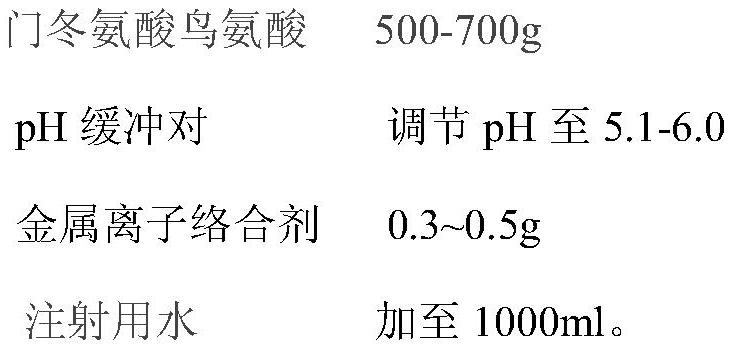

A kind of aspartic acid ornithine injection and preparation method thereof

ActiveCN107441038BAvoid cyclizationAvoid decomposition catalysisOrganic active ingredientsNervous disorderArginineOrnithine-Oxo-Acid Transaminase

The invention relates to the field of pharmaceutical preparations, in particular to an ornithine-aspartate injection and a preparation method thereof. If impurities such as amide, arginine, and dimeric ornithine exceed the standard, the following prescription is adopted: including pre-purified aspartic acid ornithine, metal ion complexing agent, pH buffer pair and water for injection, in which the pH buffer pair In order to maintain the stable pH of the injection, the metal ion complexing agent avoids the decomposition and catalysis of the main drug by the metal ion; the preparation process of the present invention includes: two parts: pre-purification of aspartic acid ornithine and preparation of the medicinal solution, wherein Pre-purification adopts the method of recrystallization. During the preparation of the medicinal solution, two sterilization methods are adopted: 121°C high-pressure steam sterilization for 15 minutes and 0.22 μm microporous membrane. The injection of the present invention has stable physical and chemical properties and low impurity content , can be stored for a long time.

