Graphene-coated amorphous nanoflower copper vanadate and its preparation method and application

A technology of graphene coating and copper vanadate, which is applied in the field of nanomaterials and electrochemistry, can solve the problems of structural damage, low conductivity of copper vanadate, limiting development and application, etc., so as to improve the conductivity of materials and benefit the market The effects of chemical promotion and electrochemical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

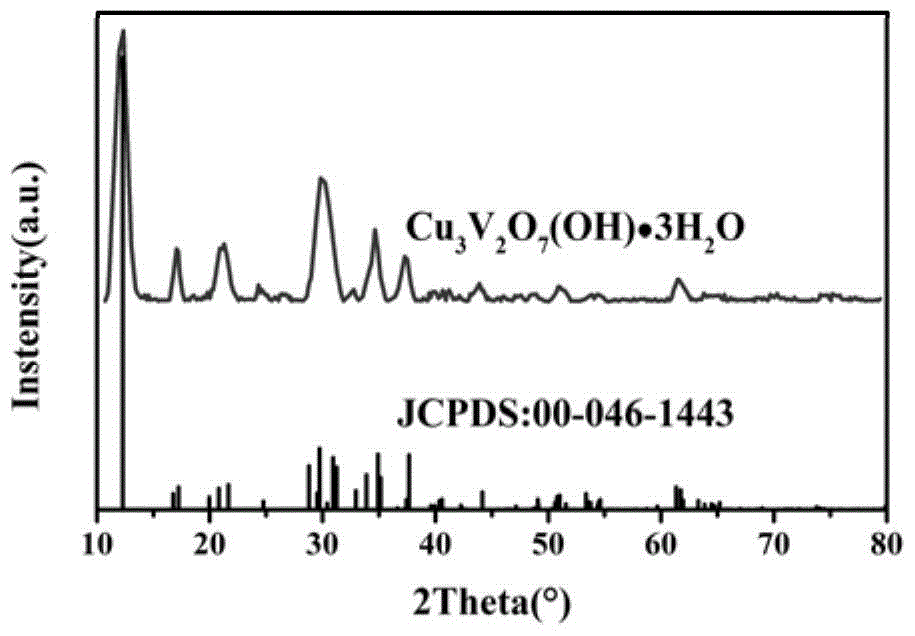

[0030] The preparation method of the amorphous nano-copper vanadate coated with graphene comprises the following steps:

[0031] 1) Add 1 g of polyvinylpyrrolidone (PVP) labeled K-30 and 0.1208 g of copper nitrate dihydrate into 50 ml of deionized water, and stir;

[0032] 2) Add 30 ul of hydrazine hydrate with a mass concentration of 80% to the solution obtained in step 1), and continue stirring for 40 minutes;

[0033] 3) Centrifuge the product obtained in step 2), wash it repeatedly with deionized water, disperse it into 200ml of deionized water, add 50ml of 0.02mM ammonium metavanadate solution and 6.8mg of graphene solution, and stir for 20h;

[0034] 4) Centrifuge the product obtained in step 3), wash it repeatedly with deionized water and ethanol, and finally place it in a 70°C oven for drying, and then put it in a vacuum oven for 30 minutes at 250°C to obtain a graphene package. Coated amorphous copper vanadate nanoparticles.

[0035] Taking the graphene-coated amorp...

Embodiment 6

[0072] The preparation method of the amorphous nano-copper vanadate coated with graphene comprises the following steps:

[0073] 1) Add 1 g of K-30 polyvinylpyrrolidone (PVP) and 0.1208 g of copper nitrate dihydrate into 50 ml of deionized water, and stir;

[0074] 2) Add 30 ul of hydrazine hydrate with a mass concentration of 80% to the solution obtained in step 1), and continue stirring for 40 minutes;

[0075] 3) Centrifuge the product obtained in step 2), wash it repeatedly with deionized water, disperse it into 200ml of deionized water, add 50ml of 0.02mM ammonium metavanadate solution and 6.8mg of graphene solution, and stir for 20h;

[0076] 4) Centrifuge the product obtained in step 3), wash it repeatedly with deionized water and ethanol, and finally place it in a 70°C oven for drying, and then put it in a vacuum oven for 30 minutes at 200°C to obtain a graphene package. Coated amorphous copper vanadate nanoparticles.

[0077] Taking the graphene-coated amorphous nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com