A New Electroluminescent Material and Its Application

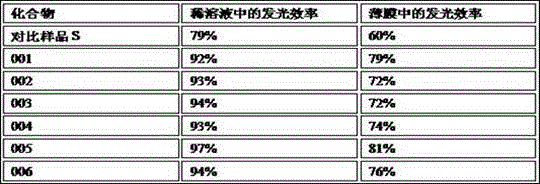

An electroluminescent material and luminescent technology, applied in the direction of luminescent materials, condensation/addition reaction preparation of amino compounds, chemical instruments and methods, etc., can solve the problems that luminescent materials cannot meet the requirements of OLED, and achieve a good planar structure and conjugated systems, improved lifetime, and simple synthesis and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

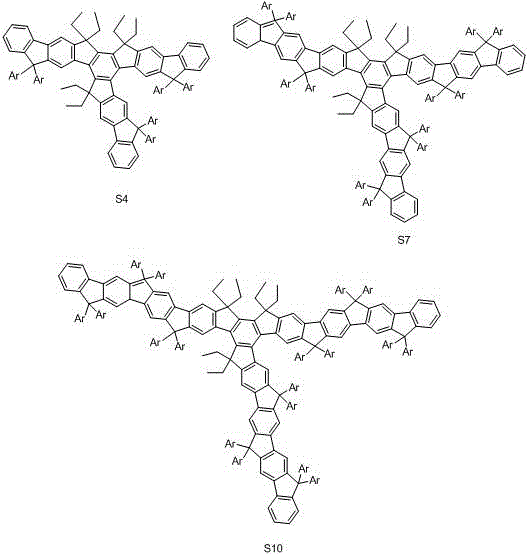

Image

Examples

Embodiment 1

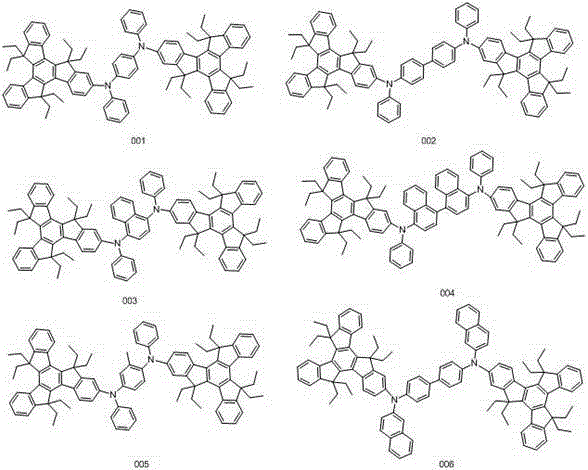

[0033] Embodiment 1: the synthesis of compound 001

[0034] The specific synthetic route is shown in the following formula:

[0035]

[0036] Under the condition of nitrogen protection, add 10.81g of phenylenediamine, 47.10g of bromobenzene, 0.75g of tris(dibenzylideneacetone)dipalladium, 2,2,-bis(diphenylphosphine)-1,1 into a 300ml single-necked bottle ,-binaphthyl (BINAP) 1.05g, potassium tert-butoxide 10.5g, dehydrated toluene 200ml, react at 85°C for 6 hours. After cooling, the reaction solution was filtered, and the obtained crude product was purified by silica gel chromatography, and dried under reduced pressure to obtain 24.73 g of a white solid intermediate.

[0037] 168.05g of 2-bromo-5,5,10,10,15,15-hexaethyl-10,15-dihydro-5H-indenofluorene, 24.73g of white solid intermediate, 21.32g of potassium tert-butoxide, 1.02 g of palladium (II) acetate, 0.97 g of tri-tert-butylphosphine, and 250 ml of dehydrated toluene were reacted at 85°C for 10 hours. The reaction so...

Embodiment 2

[0038] Embodiment 2: the synthesis of compound 002

[0039] The specific synthetic route is shown in the following formula:

[0040]

[0041]Under the condition of nitrogen protection, add 18.40g of phenylenediamine, 47.10g of bromobenzene, 1.50g of tris(dibenzylideneacetone)dipalladium, 2,2,-bis(diphenylphosphine)-1, 2.1g of 1,-binaphthyl (BINAP), 21.1g of potassium tert-butoxide, and 200ml of dehydrated toluene were reacted at 86°C for 7 hours. After cooling, the reaction solution was filtered, and the obtained crude product was purified by silica gel chromatography, and dried under reduced pressure to obtain 30.27 g of a white intermediate.

[0042] 173.65g of 2-bromo-5,5,10,10,15,15-hexaethyl-10,15-dihydro-5H-indenofluorene, 30.27g of white intermediate, 22.44g of potassium tert-butoxide, acetic acid 1.08 g of palladium (II), 1.01 g of tri-tert-butylphosphine, and 250 ml of dehydrated toluene were reacted at 86°C for 11 hours. The reaction solution was filtered, and ...

Embodiment 3

[0043] Embodiment 3: the synthesis of compound 003

[0044] The specific synthetic route is shown in the following formula:

[0045]

[0046] Under the condition of nitrogen protection, add 15.82g of naphthalene diamine, 47.10g of bromobenzene, 1.50g of tris(dibenzylideneacetone)dipalladium, 2,2,-bis(diphenylphosphine)-1,1 into a 300ml one-port bottle 2.1 g of -binaphthyl (BINAP), 21.1 g of potassium tert-butoxide, and 200 ml of dehydrated toluene were reacted at 86°C for 6 hours. After cooling, the reaction solution was filtered, and the obtained crude product was purified by silica gel chromatography, and dried under reduced pressure to obtain 28.56 g of a white intermediate.

[0047] 2-Bromo-5,5,10,10,15,15-hexaethyl-10,15-dihydro-5H-indenofluorene 179.25g, white intermediate 28.56g, potassium tert-butoxide 23.56g, acetic acid 1.14 g of palladium (II), 1.06 g of tri-tert-butylphosphine, and 250 ml of dehydrated toluene were reacted at 87°C for 12 hours. The reaction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com