Method, system and method for processing bipolar plate of low-contact resistor and bipolar plate of low-contact resistor

A technology of low contact resistance and processing equipment, which is applied to fuel cell parts, regenerative fuel cells, collectors/separators, etc., can solve the problems of high contact internal resistance and reduce the contact internal resistance of bipolar plates and electrodes, etc. Achieve the effect of increasing discharge power, improving discharge power and voltage efficiency, and reducing contact internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

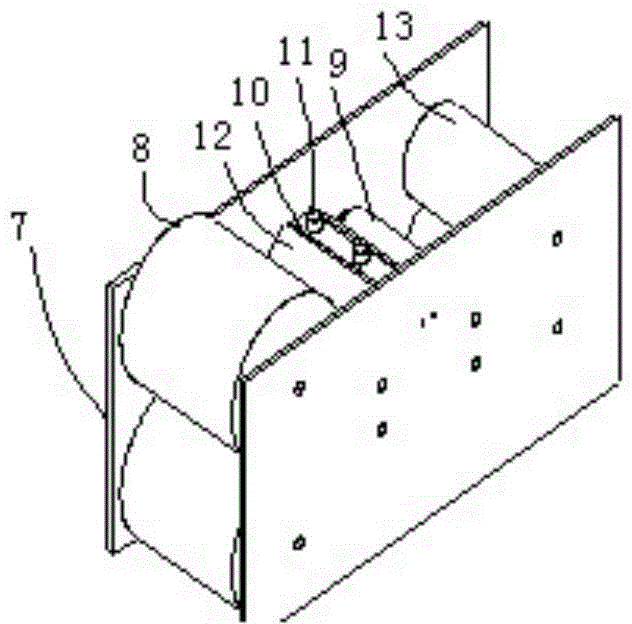

[0042] Processing equipment such as Figure 4As shown, it is composed of a pair of thermal insulation heating rollers 13, two pairs of positioning rollers 9 and a pair of shaping rollers 8, and the spraying part 10 between the two pairs of positioning rollers 9. The spraying unit 10 is located on both sides of the surface of the bipolar plate, which can realize the treatment of both sides of the bipolar plate. The side of the spraying part facing the bipolar plate is provided with a nozzle, the other side is provided with a raw material inlet, and a baffle is provided between the positioning roller and the spraying part. ° Angle, its width is advisable to cover the gap between the injection part and the positioning roller. The diameter of the two positioning rollers is 0.3m, and the distance between them is 1.3mm and 0.9mm respectively; the diameter of the two heating rollers is 0.5m, and the distance between them is 0.9mm; The upper and lower sides of the bipolar plate are ...

Embodiment 2

[0044] The size of the processing device is as follows: the diameter of two positioning rollers is 0.3m, and the distance between them is 1mm and 0.8mm respectively; the diameter of two heating rollers is 0.5m and the distance between them is 0.8mm; The side is equipped with a spraying part structure, and the upper part of the spraying part is arranged with three feeding ports side by side. The diameter of the feeding port is 10cm, the diameter of the spraying head is 5mm, the distance between the spraying heads is 10mm, and 50 spraying heads are arranged side by side. Compressed air is used as the conveying gas, and the conveying pressure is 0.08kPa. The powdered carbon material with a particle size of 0.02mm and the bonding agent (mass ratio: 91:9) are continuously injected into the feed port. The powdered carbon material is sprayed and deposited on the surface of the just-prepared bipolar plate, and the spraying frequency is consistent with the running speed of the bipolar p...

Embodiment 3

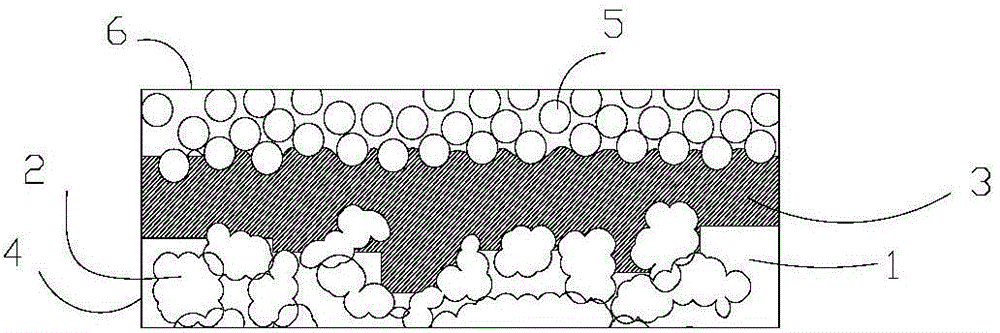

[0046] The dimensions of the processing device are as in Example 1. Compressed air is used as the conveying gas, and the conveying pressure is 0.08kPa. The powdered carbon material with a particle size of 0.015mm, titanium metal particles and bonding agent (mass ratio: 85:10:5) are continuously injected into the feed port. Under the action of air pressure, the powdered carbon material is sprayed and deposited on the surface of the just-prepared bipolar plate, and the spraying frequency is consistent with the running speed of the bipolar plate. The obtained low contact resistance bipolar plate for the flow battery is as follows: the thickness of the bipolar plate is 0.8 mm, the material is pp+30% carbon, the thickness of the high conductive flexible surface layer increased on both sides is 0.1 mm, and the material of the flexible surface layer is weight Than 85% carbon powder, 10% metal and 5% bonding aid (PvDF). The bipolar plate prepared by this method was assembled on a 3kW...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com