System for processing exhaust gas, and method for processing exhaust gas

A technology for waste gas treatment and waste gas, which is applied in gas treatment, separation method, combustion method, etc., can solve the problem of uncontrollable NH generation ratio, etc., and achieve the effect of reducing the cost of drainage treatment and easy treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

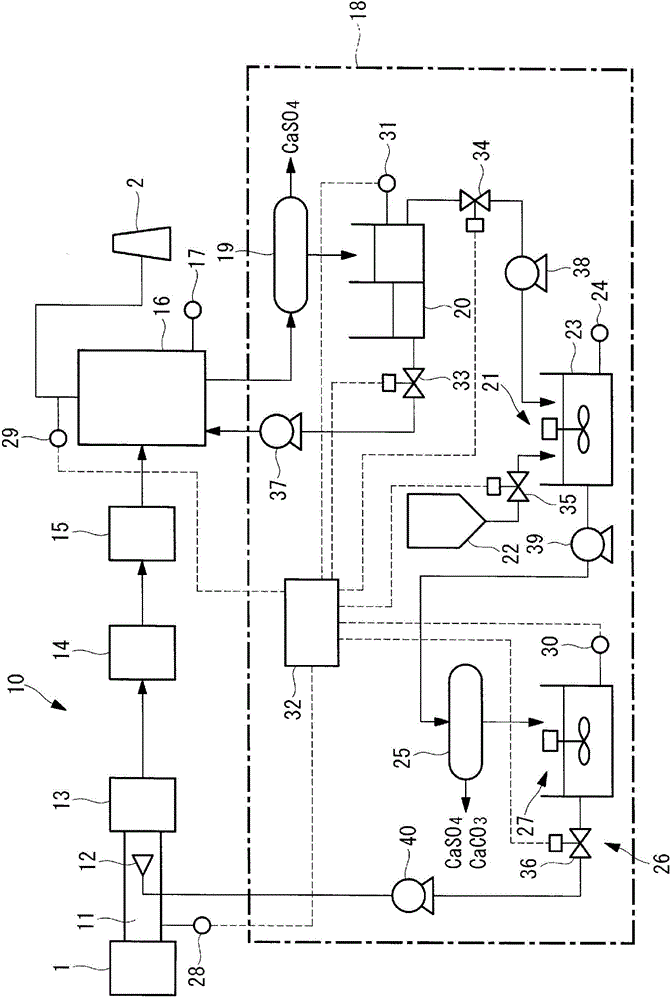

[0034] figure 1 is a schematic diagram of an exhaust gas treatment system according to an embodiment of the present invention. The exhaust gas treatment system 10 is installed on the gas downstream side of the boiler 1 . The boiler 1 is a combustion facility using coal or heavy oil as fuel.

[0035] The exhaust gas treatment system 10 includes a denitration device (denitration unit) 13 provided with a denitration catalyst inside, an air heater 14 for exchanging heat with the exhaust gas, a dust collector 15 for removing coal dust in the exhaust gas, and a wet exhaust gas treatment system in order from the upstream side of the exhaust gas. A desulfurization device (desulfurization unit) 16 and a circulation unit 18 . A chimney 2 is provided on the gas downstream side of the wet desulfurization device 16 .

[0036] In the flue 11 between the boiler 1 and the denitrification device 13 , there is provided a spraying unit 12 for spraying an aqueous solution containing ammonium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com