A kind of environment-friendly asphalt pavement regeneration agent, biomass dispersant and preparation method

A kind of technology of asphalt pavement and regeneration agent, which is applied in the direction of building structure, building insulation materials, building components, etc., can solve the problems of poor permeability, insufficient performance indicators, high dependence on petroleum resources, etc., and achieve excellent dispersion and lubrication, raw materials Wide range of sources, the effect of improving high temperature stability and crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present embodiment provides a kind of preparation method of biomass dispersant, and this method comprises the following steps:

[0043] Step S1, drying the soybean oil residues, peanut oil residues and rapeseed oil residues in the edible oil processing process and mixing them evenly in a weight ratio of 1:2:2 to obtain biomass residues;

[0044] In step S2, potassium carbonate and sodium fluoride are uniformly mixed in a weight ratio of 2:1, and then calcined to obtain a solid alkali catalyst;

[0045]Step S3, injecting 200 parts of methanol solution with a weight concentration of 60%, 100 parts of biomass residue and 8 parts of solid alkali catalyst into the reactor for reaction, and then separating the solid alkali catalyst, the mixture is statically layered, and the upper oil phase is washed Filtration to obtain a biomass dispersant.

[0046] Specifically, in step S2, the specific process of the calcination is: under the protection of nitrogen, place the calcina...

Embodiment 2

[0050] This embodiment provides an environment-friendly asphalt pavement regeneration agent, which is made of the following raw materials in parts by weight: 58 parts of biomass dispersant, 4 parts of anti-aging agent, 8 parts of plasticizer and modified The dosage is 30 parts.

[0051] Specifically, the biomass dispersant is prepared by the preparation method of the biomass dispersant in Example 1.

[0052] Specifically, the anti-aging agent is made by mixing dibutyl hydroxytoluene, hydroxyphenyl substituted benzotriazole and light calcium carbonate in a weight ratio of 2:1:1;

[0053] Specifically, the plasticizer is made by mixing phenyl petroleum sulfonate and diisodecyl phthalate in a weight ratio of 3:1;

[0054] Specifically, the modifier is prepared by mixing polyethylene glycol monooleate, ethylene bisstearamide and ethylene-acrylate-glycidyl methacrylate in a weight ratio of 1:2:1.5.

[0055] The specific process of the preparation method of the environment-friendl...

Embodiment 3

[0058] This embodiment provides an environment-friendly asphalt pavement regeneration agent, which is made of the following raw materials in parts by weight: 70 parts of biomass dispersant, 4 parts of antiaging agent, 6 parts of plasticizer and modified The dosage is 20 parts.

[0059] Specifically, the biomass dispersant, anti-aging agent, plasticizer and modifier are the same as in Example 2.

[0060] The preparation method of the environment-friendly asphalt pavement regeneration agent of this embodiment is basically the same as that of Embodiment 2.

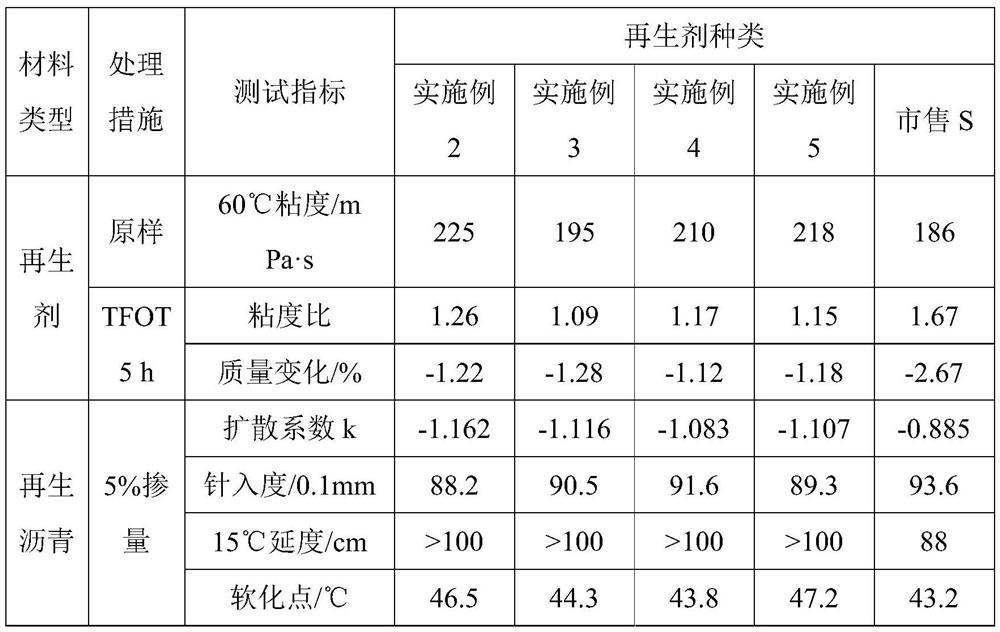

[0061] See Table 1 for the performance test results of this embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com