Sealing glue under pressure

A technology for plugging leaks under pressure and liquid nitrile rubber, which is applied in the directions of adhesives, adhesive types, adhesive additives, etc. Due to problems such as the poor hardness of the plugging glue, it can achieve a wide range of applicable media, better plugging effect, and timely plugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

[0010] The production process of pressure plugging glue is as follows:

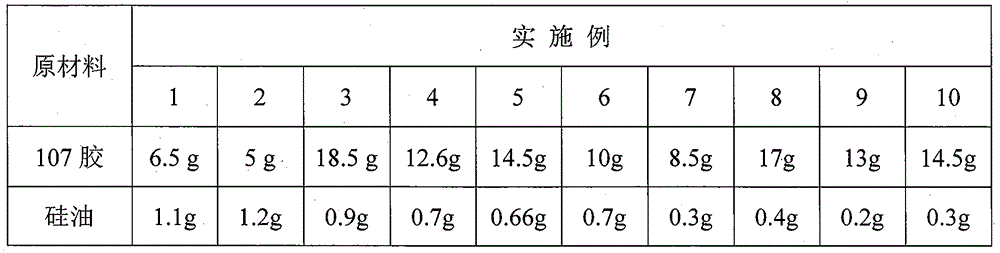

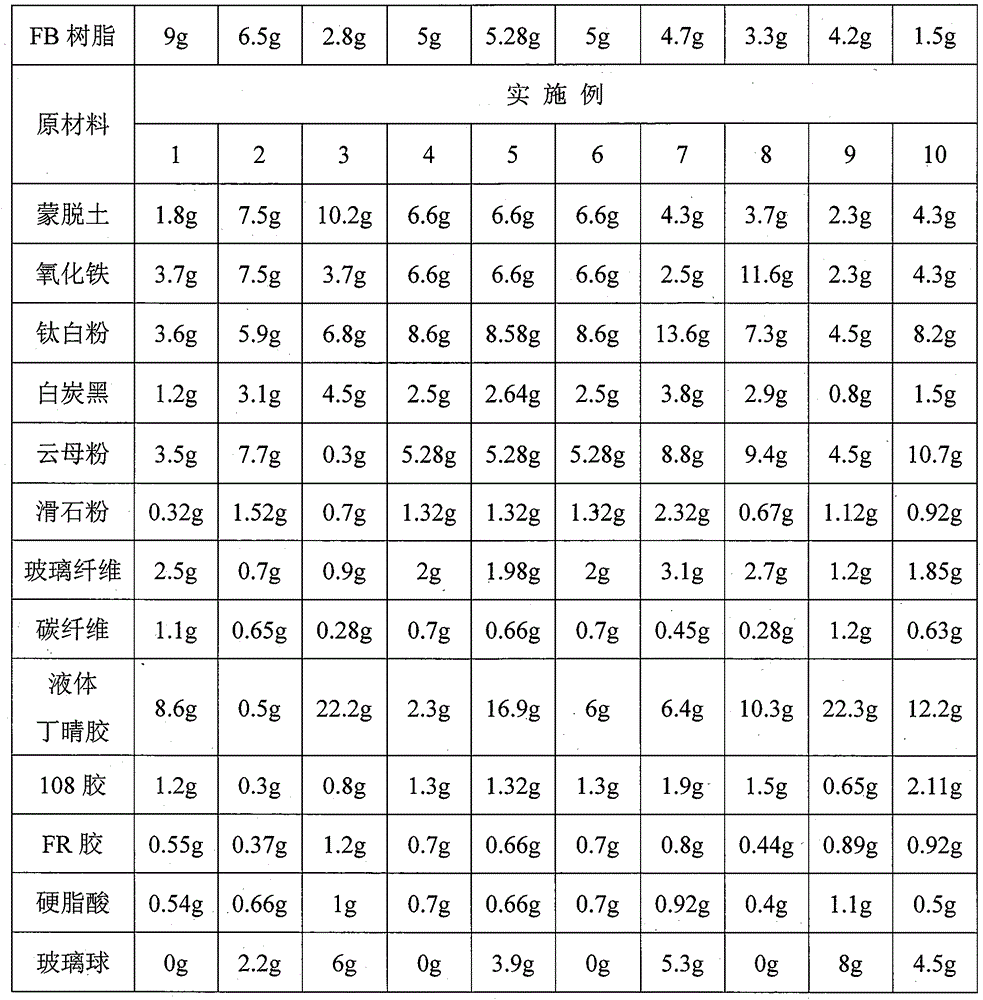

[0011] (1) Take each raw material respectively according to the consumption in Table 1;

[0012] (2) Put the raw materials that have been weighed into the same container, and use a metal rod or a mixer for simple mixing. Then, put all the raw materials after the simple mixing on the open mill, and fully mix the raw materials. The uniform raw materials are put into the inlet of the extruder, and the cylindrical semi-finished products with different lengths and diameters of 21mm are extruded with the equal pressure of the extruder;

[0013] (3) Place the prepared semi-finished product on the board to lower the temperature of the product, and then cut the semi-finished product with different lengths into black cylindrical glue sticks with a diameter of 21mm and a length of 90mm according to the actual length. The product making process is over.

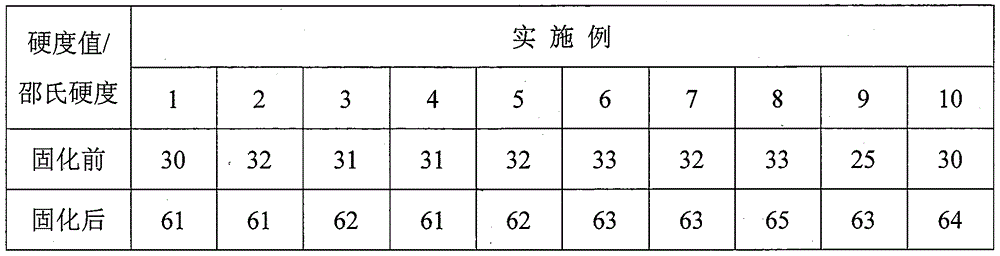

[0014] Table 1 Example 1-10 formulation

[0015]

[0016...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com