Preparation method and application of polyurethane foam mixture capable of releasing carbon dioxide

A technology of polyurethane foam and mixture, which is applied in the preparation of polyurethane foam mixture and the application field of polyurethane foam. Good for heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] [Preparation of polyurethane foam mixture]

[0036] In this embodiment, the mixing process is first performed, adding polyurethane foam raw materials, polyethyleneimine and / or graft-modified polyethyleneimine into the storage tank, and mixing and stirring evenly to obtain CO-absorbable 2 wherein, by weight, the weight of the polyurethane foam raw material is 100 parts, and the weight of polyethyleneimine and / or graft-modified polyethyleneimine is 0.1 to 100 parts, and the polyurethane foam raw material does not contain isocyanate , but containing polyols as polyurethane soft segments.

[0037]In the present embodiment, the type of polyol is not particularly limited. In some examples, the polyol can be a polyol oligomer or a mixture thereof. In other examples, the polyol comprises polyether polyols, polyester polyols, polybutadiene diols, castor oil-based polyols, vegetable oil-derived polyols, vinyl polymer grafted polyether polyols, and barrier polyols. at least one...

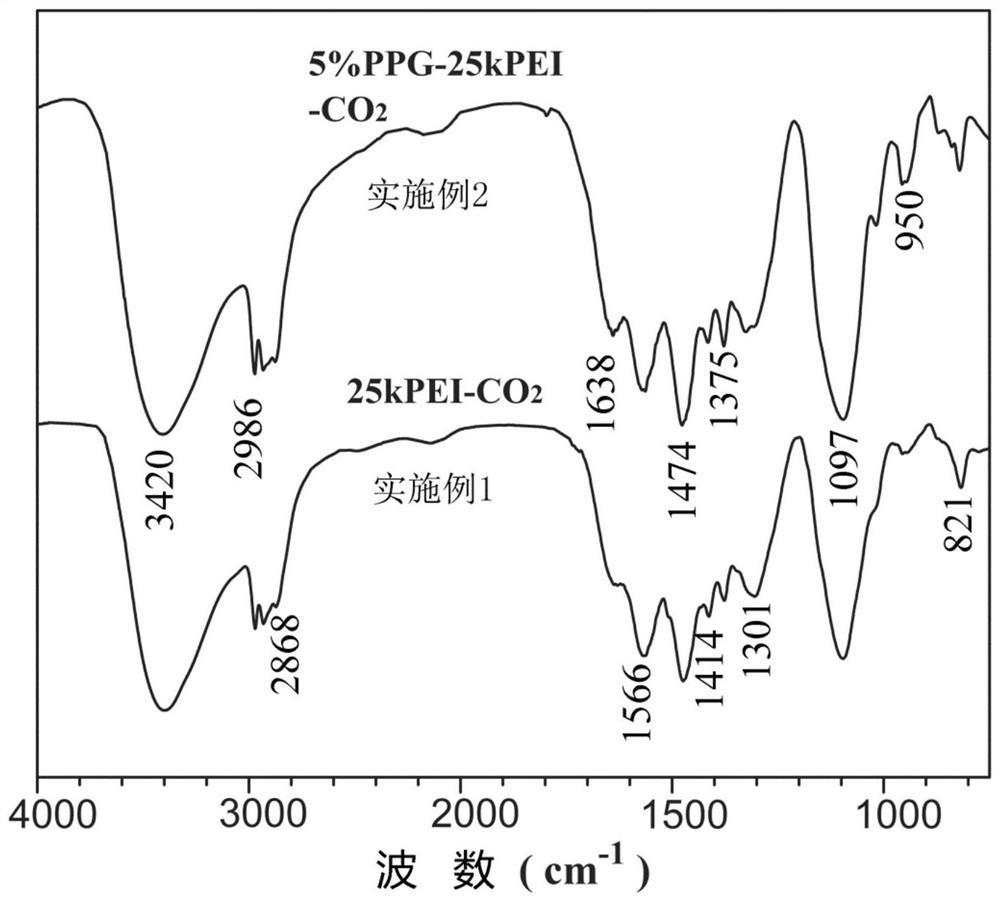

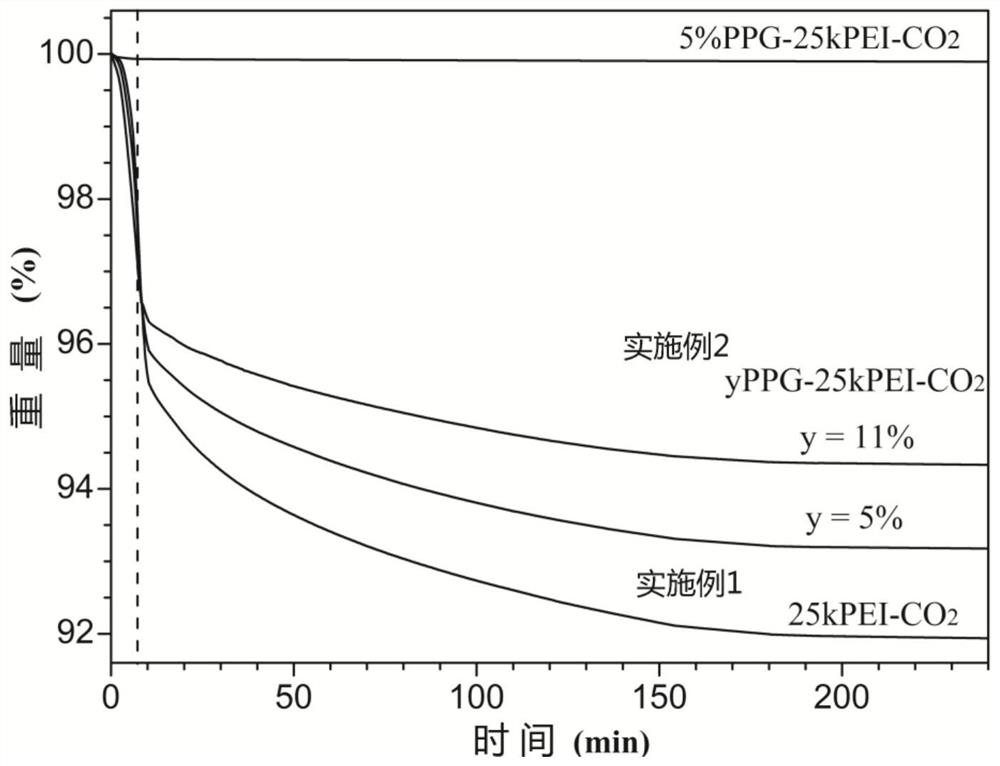

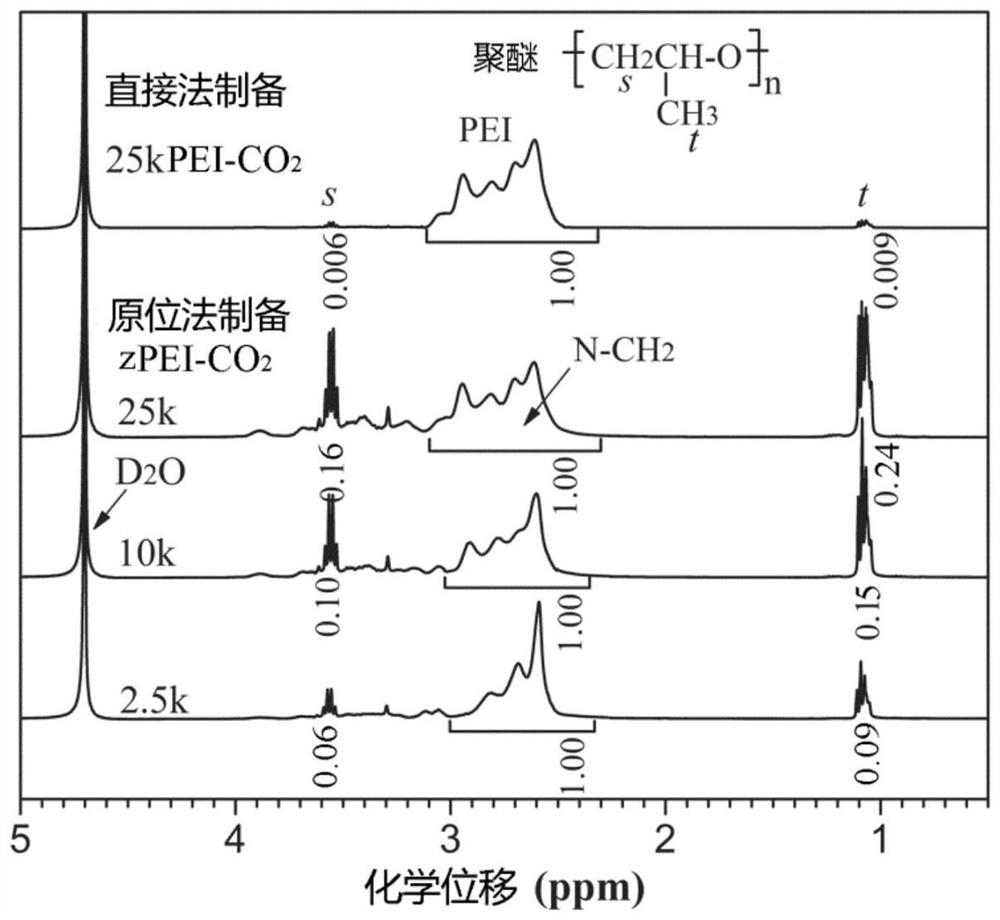

Embodiment 1)

[0056] In this example, PEI and polyether polyols are used as raw materials to prepare PEI-containing CO 2 Polyurethane foaming mixtures of adduct blowing agents and are used in the preparation of polyurethane foams. Add 100 kg of the two polyether mixtures (as shown in Table 1) into the storage tank, add 21.74 kg of branched PEI with different molecular weights, stir evenly, and keep the temperature at room temperature (25 °C) to obtain the absorbable CO 2 mixture; will be able to absorb CO 2 The mixture is transported to the pipeline reactor through a pressurized pump, and the liquid CO 2 Added into the pipeline reactor through a metering pump, the two reaction raw materials are fully mixed and reacted in the mixer, and sprayed into the polyurethane foaming mixture storage tank through the discharge port; the temperature of the material in the pipeline reactor is 25 ° C, and the pressure is 6.5 MPa; CO 2 The total amount added is 0.511 times the weight of PEI (that is, th...

Embodiment 2)

[0069] In this example, graft-modified PEI and polyether polyols were used as raw materials to prepare PEI-containing CO 2 The polyurethane foaming mixture of adduct blowing agent, and is used for preparing polyurethane foam, and wherein, graft modifier is dipropylene glycol methyl ether glycidyl ether (PPG-EPO, M n = 204.3 Daltons). First prepare the graft-modified PEI, taking the grafting degree of 5% as an example, add 20 kg PEI (containing 453.8 mol N, the source of PEI is the same as Table 1) into the reactor, and then add the corresponding grafting degree to calculate 4.636 kg of PPG-EPO (that is, 453.8 × 5% = 22.69 mol), and then add 30 L of absolute ethanol as a solvent, and react at 50 °C for 8 h. After the reaction, ethanol was distilled off under reduced pressure at 50°C, and then ethanol was removed under high vacuum at 50°C for 5 h to obtain the product 5%PPG-zPEI (z = 2.5k, 10k or 25k) with 5% grafting degree. The synthesis method of PEI with other grafting de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com