Owner:JINAN KANGHE MEDICAL TECH

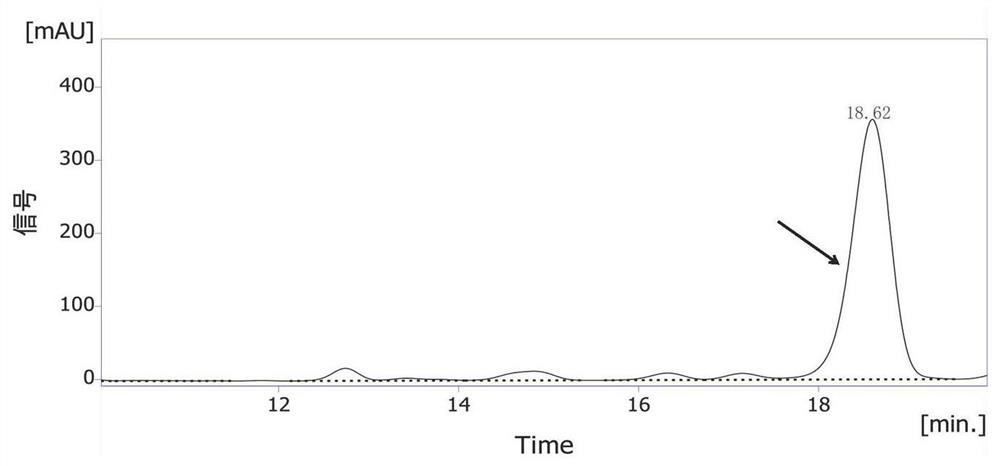

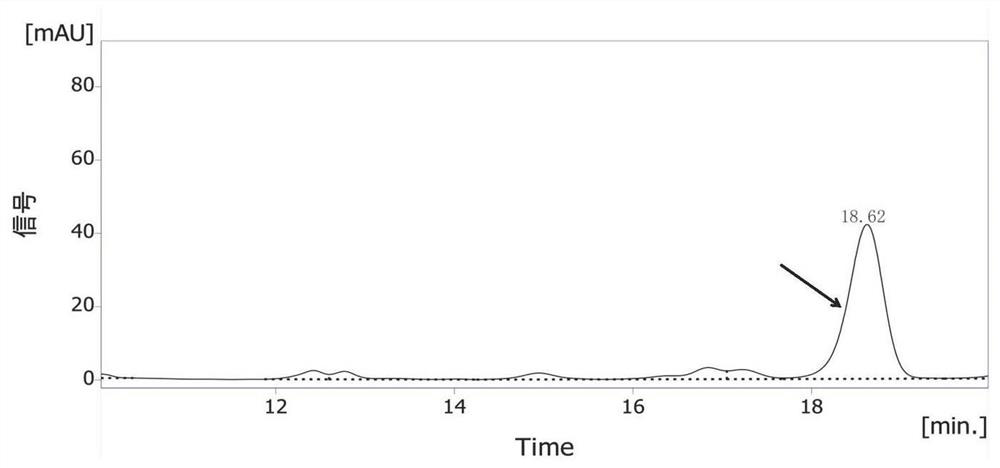

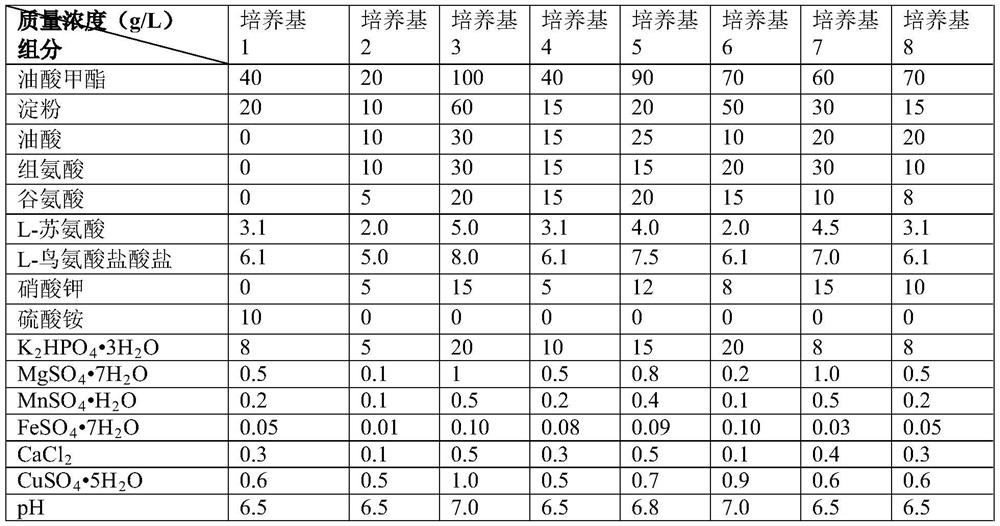

Echinocandin B synthetic medium and application

ActiveCN112646854AClear chemical compositionGood repeatabilityFungiMicroorganism based processesEchinocandin BThreonine

The invention discloses an echinocandin B synthetic medium and application of the echinocandin B synthetic medium in preparation of echinocandin B. The echinocandin B synthetic medium is prepared from, by mass concentration, 20-100g / L of methyl oleate, 10-60g / L of starch, 10-30g / L of oleic acid, 10-30g / L of histidine, 5-20g / L of glutamic acid, 2-5g / L of L-threonine, 5-8g / L of L-ornithine hydrochloride, 5-15g / L of potassium nitrate, 5-20g / L of K2HPO4.3H2O, 0.1-1g / L of MgSO4.7H2O, 0.1-0.5 g / L of MnSO4.H2O, 0.01-0.1g / L of FeSO4.7H2O, 0.1-0.5g / L of CaCl2, and 0.5-1g / L of CuSO4.5H2O, wherein water serves as a solvent, and pH is 6.5-7.0. The yield of echinocandin B reaches 1950mg / L.

