A composite modified hydration heat control material and its preparation method and application

A composite modification and heat of hydration technology, applied in the field of concrete admixtures, can solve the problems of not meeting the requirements of mass concrete, prolonging the setting time of concrete, reducing the strength of concrete, etc., and achieving high acid and alkali resistance and shear resistance. , The effect of improving freeze-thaw resistance and reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

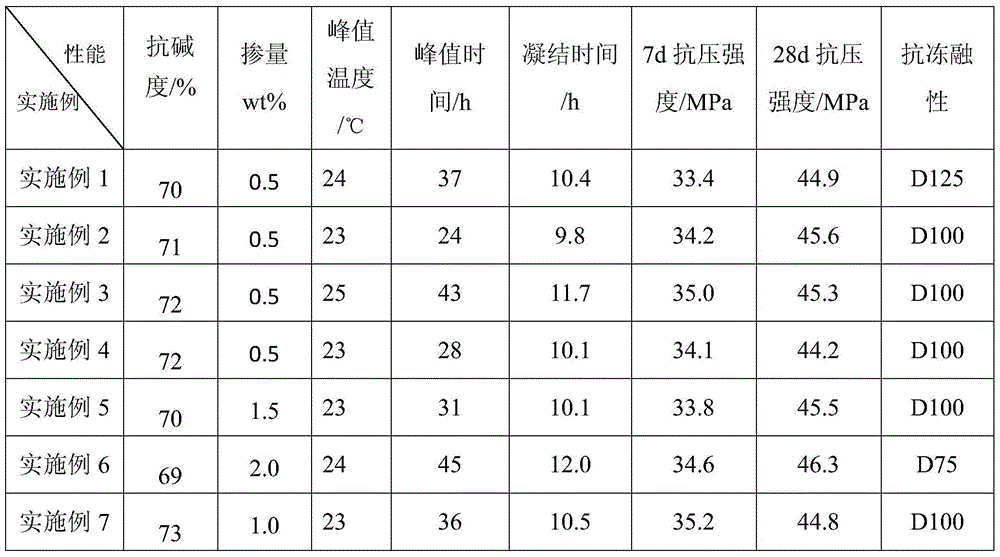

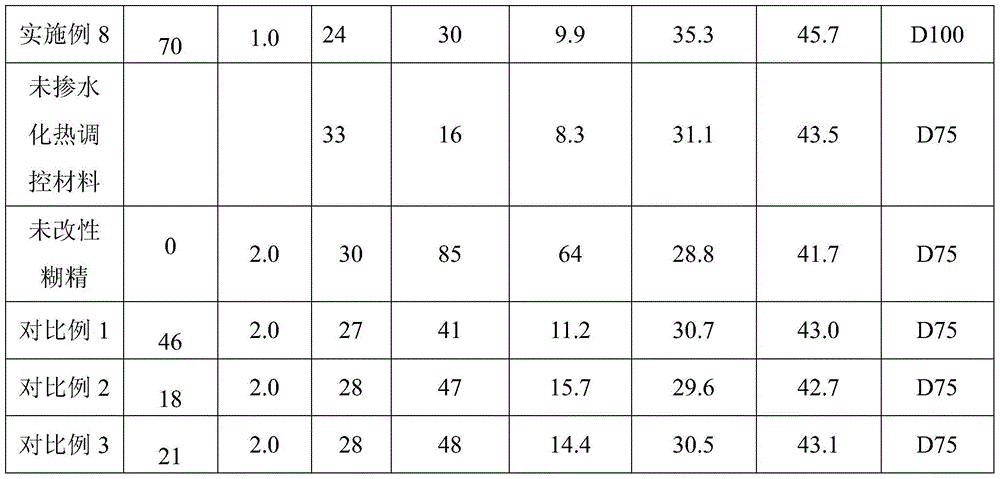

Examples

Embodiment 1

[0024] The preparation of the hydration heat regulating material includes the following steps: adding 100g of wheat starch into water to prepare a starch solution with a concentration of 30wt%, heating to 40°C and then adding 25g of hydrochloric acid and 1g of N,N'-methylenebisacrylamide React for 5 hours, adjust and maintain the pH value to 8 with sodium hydroxide, add 10 g of alkenyl succinic anhydride to react for 12 hours, adjust the pH value to 5 with hydrochloric acid, wash and concentrate, dry in an oven at 60 ° C for 20 hours, and sieve to obtain 80~ 100-mesh solid granular hydration heat control material product.

Embodiment 2

[0026] The preparation of the hydration heat regulating material comprises the following steps: adding 100g of cornstarch into water to prepare a starch solution with a concentration of 60wt%, heating the temperature to 60°C, and then adding 5g of hydrochloric acid and 3g of 1,6-hexanediol diacrylate to react 10h, adjust and maintain the pH value to 10 with sodium hydroxide, add 30g of alkenyl succinic anhydride to react for 5h, adjust the pH value to 5 with hydrochloric acid, wash and concentrate, dry in an oven at 60°C for 20h, and sieve to obtain 80-100 The object is a solid granular hydration heat regulating material product.

Embodiment 3

[0028] The preparation of the hydration heat regulating material comprises the following steps: adding 100g of potato starch into water to prepare a starch solution with a concentration of 50wt%, adding 10g of nitric acid and 3g of polyethylene glycol diacrylate (molecular weight 200 Polyethylene glycol diacrylate of -300 can realize the present invention) reaction 15h, adjust and maintain pH value to 10 with sodium hydroxide, add 20g alkenyl succinic anhydride reaction 10h, adjust pH value to 6 after washing with hydrochloric acid and Concentrate, dry in an oven at 60°C for 20 hours, and sieve to obtain a solid granular hydration heat regulating material product of 80 to 100 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com