Ground source heat pump deep well backfill grouting method

A technology of backfill grouting and ground source heat pump, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems that ground source heat pump technology cannot be realized, construction quality is difficult to guarantee, and heat exchange effect is poor, so as to improve the construction continuity High performance, high construction efficiency and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

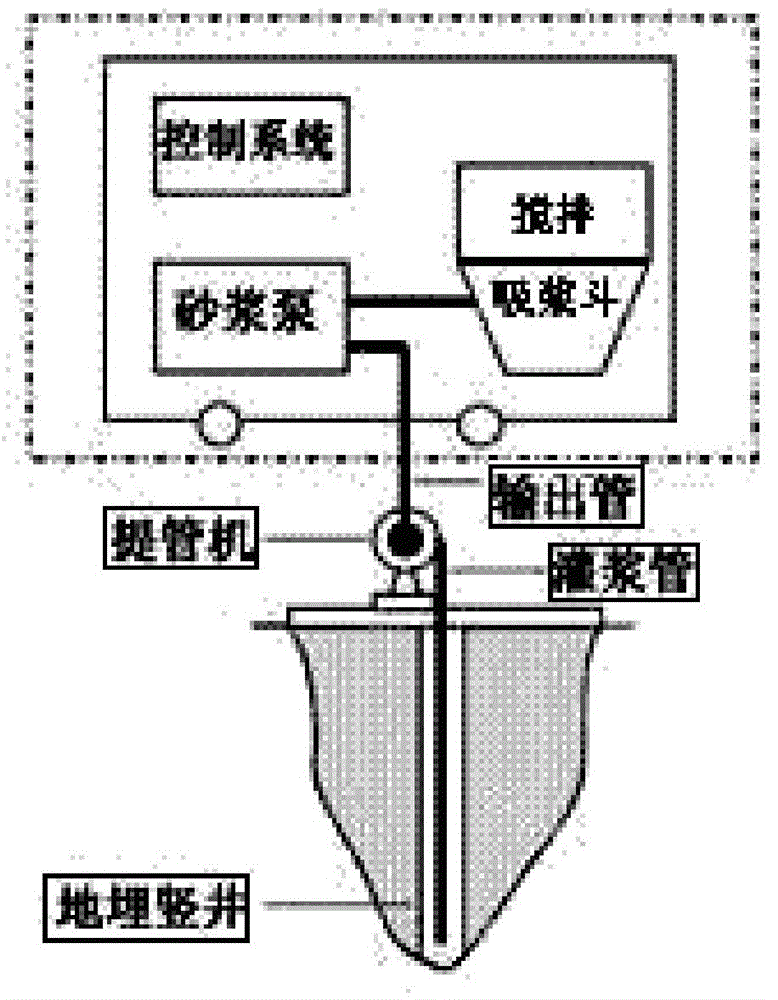

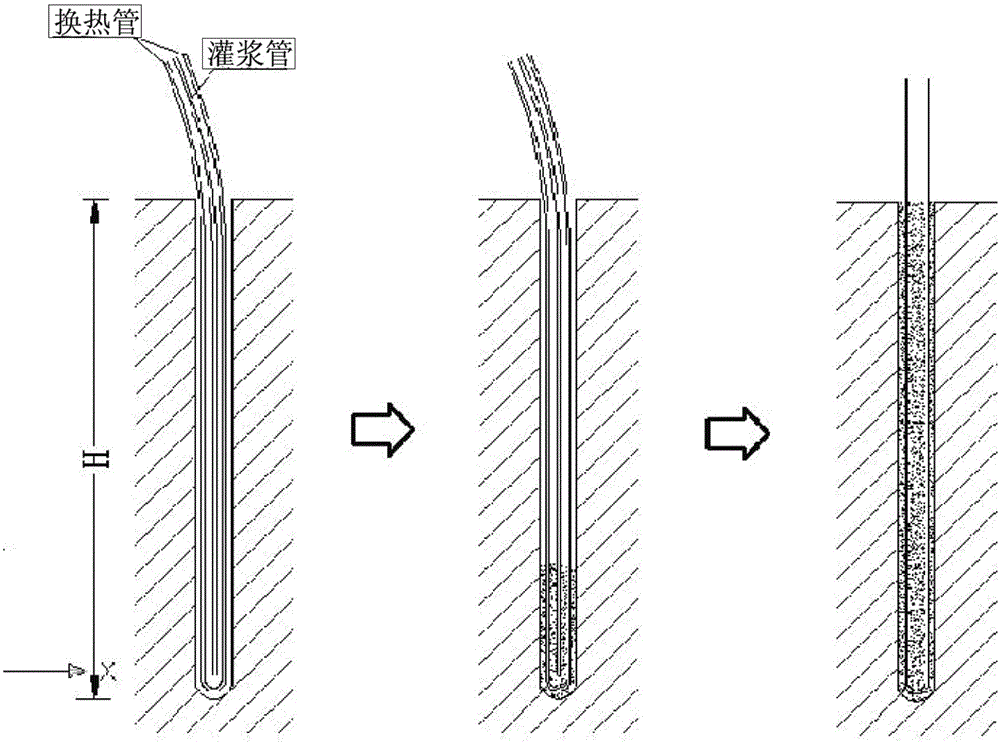

[0028] see Figure 1-2 , The invention provides a ground source heat pump deep well backfill grouting method. This method is also known as back-pressure backfill grouting method of long tubes of ground source heat pump deep wells, which can realize dense backfill grouting without hollowing, greatly improves the heat exchange capacity of deep heat exchange wells, and effectively guarantees the quality of ground source heat pump systems. The ground source heat pump deep well backfill grouting method preferably includes the following steps:

[0029] After setting the heat exchange tubes in the deep well or at the same time, insert the long grouting pipe into the bottom of the deep well;

[0030] The backfilling slurry is transported to the bottom of the deep well by the mortar delivery pump (or called the mortar pump) through a long pipe, and the grouting backfills the shaft from the bottom, and the slurry liquid level gradually overflows to form a back pressure;

[0031] When ...

Embodiment 2

[0057] See you again Figure 1-2 , which shows a schematic diagram of the ground source heat pump deep well backfill grouting equipment and method according to a preferred embodiment of the present invention. Preferably, the ground source heat pump deep well backfill grouting method adopts a back pressure backfill construction mode, using a long pipe to insert into the bottom of the deep well, and the backfill slurry is transported to the bottom of the heat exchange deep well by the mortar delivery pump through the long rubber hose, and grouted from the bottom to fill the well with back pressure , the slurry liquid level gradually overflows to form a back pressure. When the slurry liquid level overflows to about 10 meters from the outlet of the grouting pipe, use the pipe lifter to start lifting the grouting pipe. The machine can rotate to wind the pipe and lift it up. It realizes filling while lifting, and the grouting speed matches the pipe lifting speed. Always ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com