A low-temperature adhesive self-adhesive varnish for transposition wires of transformers

A technology of transposition wire and self-adhesive paint, which is applied in the direction of coil manufacturing, coating, epoxy resin coating, etc., can solve the problem of not being able to meet the low temperature bonding of transposition wire of ultra-high voltage and ultra-high voltage transformers, and achieve improvement The effect of sudden short-circuit resistance, improved integrity and mechanical strength, and low thermal bonding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

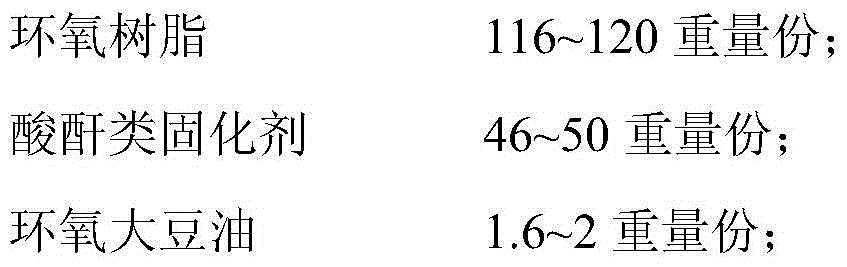

[0030] The self-adhesive paint disclosed in this embodiment comprises the following raw material components in parts by weight:

[0031]

[0032] The number average molecular weight of the epoxy resin is 5000-8000.

[0033] The softening point of the epoxy resin is 140-150°C.

[0034] The acid anhydride curing agent is 3-methyltetrahydrophthalic anhydride.

[0035] The leveling agent is selected from polyacrylate; the number average molecular weight of the polyacrylate is 5000-6000.

Embodiment 2

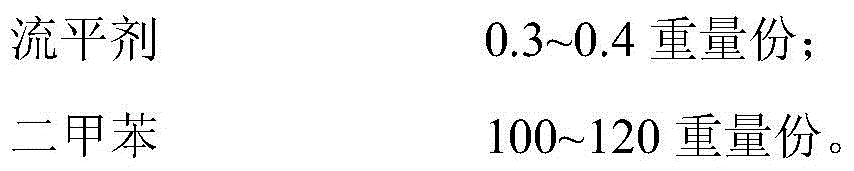

[0037] The self-adhesive paint disclosed in this embodiment comprises the following raw material components in parts by weight:

[0038]

[0039] The number average molecular weight of the epoxy resin is 5000-8000.

[0040] The softening point of the epoxy resin is 140-150°C.

[0041] The acid anhydride curing agent is 4-methyltetrahydrophthalic anhydride.

[0042] The leveling agent is selected from polyacrylate; the number average molecular weight of the polyacrylate is 5000-6000.

Embodiment 3

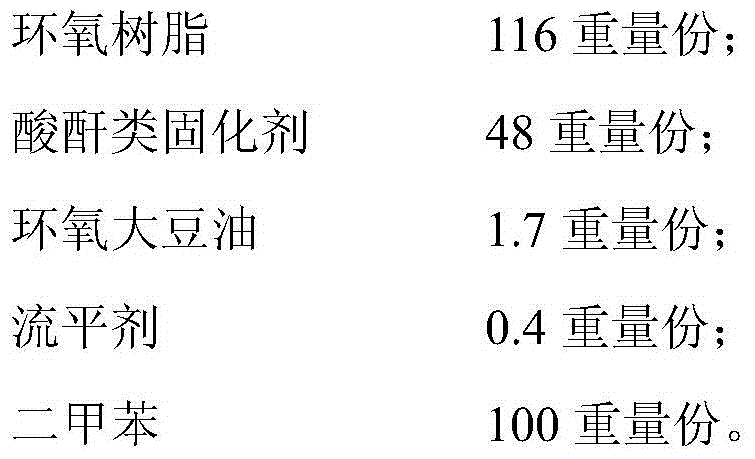

[0044] The self-adhesive paint disclosed in this embodiment comprises the following raw material components in parts by weight:

[0045]

[0046]

[0047] The number average molecular weight of the epoxy resin is 5000-8000.

[0048] The softening point of the epoxy resin is 140-150°C.

[0049] The acid anhydride curing agent is methyl hexahydrophthalic anhydride.

[0050] The leveling agent is selected from polyacrylate; the number average molecular weight of the polyacrylate is 5000-6000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com