Owner:ZHEJIANG UNIV OF TECH

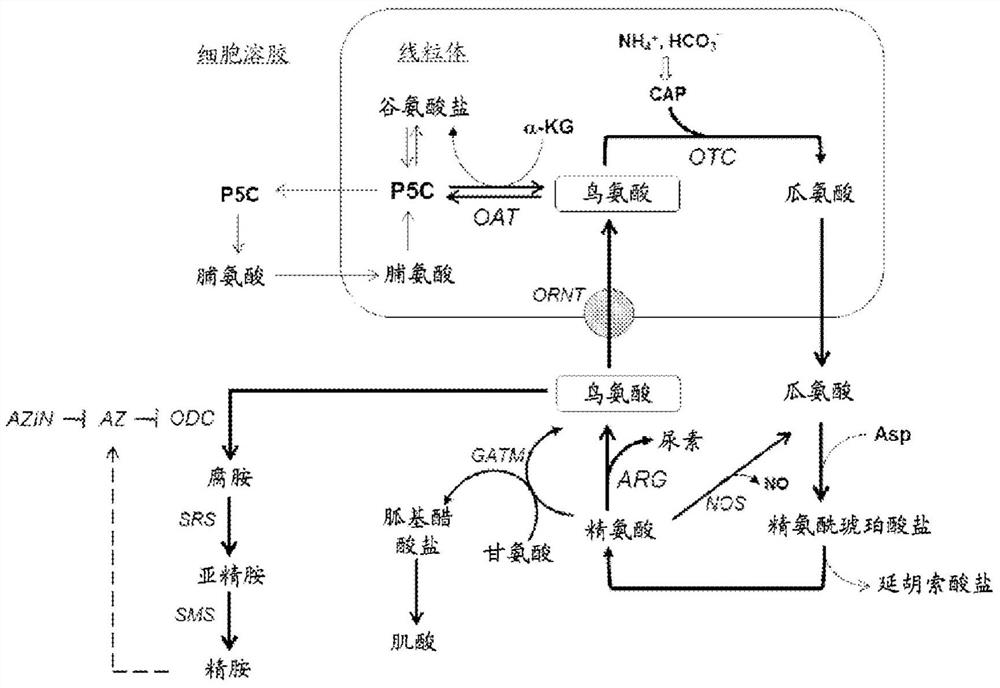

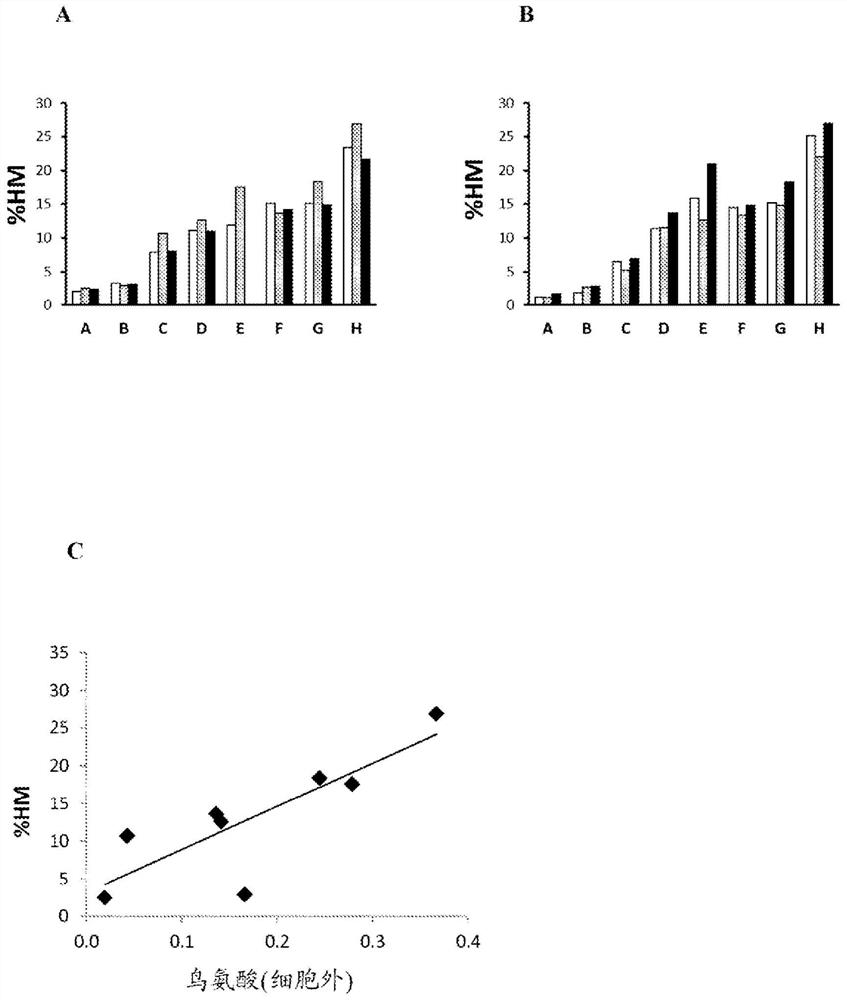

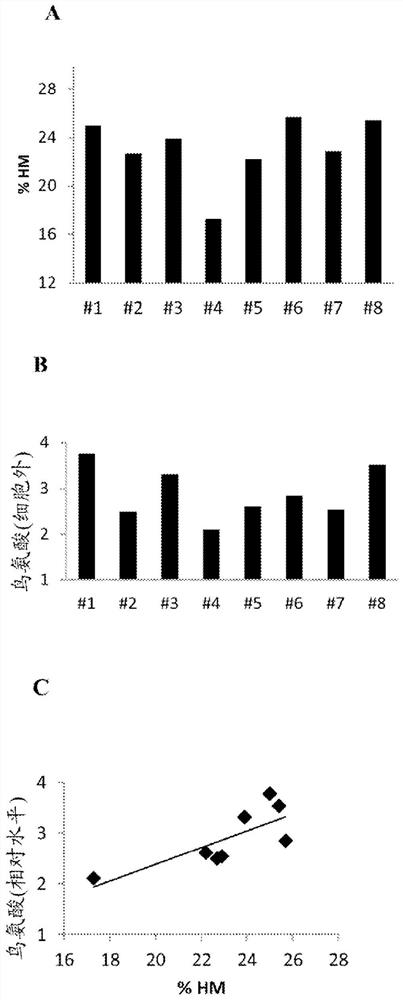

Modulation of ornithine metabolism to manipulate high mannose glycoform content of recombinant proteins

ActiveCN106029896BGenetically modified cellsCulture processHigh mannoseOrnithine-Oxo-Acid Transaminase

The present invention relates to a method for manipulating the high mannose glycoform content of recombinant glycoproteins by modulating ornithine metabolism during cell culture.

Owner:AMGEN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com