A preparation method of nanocrystalline cellulose composite material, products made therefrom and uses thereof

A technology of nanocrystals and composite materials, applied in the field of composite material preparation, can solve the problems of poor performance of polylactic acid/nanocellulose composite materials, poor dispersion of polyethylene glycol/nanocellulose blends, and difficulty in dispersion , to achieve the effect of facilitating continuous production, avoiding easy agglomeration, and shortening operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 100 parts of deionized water, 5 parts of nanocrystalline cellulose and 10 parts of polyethylene glycol 600000, put them into a high-pressure homogenizer, and homogenize at 20 MPa for 10 minutes to obtain a dispersion suspension of nanocrystalline cellulose and polyethylene glycol 6000. The dispersed suspension was put into a lyophilizer, and lyophilized at -80° C. under a vacuum pressure of 10 Pa for 8 hours to obtain a blocky solid, which was pulverized into powder by a pulverizer.

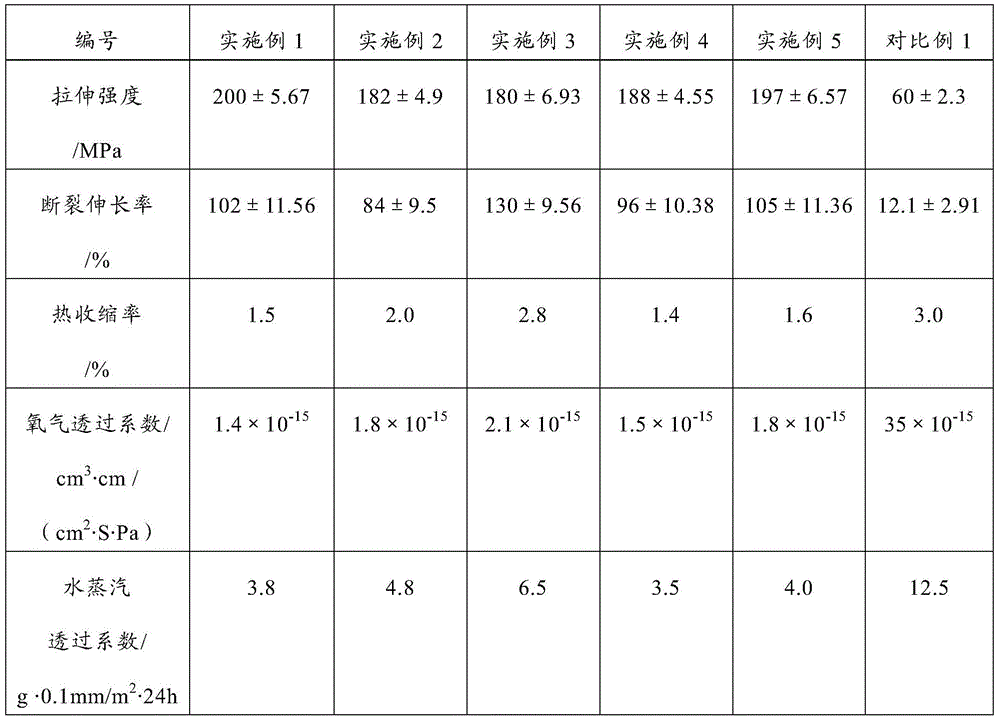

[0029] Add the obtained powder and 100 parts of polylactic acid resin to a twin-screw extruder for blending and granulation. The twin-screw extruder is multi-stage temperature-controlled. Speed 30rpm. The obtained particles are dried to remove moisture to obtain a nanocrystalline cellulose degradable composite material. The composite material was taken to prepare a test sample, and its physical and mechanical properties were tested. The test results are shown in Table 1.

Embodiment 2

[0031] Take 100 parts of deionized water, 4 parts of nanocrystalline cellulose and 8 parts of polyethylene glycol 60000, add them into a high-pressure homogenizer, and homogenize at 20 MPa for 10 minutes to obtain a dispersion suspension of nanocrystalline cellulose and polyethylene glycol 6000. The dispersed suspension was put into a lyophilizer, and lyophilized at -80° C. under a vacuum pressure of 10 Pa for 6 hours to obtain a blocky solid, which was pulverized into powder by a pulverizer.

[0032] Add the obtained powder and 100 parts of polylactic acid resin to a twin-screw extruder for blending and granulation. The twin-screw extruder is multi-stage temperature-controlled. Speed 30rpm. The obtained particles were dried to remove moisture to obtain a nanocrystalline cellulose degradable composite material. The composite material was taken to prepare a test sample, and its physical and mechanical properties were tested. The test results are shown in Table 1.

Embodiment 3

[0034] Take 100 parts of deionized water, 3 parts of nanocrystalline cellulose and 15 parts of polyethylene glycol 600015, put them into a high-pressure homogenizer, and homogenize at 20 MPa for 10 minutes to obtain a dispersion suspension of nanocrystalline cellulose and polyethylene glycol 6000. The dispersed suspension was put into a lyophilizer, and lyophilized at -80° C. under a vacuum pressure of 10 Pa for 8 hours to obtain a blocky solid, which was pulverized into powder by a pulverizer.

[0035] Add the obtained powder and 100 parts of polylactic acid resin to a twin-screw extruder for blending and granulation. The twin-screw extruder is multi-stage temperature-controlled. Speed 30rpm. The obtained particles were dried to remove moisture to obtain a nanocrystalline cellulose degradable composite material. The composite material was taken to prepare a test sample, and its physical and mechanical properties were tested. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com