Organic light-emitting device and production method thereof

An electroluminescent device and luminescent technology, which is applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of reduced luminous efficiency, low electron transmission rate, unfavorable electron injection, etc., and achieve enhanced transmission rate , Improve light extraction efficiency, strengthen the effect of scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The method for preparing the above-mentioned organic electroluminescent device specifically includes the following steps:

[0035] 1. Rinse the glass with distilled water and ethanol, and soak it in isopropanol overnight.

[0036] 2. Prepare a conductive anode film on the glass cleaned in the above steps to obtain an anode conductive substrate, and then vapor-deposit sequentially on the anode conductive substrate to prepare a hole injection layer, a hole transport layer, a light-emitting layer, and an electron transport layer.

[0037] 3. Next, an electron injection layer is prepared on the above electron transport layer, and the electron injection layer is composed of an organic silicon small molecule layer, a rubidium compound doped layer and a titanium dioxide layer. The organic silicon small molecule layer (organic silicon small molecule material with an energy gap of -3.5~-5.5eV) is evaporated by thermal resistance, and the organic silicon small molecule layer is d...

Embodiment 1

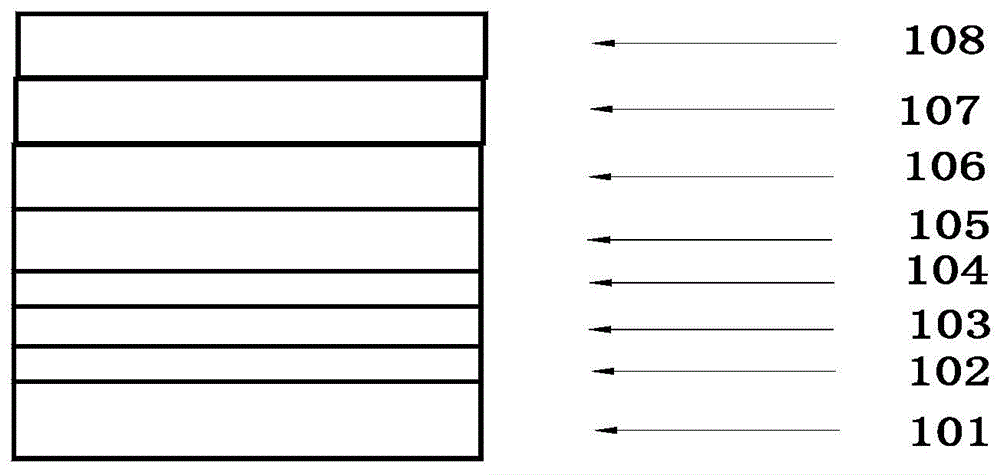

[0050] like figure 1 As shown, the organic electroluminescent device in this embodiment is a layered structure, and each layer is in turn:

[0051] Anode conductive substrate 101 of glass / IZO, MoO 3 The hole injection layer 102 of material, the hole transport layer 103 of TAPC material, the light-emitting layer 104 of ADN material, the electron transport layer 105 of TPBI material, the organosilicon small molecule layer 106 of UGH2 material, Rb 2 CO 3 :CsN 3 Rubidium compound doped layer 107, titanium dioxide layer 108, and cathode layer 109 made of Ag. The organic silicon small molecule layer 106, the rubidium compound doped layer 107 and the titanium dioxide layer 108 form an electron injection layer. (where the slash " / " indicates a layered structure, and the colon ":" indicates mutual doping)

[0052] The above-mentioned organic electroluminescent device is prepared according to the following steps in sequence:

[0053] 1. Rinse the glass with distilled water and eth...

Embodiment 2

[0066] The layered structure of the organic electroluminescent device of the following examples 2-4 is basically the same as that of the example 1, so no illustration will be given here.

[0067] The organic electroluminescent device in this embodiment is a layered structure, and each layer is sequentially:

[0068] Anode conductive substrate of glass / IZO, V 2 o 5 Hole injection layer made of NPB material, hole transport layer made of NPB material, light emitting layer made of DCJTB material, electron transport layer made of TPBI material, organic silicon small molecule layer made of UGH1 material, rubidium compound doped layer made of RbCl:CsF material, titanium dioxide layer And the cathode layer of Pt material. The organic silicon small molecule layer, the rubidium compound doped layer and the titanium dioxide layer form the electron injection layer. (where the slash " / " indicates a layered structure, and the colon ":" indicates mutual doping)

[0069] The above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com