Method for treating waste by adopting microwave plasma

A microwave plasma and microwave plasma technology, applied in separation methods, solid waste removal, gas treatment and other directions, can solve the problems of high energy consumption, complex procedures, poor stability, etc., and achieve the effects of high efficiency and simple treatment procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

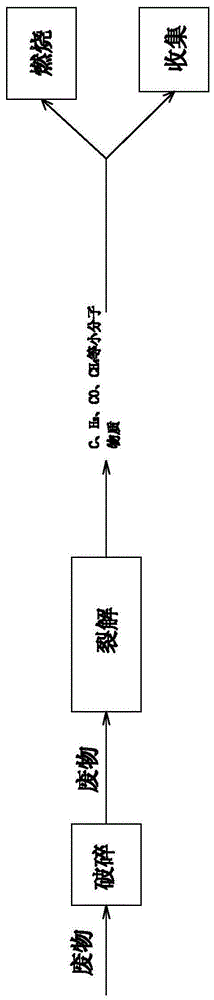

[0017] refer to figure 1 , the present invention is a kind of microwave plasma torch treatment waste method, comprises the following steps:

[0018] a. Waste pretreatment: the solid waste is crushed through the crushing device, and the liquid and gaseous waste are directly sent to the next step;

[0019] b. Pyrolysis, the gas is plasmaized by microwave plasma generating device to generate plasma torch, the gas can be air, nitrogen, oxygen, hydrogen or the above mixed gases, the temperature of the torch is controlled at 1500°C-5000°C according to the characteristics of the waste In the range of ℃, the waste pretreated by the plasma torch is used for high-energy pyrolysis, and the organic matter is pyrolyzed to produce C, H 2 , CO, CH4 and other small molecular substances, inorganic substances are melted into glassy substances by high temperature;

[0020] In the present invention, the plasma torch generated by the plasma generating device is used to crack the waste, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com