Preparation method of enzymolysis ovalbumin

An ovalbumin and enzymatic hydrolysis technology, applied in the production field of enzymatic ovalbumin, can solve the problems of increasing cost, time-consuming and laborious, and affecting the production efficiency of enzymatic ovalbumin, so as to ensure the production efficiency, prolong the storage period, and improve the enzymatic hydrolysis process. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

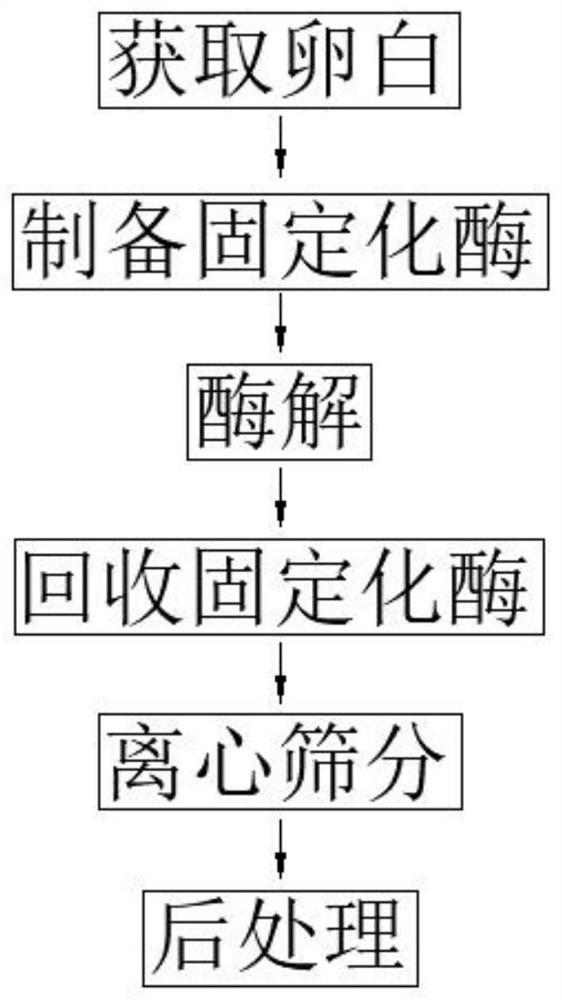

[0029] see figure 1 , the present invention provides a technical solution: a preparation method of enzymolyzed ovalbumin, the enzymolyzed ovalbumin is composed of the following raw materials in parts by weight: 0.21 parts of ornithine, 1.50 parts of lysine, 0.80 parts of histidine, 2.25 parts of arginine, 0.80 parts of threonine, 1.50 parts of serine, 1.41 parts of glutamic acid, 1.00 parts of proline, 0.30 parts of glycine, 1.86 parts of alanine, 2.20 parts of cystine, 3.32 parts of valine, 4.34 parts of leucine, 1.17 parts of isoleucine, 0.41 parts of tyrosine, 2.25 parts of phenylalanine, 1.03 parts of aspartic acid and 2.49 parts of methionine, and the balance is water; the preparation method of the enzymatic hydrolysis ovalbumin Specific steps are as follows:

[0030] Step 1: Obtain egg white: Soak the collected eggs until the sundries on the outer surface of the eggs are separated from the eggs, then remove the eggs, rinse them with clean water, sterilize them with disi...

Embodiment 2

[0040] see figure 1 , the present invention provides a technical solution: a preparation method of enzymolysis ovalbumin, a preparation method of enzymolysis ovalbumin, the enzymolysis ovalbumin is composed of the following raw materials in parts by weight: 0.36 parts of ornithine, lysine 3.75 parts of acid, 1.3 parts of histidine, 3.87 parts of arginine, 2.30 parts of threonine, 3.75 parts of serine, 4.82 parts of glutamic acid, 1.79 parts of proline, 1.64 parts of glycine, 3.51 parts of alanine, cystine 3.70 parts of acid, 5.67 parts of valine, 6.18 parts of leucine, 2.51 parts of isoleucine, 0.92 parts of tyrosine, 4.79 parts of phenylalanine, 1.73 parts of aspartic acid, 6.40 parts of methionine, and the balance is water; the specific steps of the preparation method of the enzymolysis ovalbumin are as follows:

[0041] Step 1: Obtain egg white: Soak the collected eggs until the sundries on the outer surface of the eggs are separated from the eggs, then remove the eggs, rins...

Embodiment 3

[0051] see figure 1 , the present invention provides a technical solution: a preparation method of enzymolysis ovalbumin, a preparation method of enzymolysis ovalbumin, the enzymolysis ovalbumin is composed of the following raw materials in parts by weight: 0.51 parts of ornithine, lysine 6.00 parts of acid, 1.80 parts of histidine, 5.50 parts of arginine, 3.80 parts of threonine, 6.00 parts of serine, 8.24 parts of glutamic acid, 2.58 parts of proline, 2.98 parts of glycine, 5.17 parts of alanine, cystine 5.20 parts of acid, 8.03 parts of valine, 8.03 parts of leucine, 3.86 parts of isoleucine, 1.44 parts of tyrosine, 7.33 parts of phenylalanine, 2.44 parts of aspartic acid, 8.40 parts of methionine, and the balance is water; the specific steps of the preparation method of the enzymolysis ovalbumin are as follows:

[0052] Step 1: Obtain egg whites: Soak the collected eggs until the sundries on the outer surface of the eggs are separated from the eggs, then remove the eggs, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com